A kind of high-sulfur bauxite desulfurization flotation activator

A high-sulfur bauxite and activator technology, used in flotation, solid separation, etc., can solve the problem of difficult mineral activation, and achieve the effect of eliminating the effect of sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

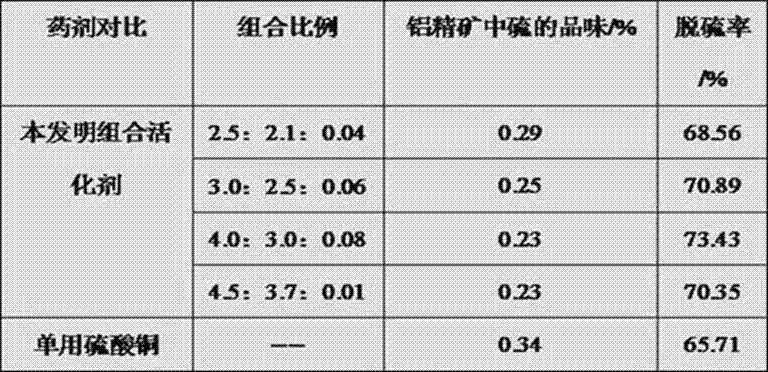

Embodiment 1

[0029] Step 1. Weighing the high-sulfur bauxite to be desulfurized and crushing it for later use;

[0030] Step 2. Weigh sodium carbonate, water glass and copper sulfate respectively according to the mass / number ratio of 2.5:2.1:0.04, and set aside;

[0031] Step 3. Transport the high-sulfur bauxite weighed in step 1 to the mill for grinding. During the grinding process, add the sodium carbonate weighed in step 2 until the high-sulfur bauxite with a particle size of -0.074mm Bauxite accounts for 85-90% and is reserved for use. The mass ratio of sodium carbonate to high-sulfur bauxite is (2.5-4.5): 1000;

[0032] Step 4. Add the water glass and copper sulfate weighed in step 2 to the high-sulfur bauxite in step 3, stir for 30 minutes to make slurry, then add xanthate desulfurization collector and foaming agent to it for floating Select and harvest for 17 minutes, and reserve;

[0033] Step 5. The mixture processed in step 4 is subjected to two rough, two fine and one sweep op...

Embodiment 2

[0035] Step 1. Weighing the high-sulfur bauxite to be desulfurized and crushing it for later use;

[0036] Step 2. Weigh sodium carbonate, water glass and copper sulfate respectively according to the mass / number ratio of 3.0:2.5:0.06, and set aside;

[0037] Step 3. Transport the high-sulfur bauxite weighed in step 1 to the mill for grinding. During the grinding process, add the sodium carbonate weighed in step 2 until the high-sulfur bauxite with a particle size of -0.074mm Bauxite accounted for 85~90, spare;

[0038] Step 4. Add the water glass and copper sulfate weighed in step 2 to the high-sulfur bauxite in step 3, stir for 30 minutes to make slurry, then add xanthate desulfurization collector and foaming agent to it for floating Select and harvest for 20 minutes, set aside;

[0039] Step 5. The mixture processed in step 4 is subjected to two rough, two fine and one sweep operations to obtain the product.

Embodiment 3

[0041] Step 1. Weighing the high-sulfur bauxite to be desulfurized and crushing it for later use;

[0042] Step 2. Weigh sodium carbonate, water glass and copper sulfate respectively according to the mass / number ratio of 4.0:3.0:0.08, and set aside;

[0043] Step 3. Transport the high-sulfur bauxite weighed in step 1 to the mill for grinding. During the grinding process, add the sodium carbonate weighed in step 2 until the high-sulfur bauxite with a particle size of -0.074mm Bauxite accounted for 85~90, spare;

[0044] Step 4. Add the water glass and copper sulfate weighed in step 2 to the high-sulfur bauxite in step 3, stir for 30 minutes to make slurry, then add xanthate desulfurization collector and foaming agent to it for floating Select and harvest for 17 minutes, and reserve;

[0045] Step 5. The mixture processed in step 4 is subjected to two rough, two fine and one sweep operations to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com