Quick drag hook reset mechanism of dobby shedding device

A technology of opening device and reset mechanism, which is used in dobby machines, textiles, textiles and papermaking, etc., can solve the problems of unsatisfactory falling speed and easy wear and tear of parts, and achieve the effect of rapid fall back and reset and avoid wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

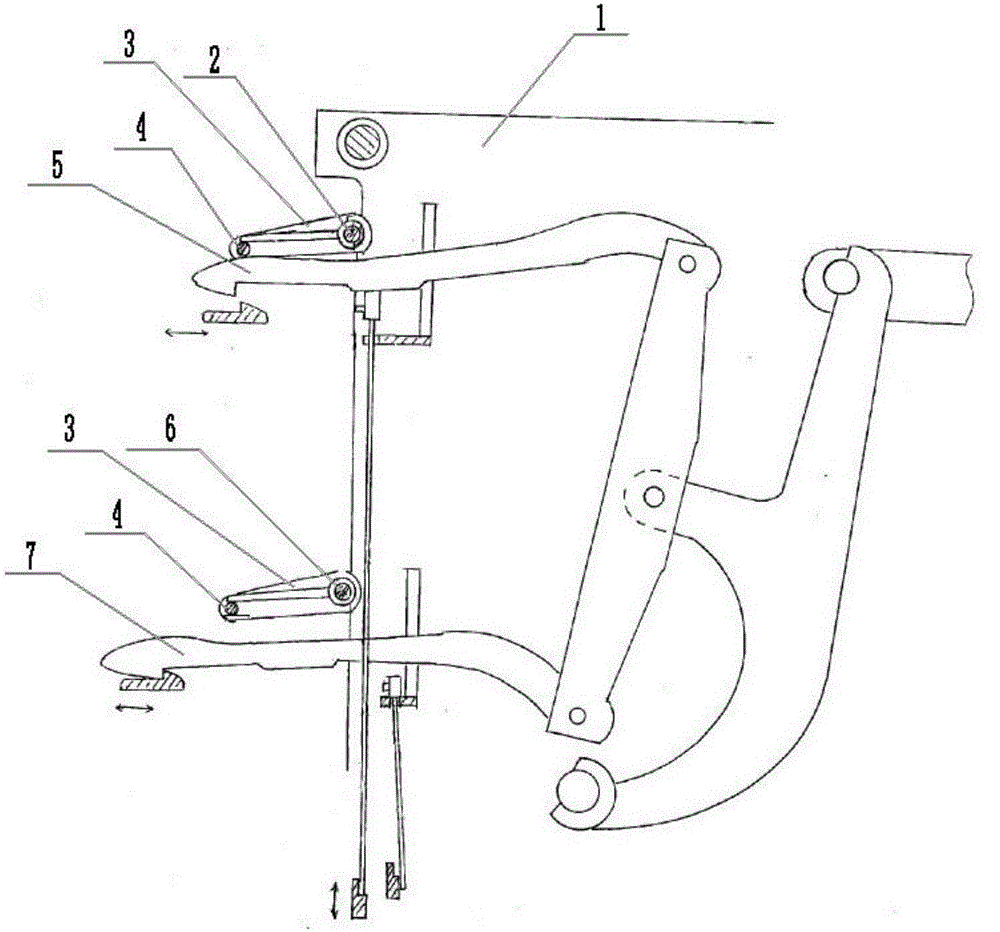

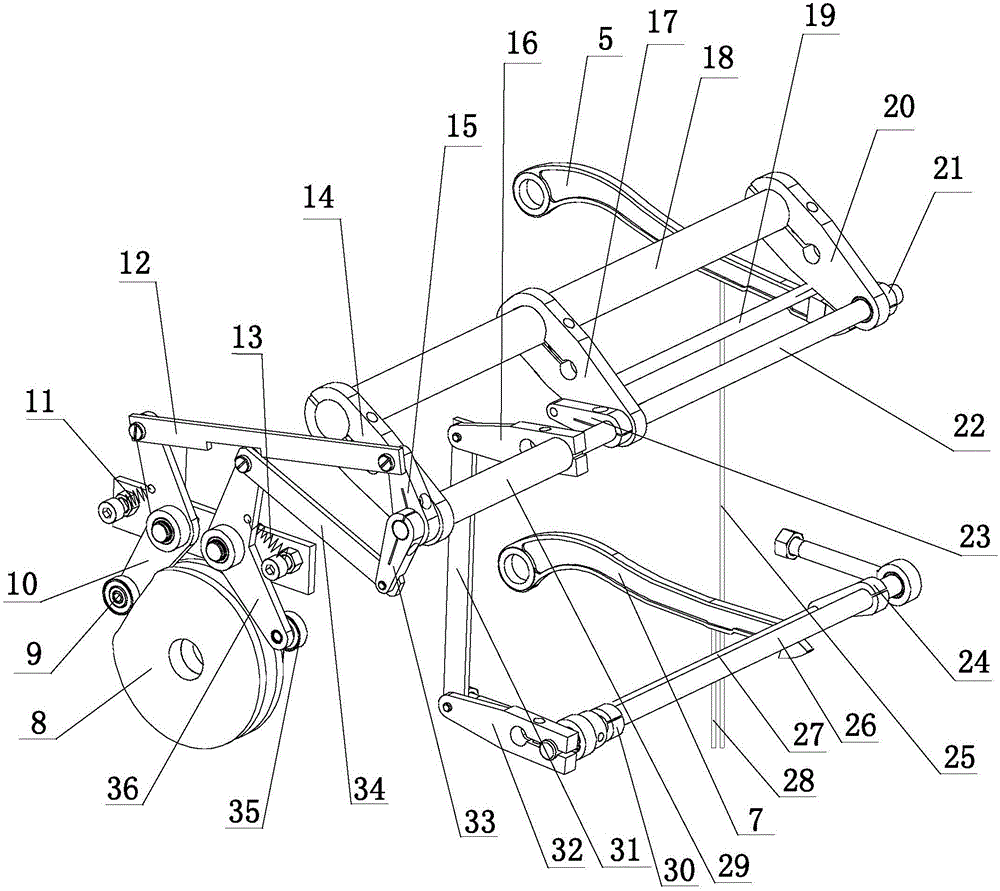

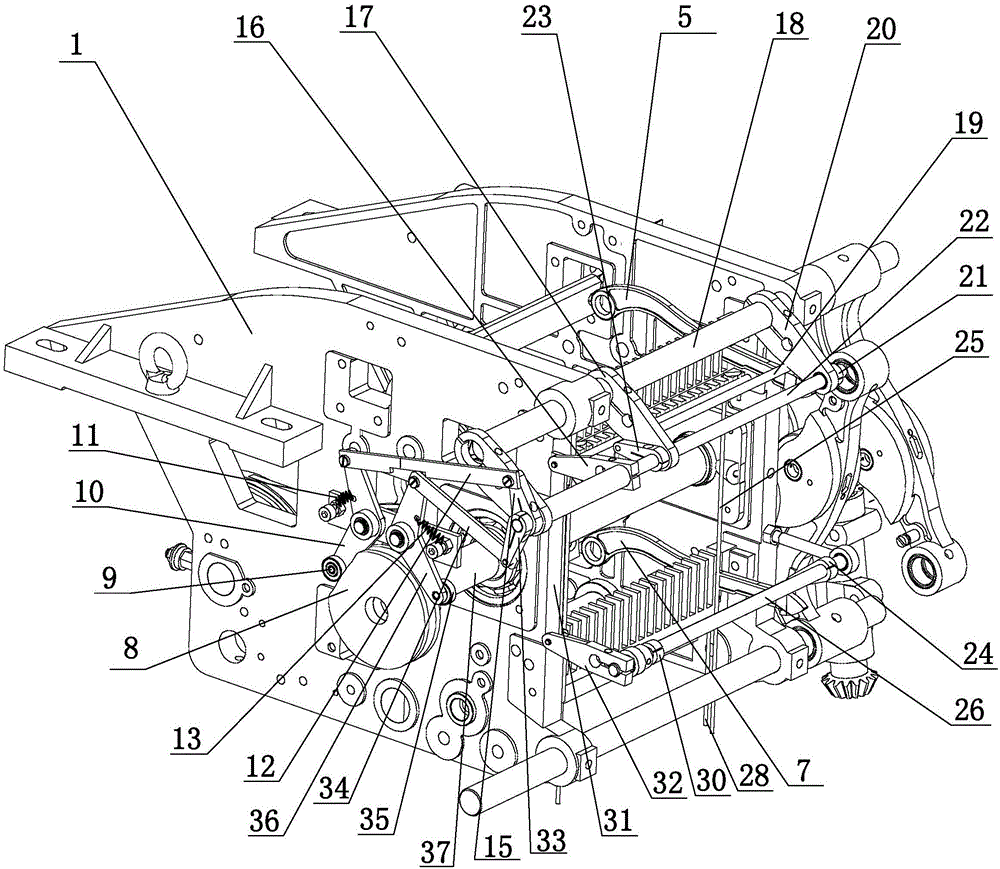

[0020] Such as Figure 1~Figure 3 As shown, the multi-arm opening device of the present invention includes a pair of wall panels 1, a group of upper hooks 5, a group of lower hooks 7, an upper knife, a lower knife, and the length equal to the number of upper hooks 5. Vertical needles 25, short vertical needles 28 equal in number to the pull-down hooks 7, and a pull hook quick reset mechanism, a pair of wall panels 1 are opposite to each other, and a set of upper pull hooks 5 and a set of pull-down hooks 7 are located between the wall panels 1 And be arranged up and down, one upper broach is set correspondingly with described one group of upper hooks 5, one lower knife is correspondingly set with described one group of lower hooks 7, and the front ends of each upper hooks 5 match with upper broaches, each The front end of the pull-down hook 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com