Check valve device of vortex compressor

A technology of scroll compressors and check valves, applied in the field of scroll compressors, can solve problems such as the inability to solve high-pressure gas backflow, achieve the effects of preventing reverse rotation, reducing impact or impact, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

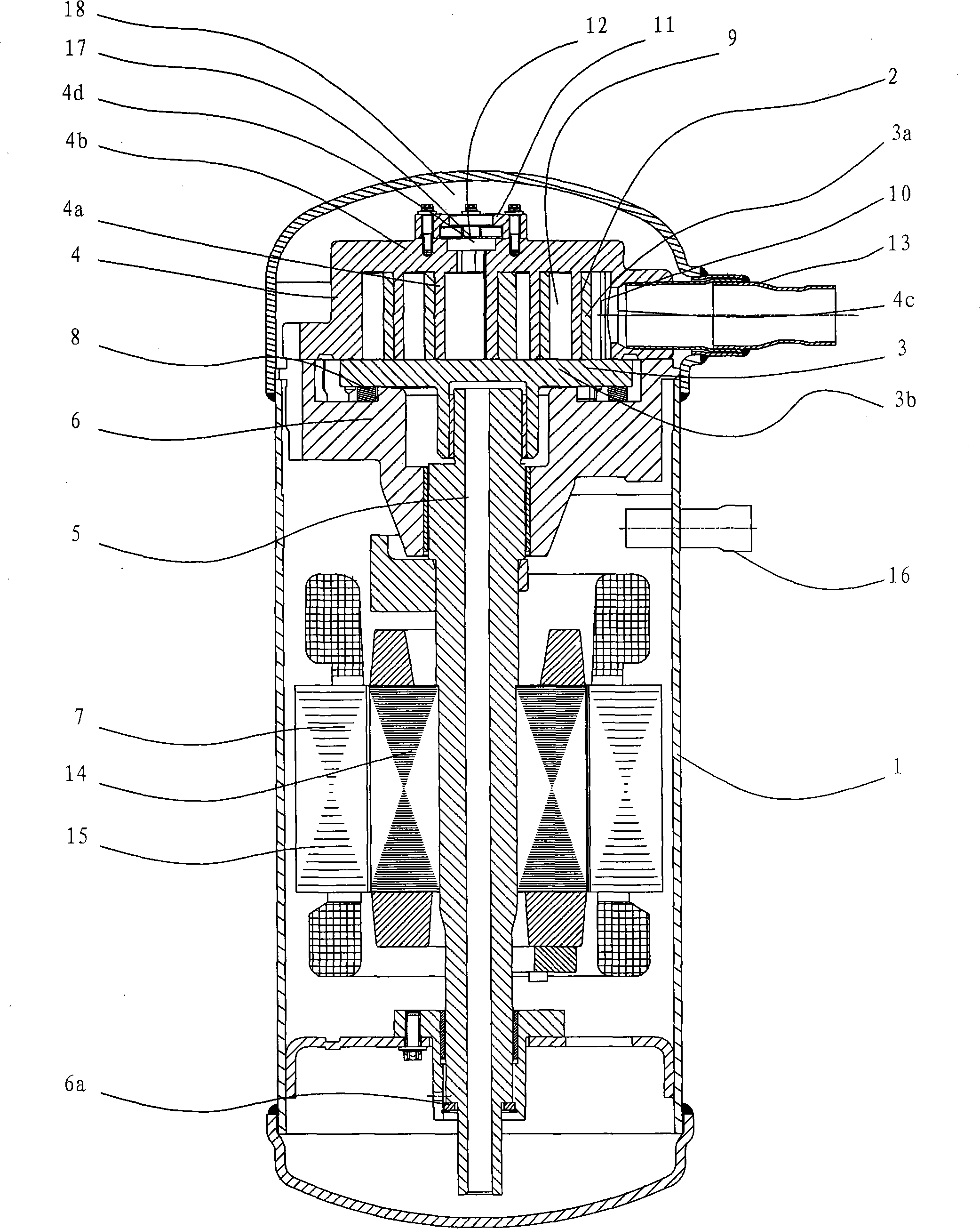

[0034] see figure 2 , is the vertical section view of the scroll refrigeration compressor.

[0035] In the scroll compressor, the compression mechanism unit 2 and the motor unit 7 are connected by a crankshaft 5 and accommodated in the airtight container 1 . The compression mechanism part 2 includes a fixed scroll 4 , a movable scroll 3 , a frame 6 , a crankshaft 5 and an Oldham slip ring 8 as main components.

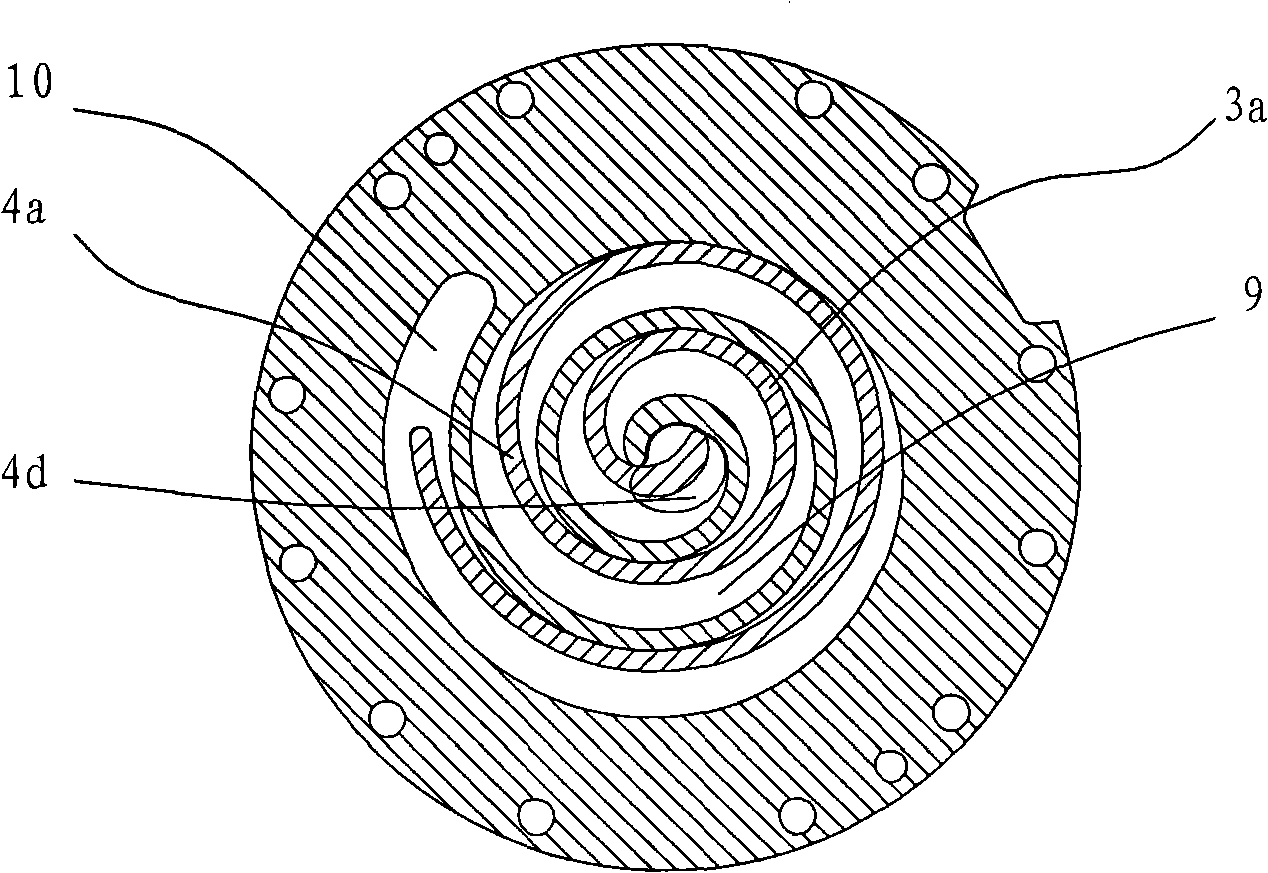

[0036] The fixed scroll 4 has a fixed scroll end plate 4b and a spiral fixed scroll 4a standing upright on the fixed scroll end plate 4b. The fixed scroll 4 is fastened on the upper side of the frame 6 by screws. The periphery of the frame 6 is fixed on the airtight container 1, and the lower part of the airtight container 1 has a bearing 6a for supporting the rotation of the crankshaft 5. A suction port 4c is provided on the outer peripheral portion of the fixed scroll 4 . The suction port 4c is parallel to the fixed scroll end plate 4b. A suction pipe 13 connec...

no. 2 example

[0052] see Figure 9 , the elastic buffer device includes a valve seat composed of an upper valve seat 11f and a lower valve seat 11g, the shoulder 11m and the air return hole 11d are located on the upper valve seat 11f, and the upper valve seat and the lower valve seat 11g together form a guide inner hole 11c and an annular positioning groove, the cross section of which is ∩ or ∏-shaped; the second buffer piece 11h is ring-shaped, and the cross section of the second buffering piece 11h is ∩ or Π-shaped, and the outer side of the second buffering piece 11h is embedded Located in the positioning groove, the inner side of the second buffer member 11h is located in the guide inner hole 11c, and the inner diameter of the second buffer member 11h is smaller than the outer diameter of the valve plate 12 and larger than the inner diameter of the air return hole 11b.

[0053] The outer side of the shoulder 11m is provided with a discharge port 11e, the discharge port 11e is located on...

no. 3 example

[0059] see Figure 10 , the elastic buffer device includes a third buffer member 11k, the third buffer member 11k is located in the guide hole 11c and fitted under the shoulder 11m, the third buffer member 11k is ring-shaped, and the inner diameter of the third buffer member 11k is less than The outer diameter of the valve plate 12 is greater than the inner diameter of the air return hole 11b, and the outer wall of the third buffer member 11k is attached to the inner wall of the guide inner hole 11c. A discharge port 11e is provided on the outside of the retaining shoulder 11m, and the discharge port 11e is located on the valve seat 11. A communication channel 11j communicating with the discharge port 11e is provided at the lower part of the guide inner hole 11c, and the communication channel is located below the third buffer member 11k.

[0060] The bonding in this embodiment can be directly bonded with an adhesive, or a plurality of small pits can be dug under the shoulder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com