A three-dimensional neutron photographic nondestructive testing method for pressurized water reactor spent fuel elements

A non-destructive testing and spent fuel technology, applied in the field of nuclear material testing, can solve the problem of no three-dimensional neutron photography method, and achieve the effect of expanding the amount of non-destructive testing information, saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

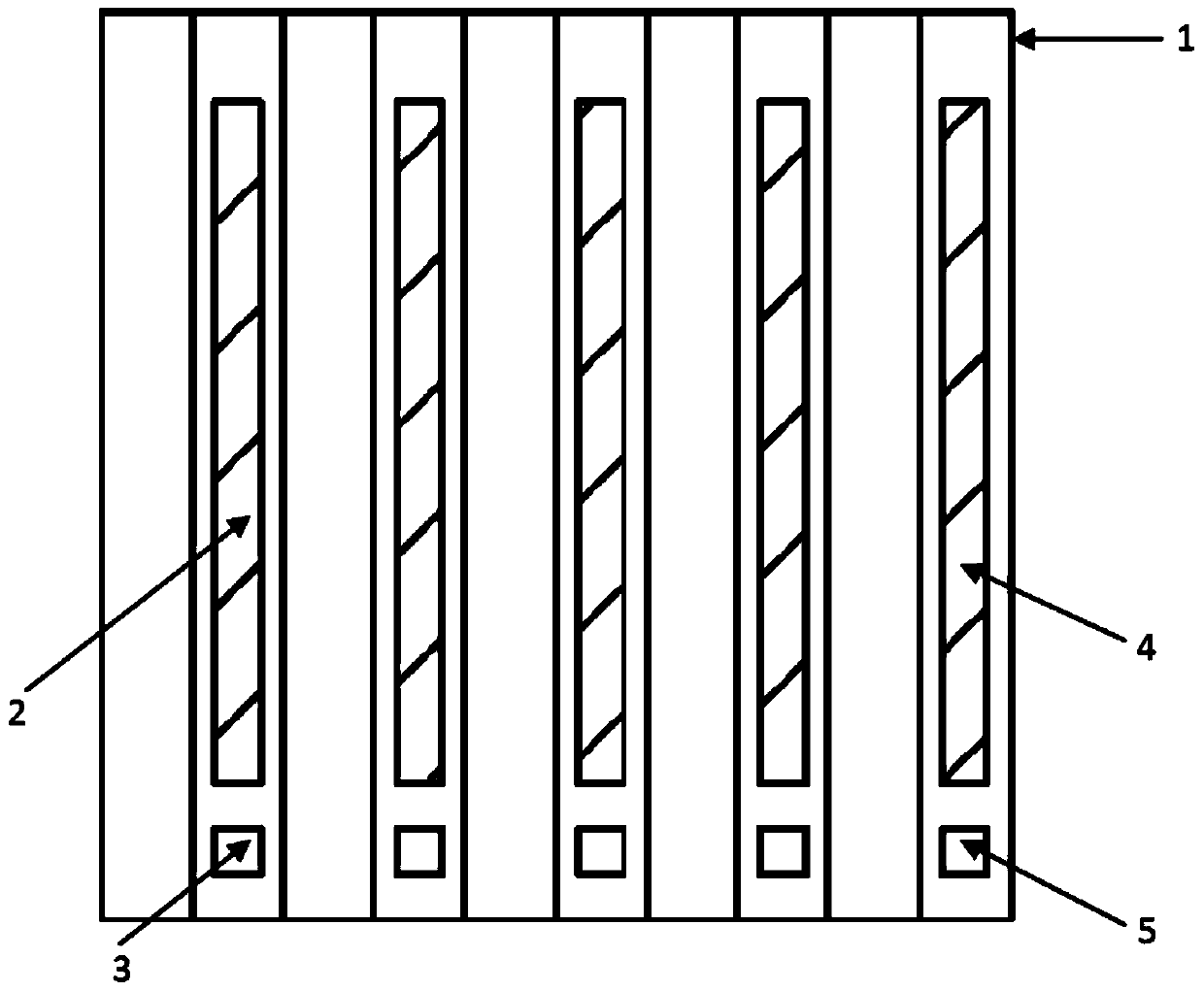

Image

Examples

Embodiment

[0027] Using the three-dimensional neutron photography non-destructive testing method of the PWR spent fuel component of the present invention to carry out non-destructive testing of a PWR nuclear fuel component, the steps are as follows:

[0028] (1) Place the neutron conversion screen behind the spent fuel element; the length of the spent fuel element is 15cm;

[0029] (2) Introduce a neutron beam in front of the spent fuel element. After the neutron beam passes through the spent fuel element, the neutron conversion screen is exposed to obtain a two-dimensional image of the spent fuel element. After a period of exposure, the neutron beam is removed flow; the size of the neutron conversion screen is 20cm×20cm×0.01cm;

[0030] (3) Translate the neutron conversion screen to change the projection position of the neutron beam passing through the spent fuel element on the neutron conversion screen. According to the size of the neutron conversion screen selected, each neutron conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com