Circuit board and method of manufacturing circuit board

A technology of circuit substrate and manufacturing method, which is applied in the directions of printed circuit manufacturing, multilayer circuit manufacturing, printed circuit dielectric, etc., can solve problems such as inability to ensure the insulation of metal shells, achieve the effect of improving insulation and realizing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

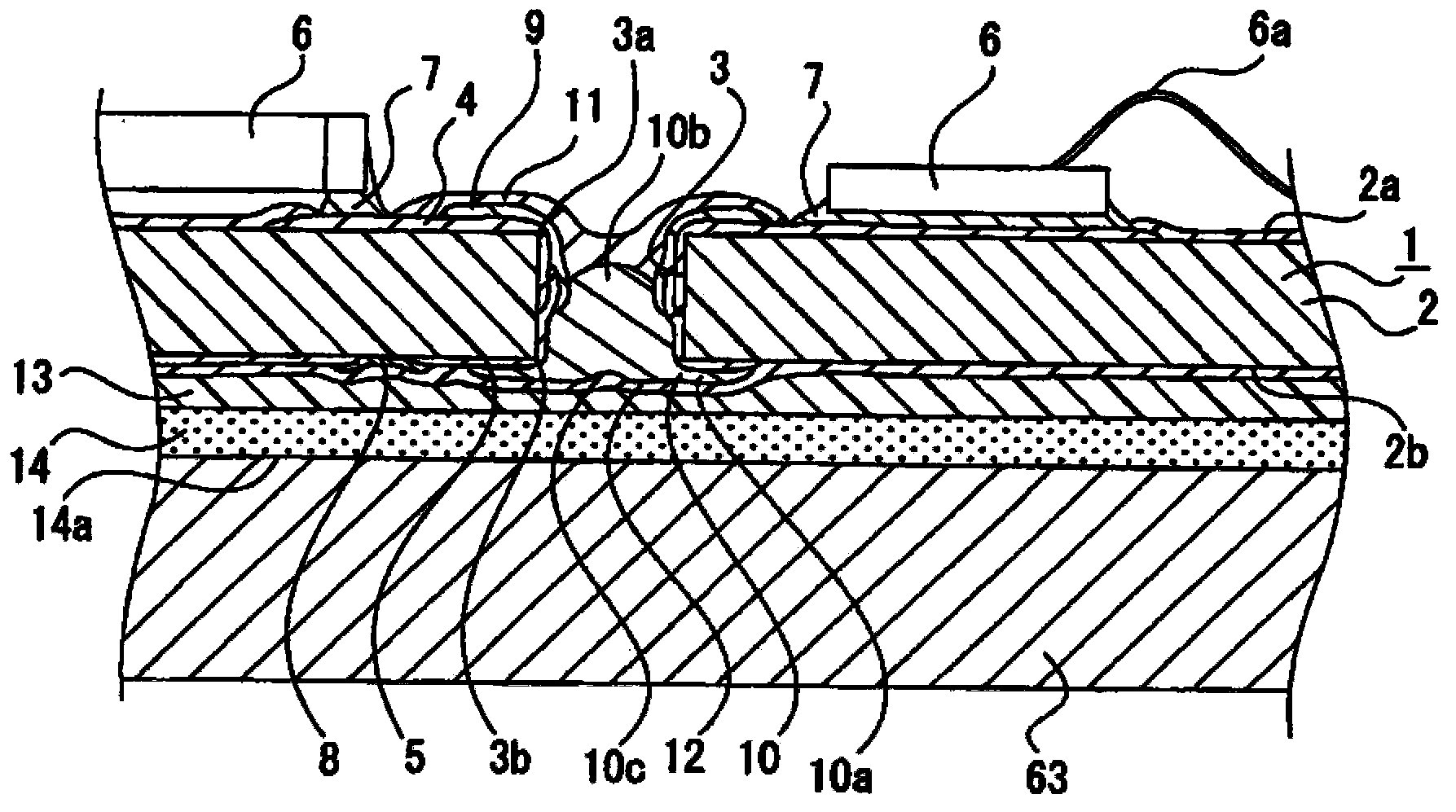

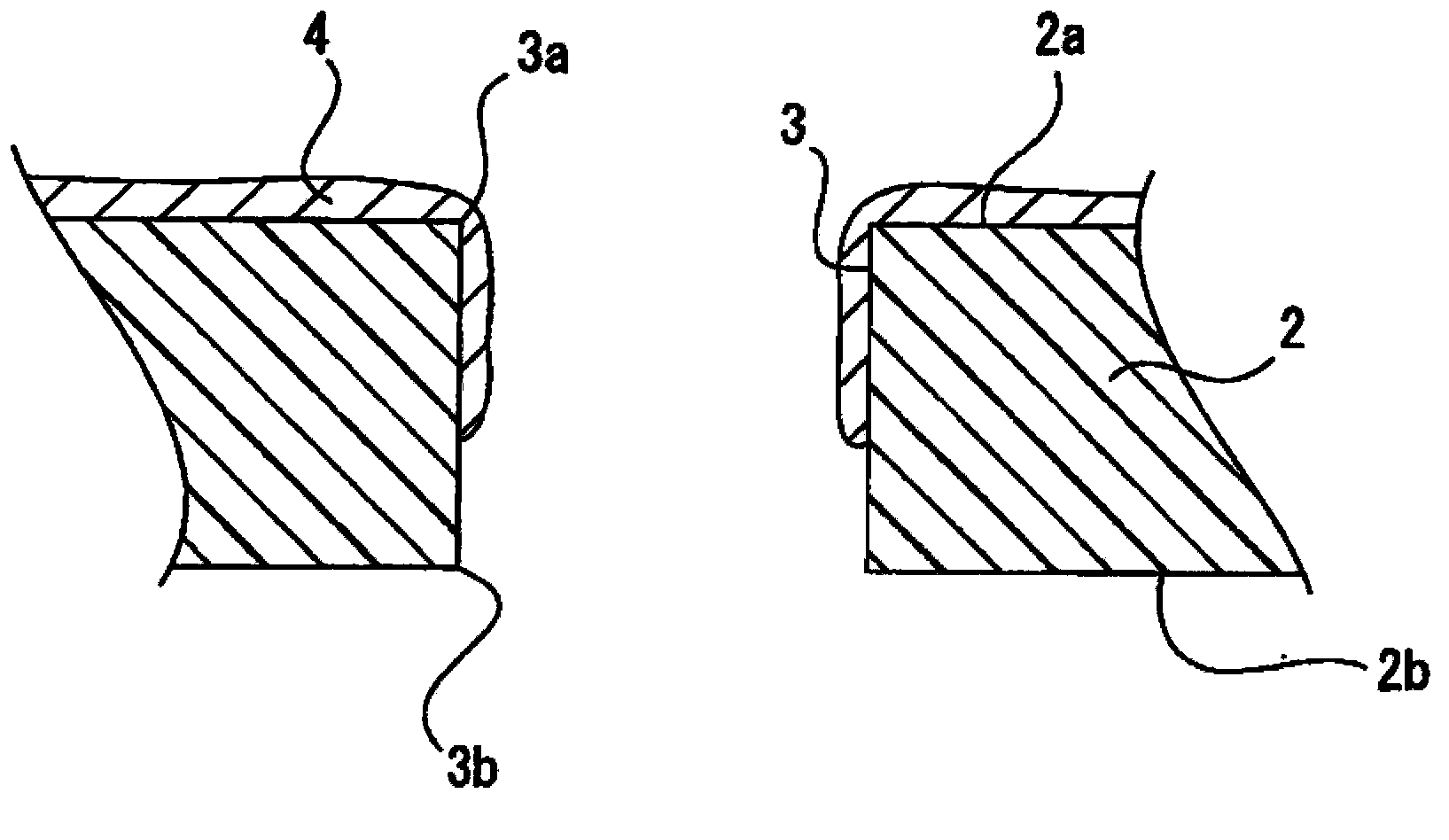

[0043] Hereinafter, preferred embodiments for carrying out the present invention will be described with reference to the drawings.

[0044] In the following description, the direction in which the light source of the vehicle lamp provided with the circuit board faces, that is, the direction in which light is emitted from the light source, is referred to as the front, and the front, rear, up, down, left, and right directions are indicated.

[0045] In addition, the directions of front, back, up, down, left, and right shown below are assumed for convenience of description, and implementation of the present invention is not limited to the above directions.

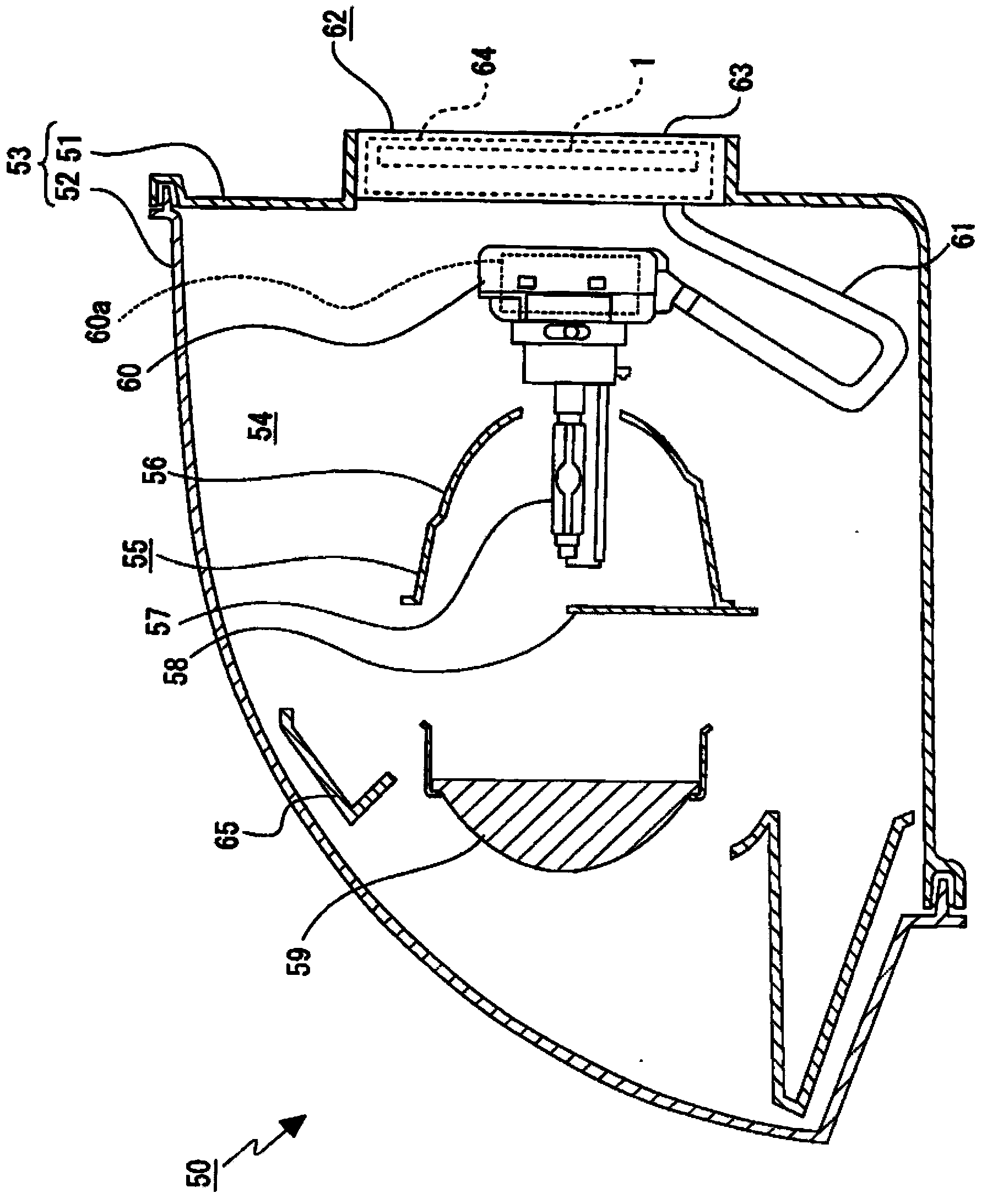

[0046] The circuit board 1 is provided, for example, as a part of electrical components arranged in a vehicle lamp 50 such as a vehicle headlamp.

[0047] The vehicle lamps 50 are mounted on both left and right ends of the front end of the vehicle body.

[0048] Vehicle lamps 50 such as figure 1 The shown lamp body 51 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com