Rotary blade type dynamic steam-water separator with controllable rotational speeds

A steam-water separator and rotating blade technology, which are applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of separator separation efficiency and complex pressure loss, and achieve the elimination of tail vortex flow, high hardness and uniformity. The effect of distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

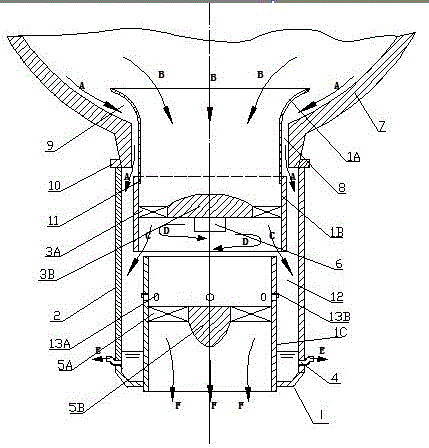

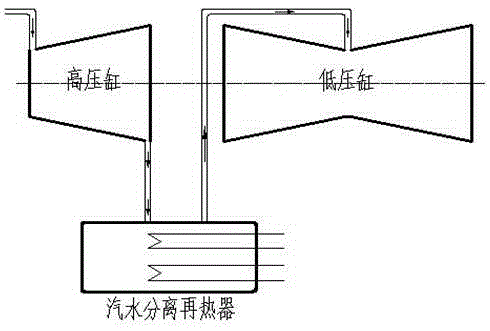

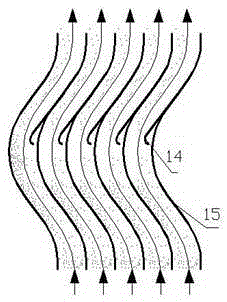

[0050] Combine below Attached picture The present invention will be further described in detail with specific embodiments. like figure 1 As shown, a rotating vane type controllable speed dynamic steam-water separator consists of a separation cylinder part, a rotating separation part, a droplet collection and drainage part and a dry steam axial flow recovery part, wherein:

[0051] The separation cylinder part includes an inner sleeve 1 and an outer cylindrical sleeve 2. The inner sleeve includes an upper separation cylinder 1A, a middle separation cylinder 1B, and a lower separation cylinder 1C extending into the exhaust port of the high-pressure cylinder. Between the entire inner and outer sleeves between of ring section, like figure 1 Shown is the separation chamber 12; the upper end of the upper separation cylinder 1A extends to the exhaust port of the high-pressure cylinder, and the upper end forms a trumpet tube form. The specific function of this form is: due t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap