Double-cylinder mutual pressuring prime motor

A technology of a prime mover and a cylinder is applied in the field of prime movers with dual-cylinder and dual-shaft output, which can solve the problems of polluting the environment, large energy consumption, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

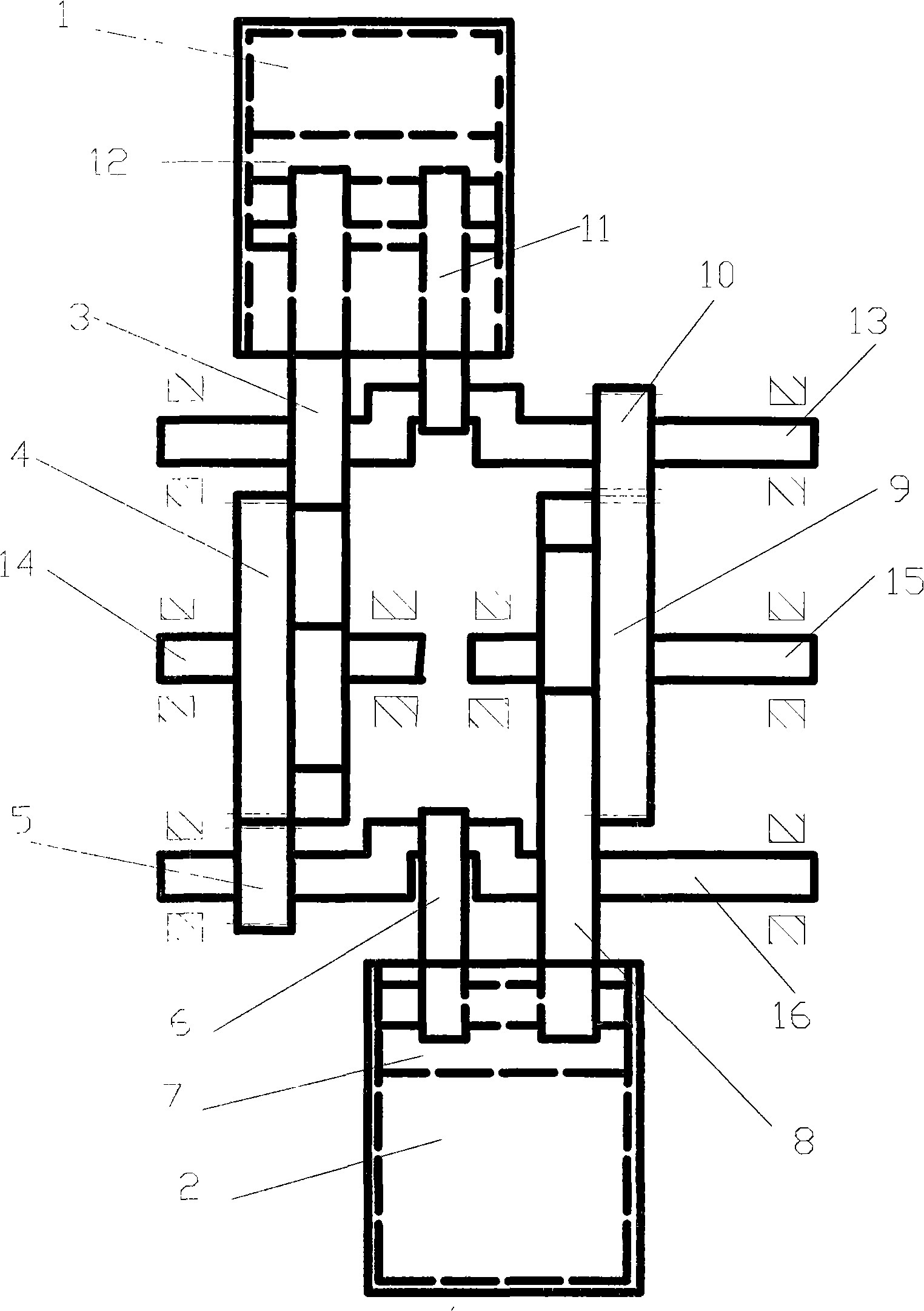

[0009] The following describes the embodiment of the twin-cylinder mutual pressure prime mover of the present invention in conjunction with the accompanying drawings and the symbols quoted in the accompanying drawings.

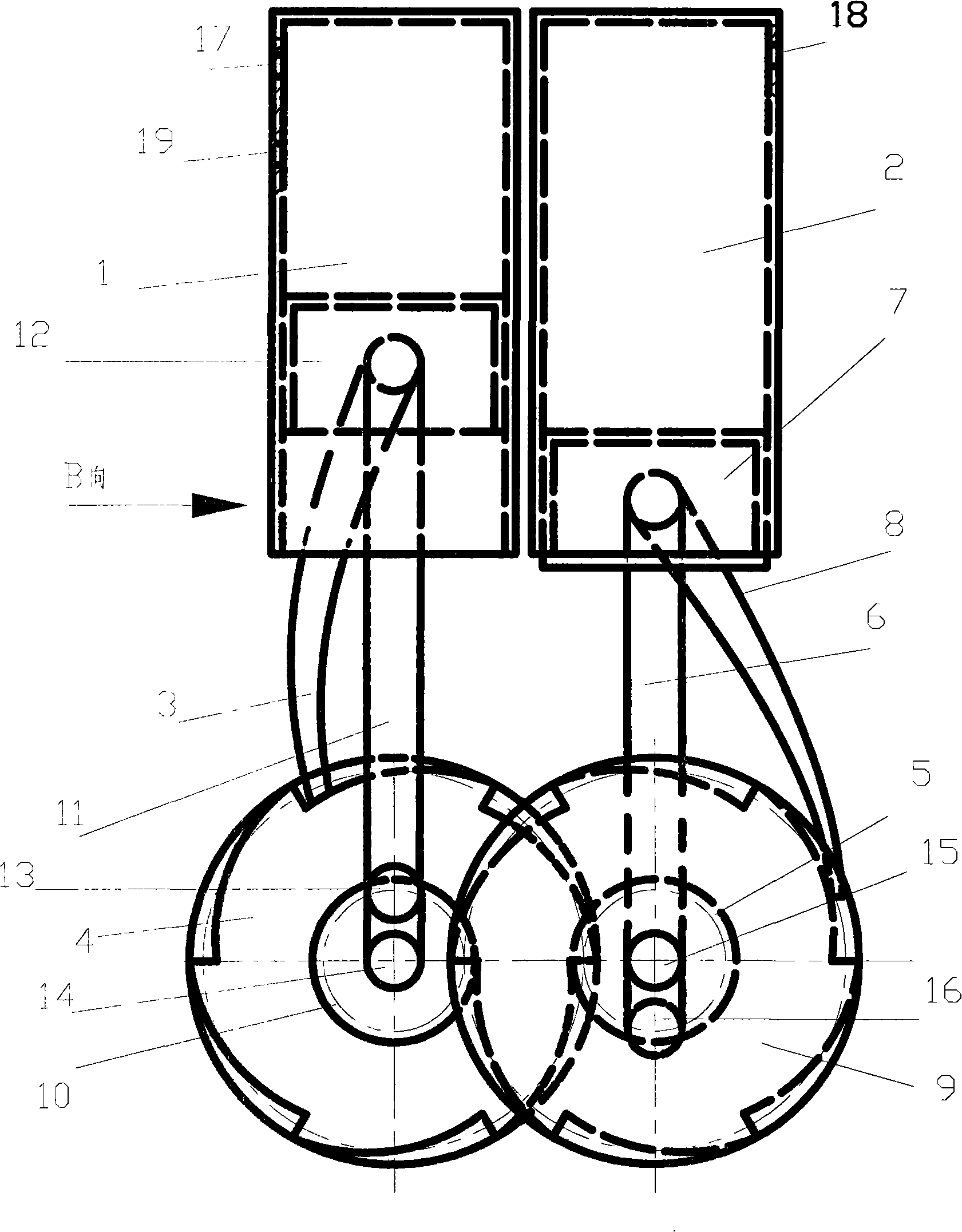

[0010] figure 1 It is a schematic diagram showing the main structure of the first embodiment of the twin-cylinder mutual pressure prime mover device of the present invention.

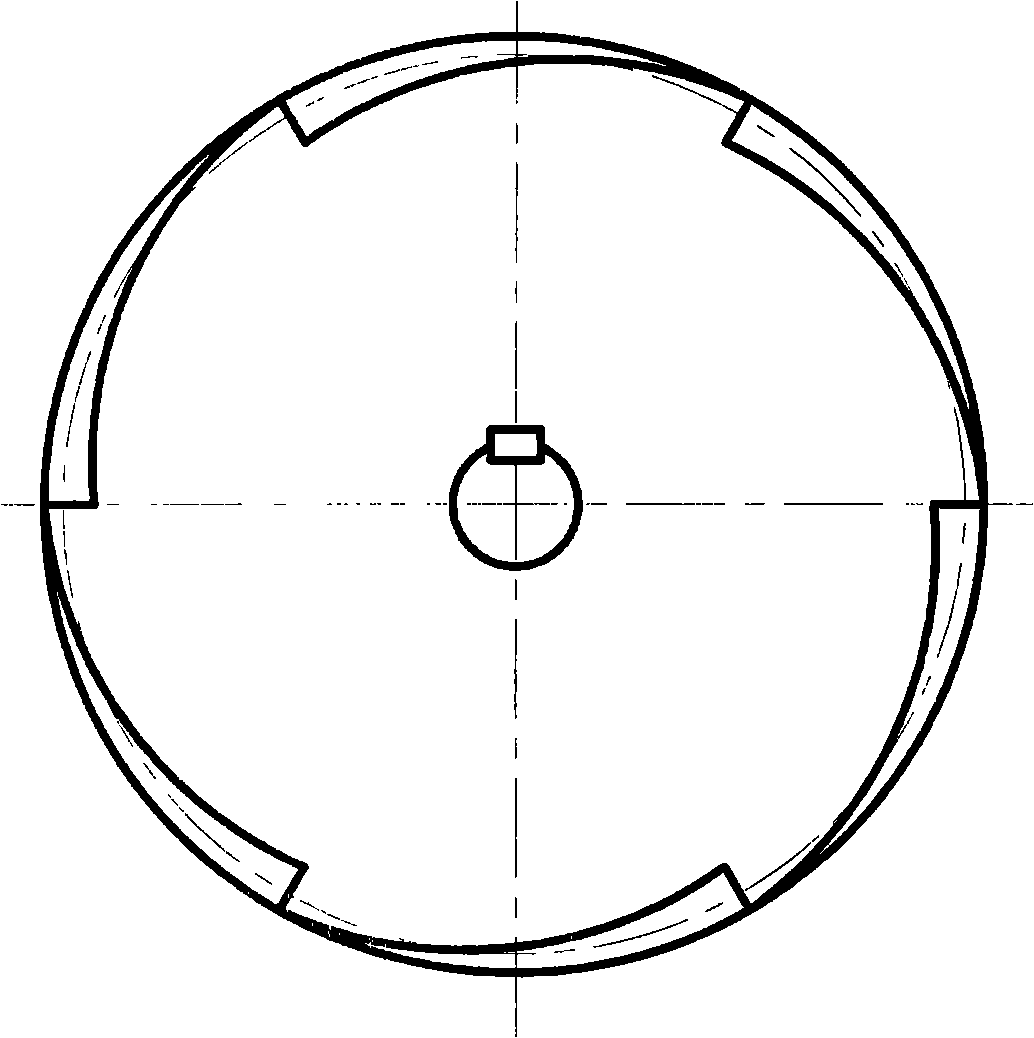

[0011] It includes cylinder 1, cylinder 2, piston 12, piston 7, pawl 3, pawl 8, connecting rod 11, connecting rod 6, compound wheel 4, compound wheel 9, pinion 10, pinion 5, crankshaft 13, crankshaft 16. Optical axis 14, optical axis 15, air intake hole 17 on cylinder 1, air intake hole 18 on cylinder 2, air release hole 19 on cylinder 1.

[0012] The concrete device of the first embodiment of double-cylinder mutual pressure prime mover is as follows:

[0013] The stroke distance of the piston 12 in the cylinder 1 is equal to the diameter length of the pinion 5 . A ratchet 3 and a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com