RFID-based member relative displacement detection method

A technology of relative displacement and detection method, which is applied in the direction of computer parts, cooperative devices, instruments, etc., which can solve the problem of being easily affected by light, vibration, stains, etc., and the anti-loosening marks are easily covered by dust, oil, etc., and the technical difficulty is large. and other problems, to achieve the effect of small size, fast recognition speed and wide recognition range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

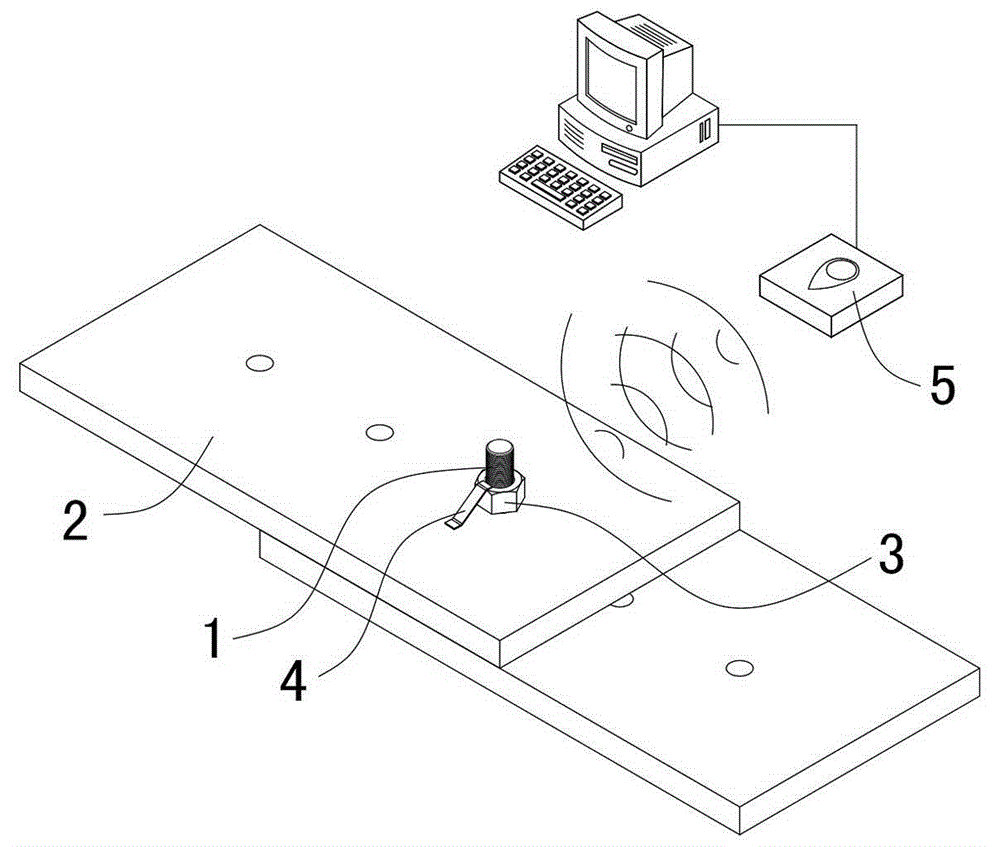

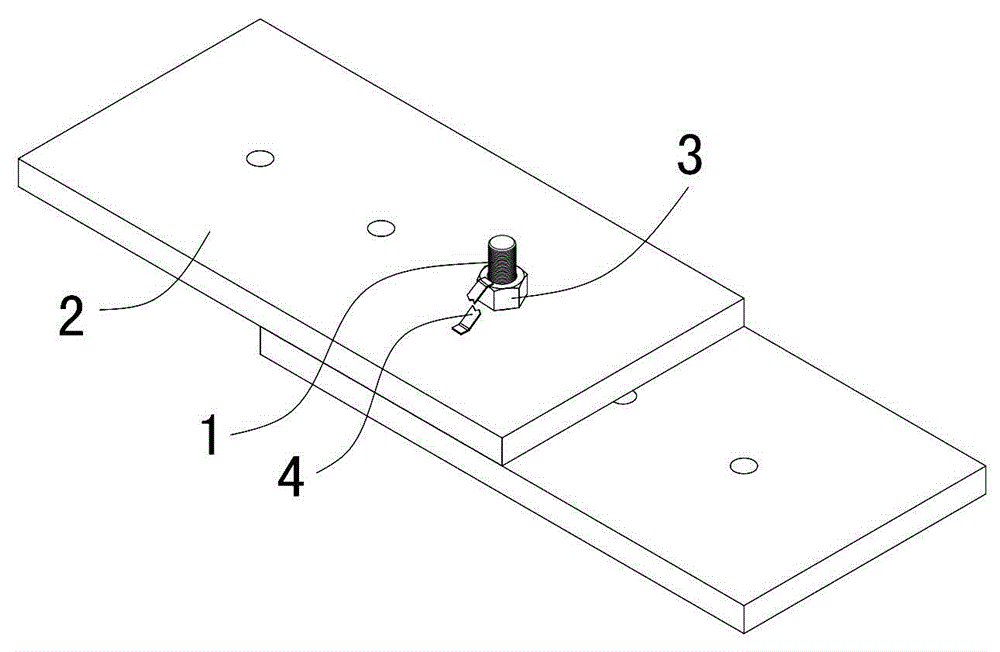

[0033] Hereinafter, taking the nut 3 of the bolt 1 and the installation base 2 of the bolt 1 as the components to be detected, and realizing the relative displacement detection between the nut 3 of the bolt 1 and the installation base 2 of the bolt 1 as an example, the RFID-based components of the present invention The relative displacement detection method is further described in detail.

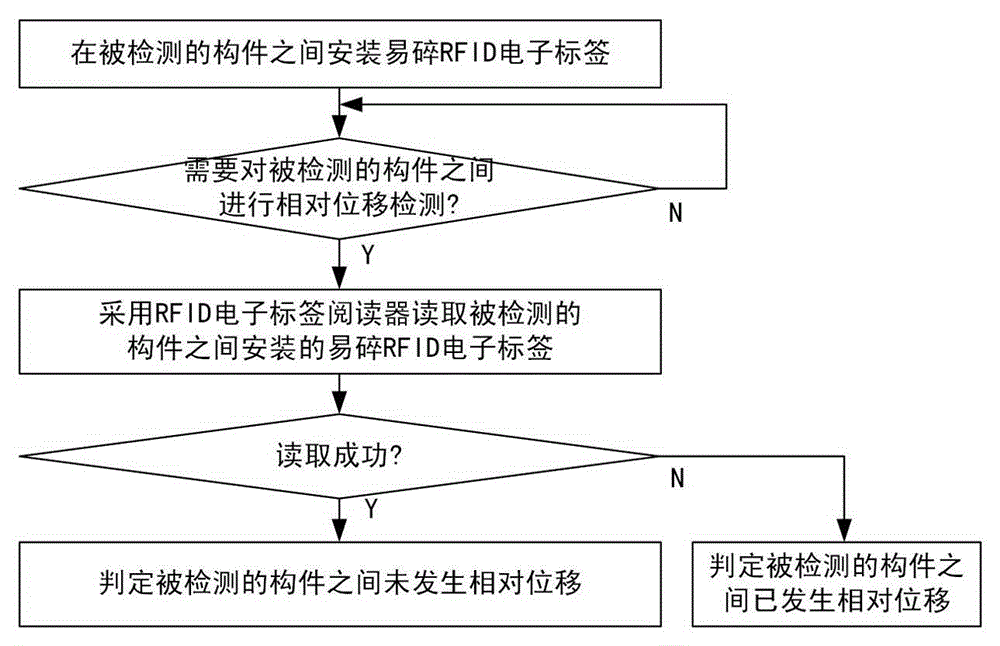

[0034] Such as figure 1 As shown, the steps of the RFID-based component relative displacement detection method in this embodiment include:

[0035] 1) Install fragile RFID electronic tags between the components to be detected in advance, so that the fragile RFID electronic tags are respectively connected and fixed with the components to be detected; see figure 2 , the bolt 1 is installed on the installation base 2, and the upper side of the bolt 1 is provided with a nut 3 that is threaded. The connection is fixed.

[0036] 2) When it is necessary to detect the relative displacement betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com