A bar processing derusting device and derusting method

A bar material processing and bar material technology is applied in the field of bar material processing and derusting device, which can solve the problems of bar material bending and bar surface damage, and achieve the effects of rapid recovery, simple structure and safe operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

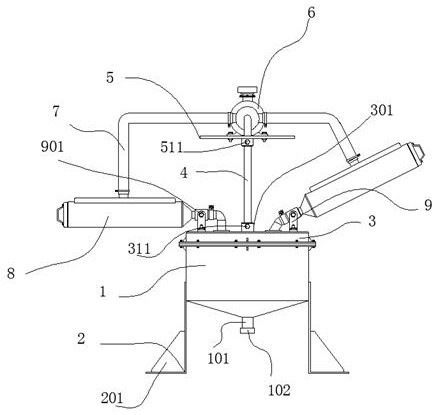

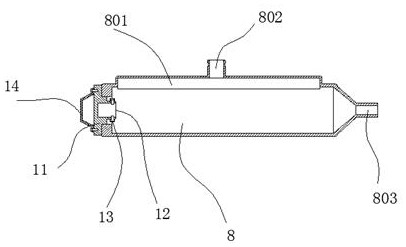

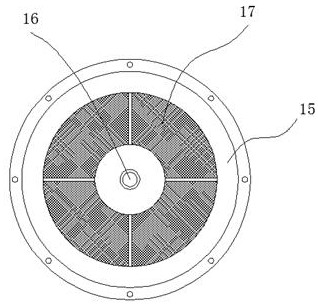

[0031] A bar processing derusting device, comprising a container 1, on the outer wall of the container 1, more than two support plates 2 are arranged annularly, and the bottom of the container 1 is provided with an outlet pipe 101 for exporting particles such as walnut sand , an end cap 102 is threadedly connected at the nozzle position of the outlet pipe 101, a tapered transition between the upper end of the outlet pipe 101 and the container 1; a cover cap is flange-connected at the upper end of the container 1 3. The axial center of the cover 3 is provided with an axial tube 301, and a negative pressure tube 4 is installed in the axial tube 301, and a coupling between the axial tube 301 and the negative pressure tube 4 The first screw 311, a supporting plate 5 is assembled on the outside of the negative pressure tube 4, a second screw 511 is fitted between the supporting plate 5 and the negative pressure tube 4, and the upper end of the supporting plate 5 is installed Negati...

Embodiment 2

[0033] A rib plate 201 is welded at an inner right angle position of the support plate 2 .

Embodiment 3

[0035] The length of the wind groove 801 is 4 / 5 of the length of the processing tube 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com