A special pipe for sawdust processing system

A processing system and sawdust technology, applied in the field of special pipes for sawdust processing systems, can solve the problems of affecting the air guiding speed, accumulation of dust in pipes, blockage, etc., and achieve the effects of reducing cleaning pressure, simple connection structure, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

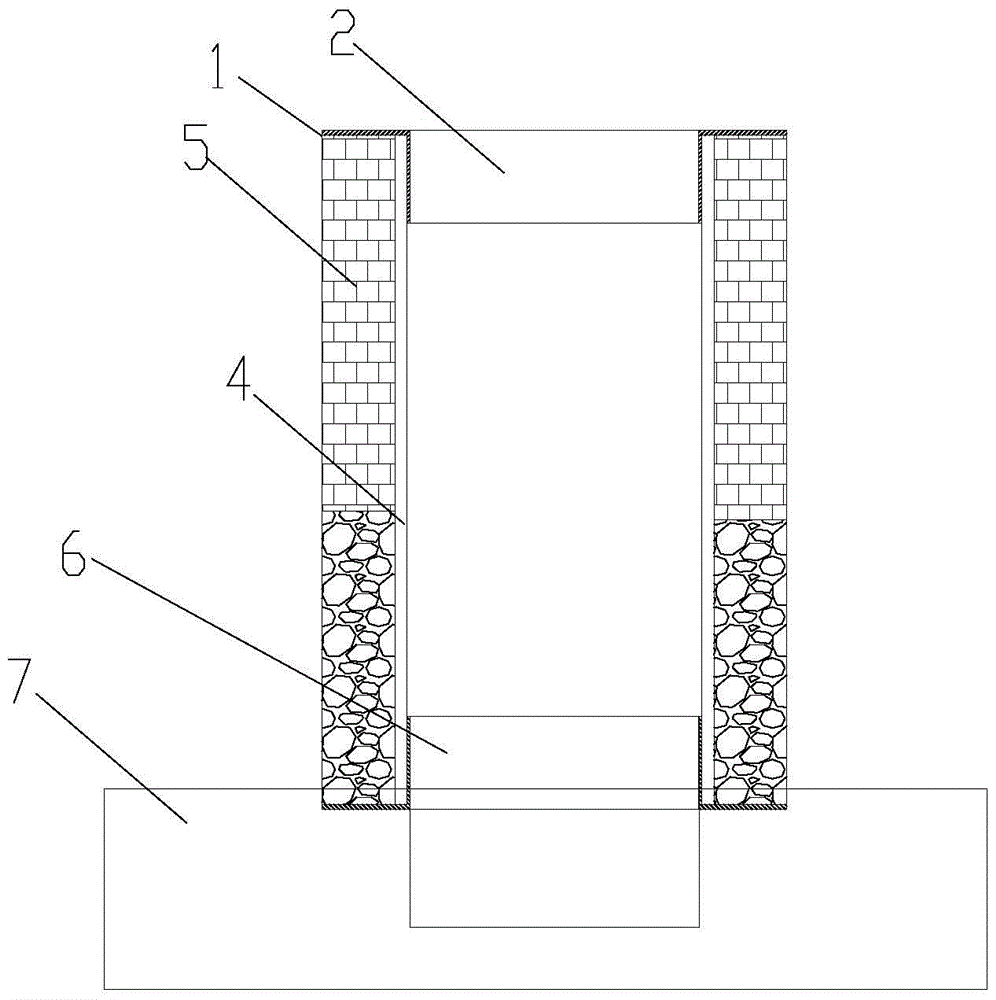

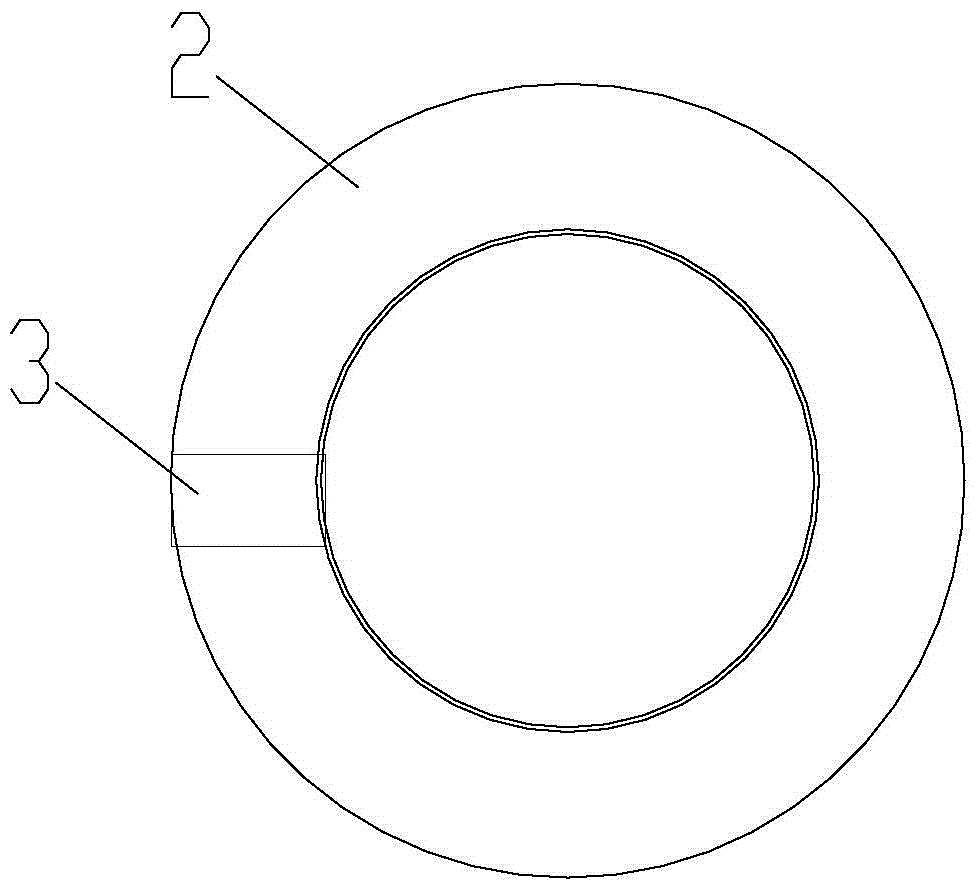

[0023] Such as figure 1 , figure 2 As shown, the present invention is a dedicated pipeline for wood chip processing system, including a pipe body 1, the top of the pipe body 1 is provided with an equipment installation slot 2, the equipment installation slot 2 is hollow, and there is at least one pipe body 1 equipment A high-temperature heating device is installed in the installation slot 2, and the high-temperature heating device can provide a heating temperature of 150-300 degrees Celsius without an open flame. The side of the device installation slot 2 is provided with a wire guide hole 3, and the wire guide hole 3 provides power supply and management for the equipment installed in the device installation slot 2. A cylindrical metal mesh 4 is installed inside the pipe body 1 , and the space between the metal mesh 4 and the pipe body 1 is filled with a high temperature resistant material 5 . The high temperature resistant material 5 is: mass percentage

[0024] Silicon c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com