Disc hub assembly and dual mass flywheel

A dual-mass flywheel and disc hub technology, applied in the field of transmission, can solve the problems of large space requirements for the ring gear, complicated manufacturing and assembly of the ring gear, etc., and achieves the effects of easy implementation, low design cost, and easy manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

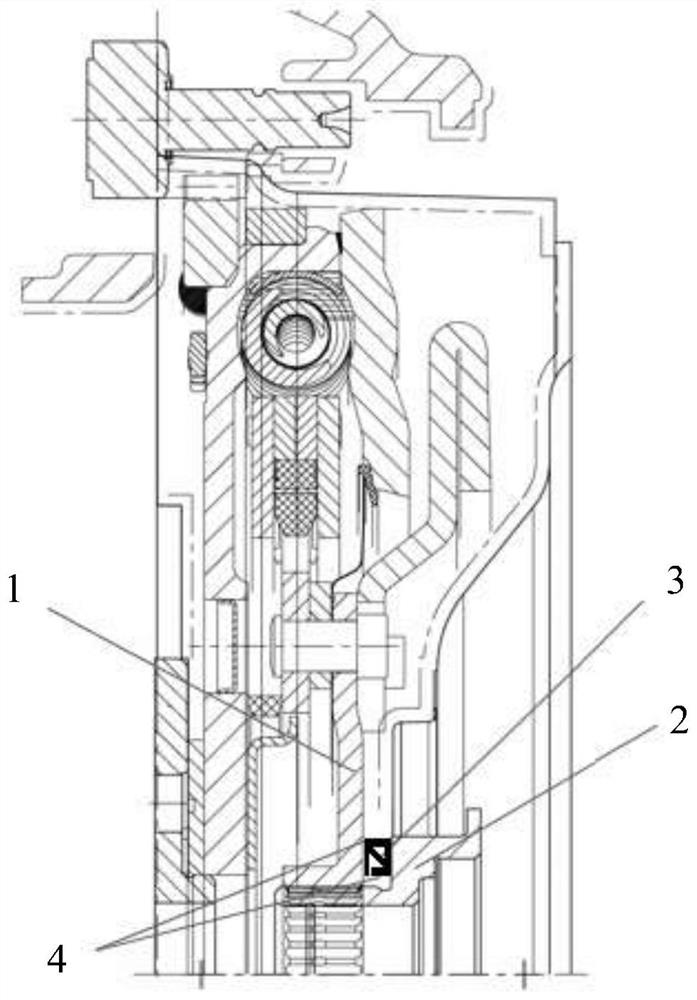

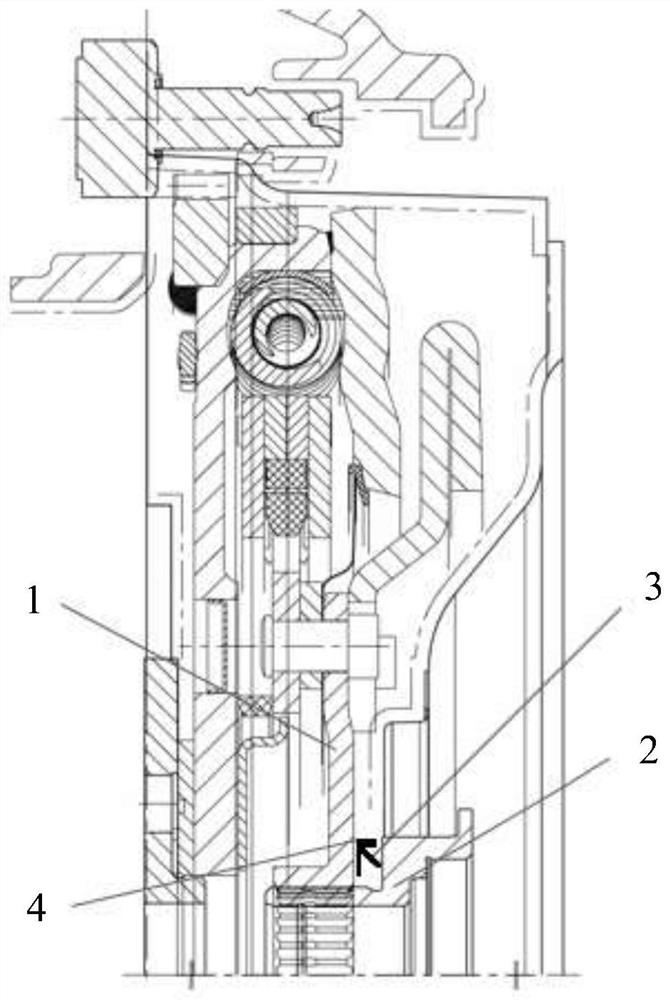

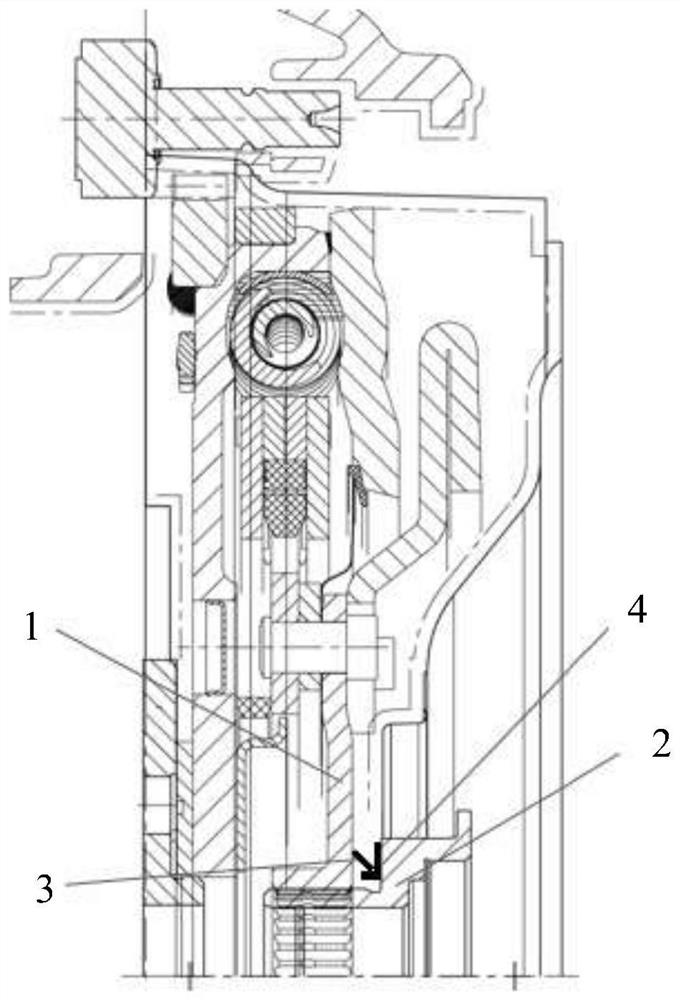

[0032] The following use the Figure 1 to Figure 4 A hub assembly in accordance with four embodiments of the present invention is shown. In various embodiments, the hub assembly may be constructed in a dual mass flywheel for a motor vehicle. The dual mass flywheel is arranged as a vibration damping device between the engine and the transmission of the motor vehicle to isolate torsional vibrations of the engine crankshaft. The transmission input shaft 2 of the transmission can be connected in a rotationally fixed manner to the secondary flywheel 1 . exist Figure 1 to Figure 4 Only one end of the transmission input shaft 2 is partially shown.

[0033] figure 1 A schematic half-sectional view of the disk-hub assembly according to the first embodiment in the state of connection with the transmission input shaft 2 is shown.

[0034] like figure 1 As shown, the hub assembly includes a hub serving as the secondary flywheel 1 of the dual mass flywheel. The secondary flywheel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com