Tire uniformity improvement using estimates based on convolution/deconvolution

A uniformity, tire technology, used in automotive tire testing, design optimization/simulation, special data processing applications, etc., can solve problems such as unobtainable radial force change measurements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

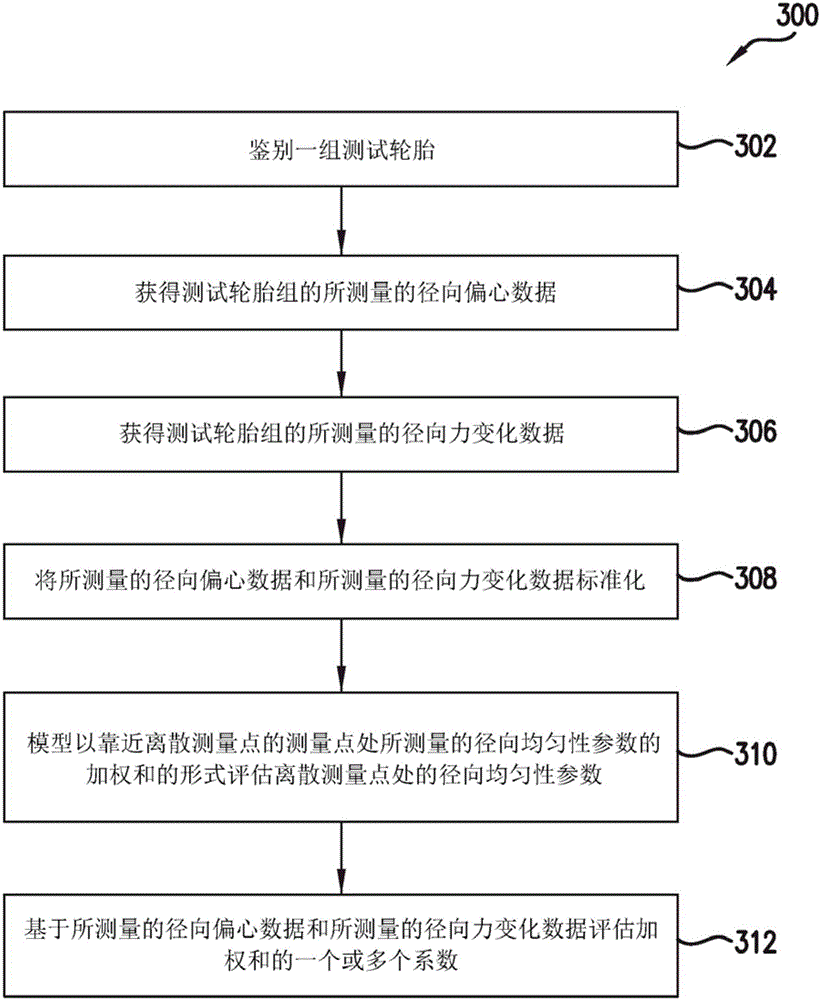

[0076] Radial eccentricity data for the center track of a set of four test tires and radial eccentricity data for three tracks were obtained. Obtain radial force variation data for the test tire set. Using the radial force variation data and the radial eccentricity data of the center trajectory, a first convolutional model is generated according to aspects of the invention. Radial force change data and radial eccentricity data for three trajectories were used. A second convolutional model is generated according to aspects of the invention. Evaluate the coefficients of the first and second convolutional models using regression analysis. Table 1 below compares the R of the first convolutional model and the second convolutional model 2 value (coefficient of determination) and RSME value (root mean square error).

[0077] Table 1

[0078]

[0079] As demonstrated, the convolutional model generated based on the center track radial eccentricity data provides a good model rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com