Equipment for dividing tubular webs

A web and tubular technology, applied in the field of equipment for dividing tubular webs, can solve the problem of unreproducible pulling force, etc., and achieve the effect of improved production results, flexible and variable settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

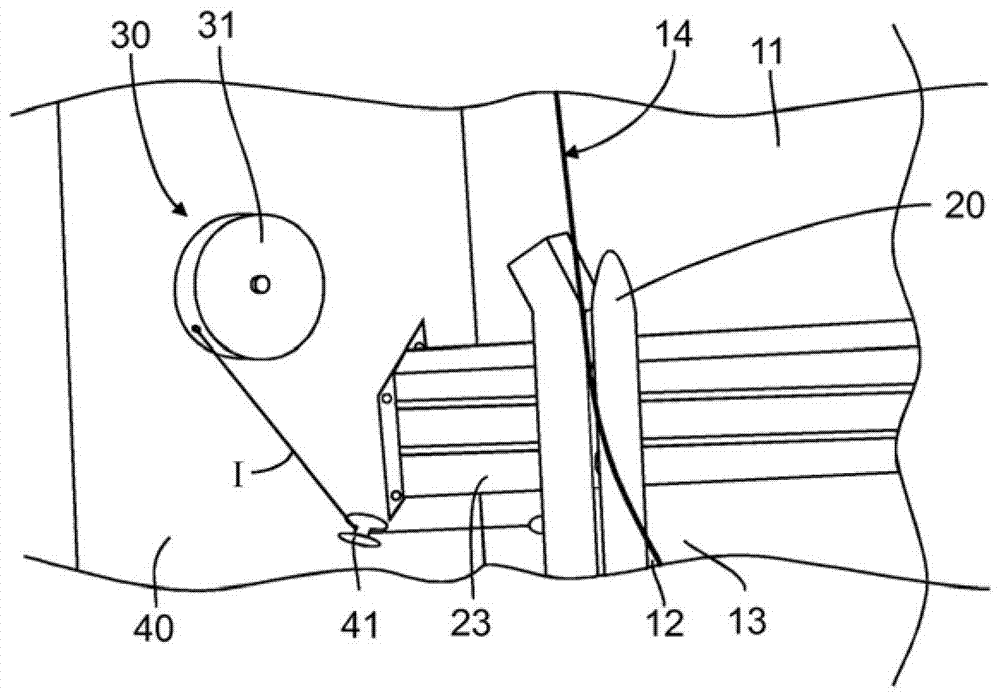

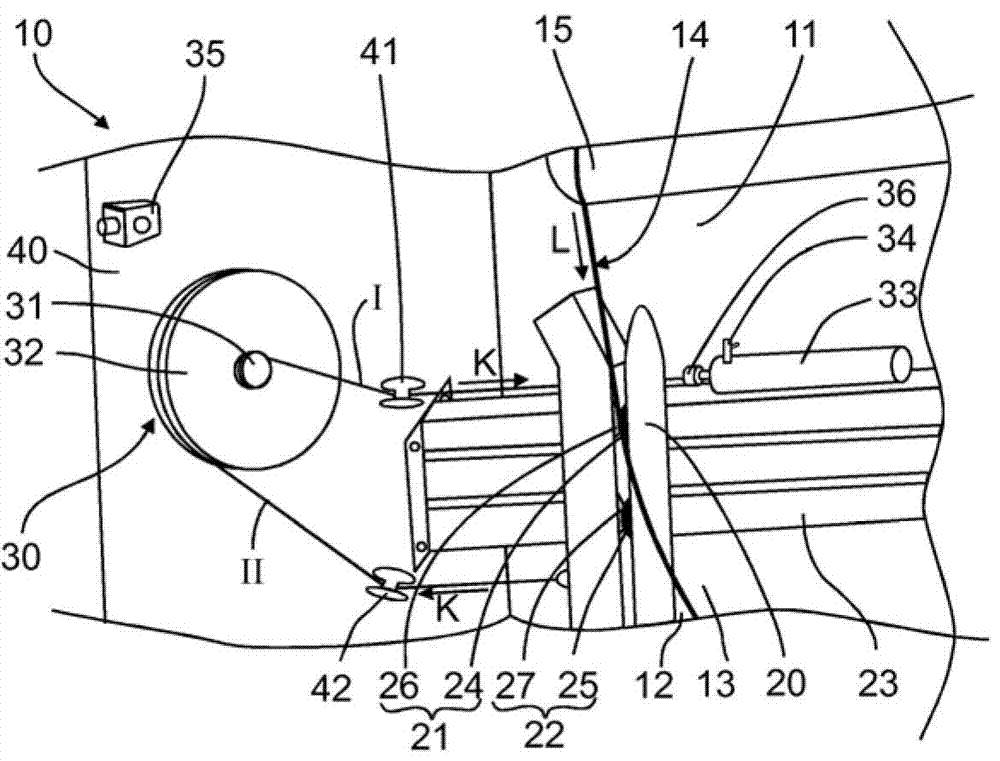

[0054] figure 1 A device for splitting the tubular web 11 into two flat webs 12, 13 is shown, as is known in the prior art. The device is equipped with an adjustable knife 20 which is aimed at the folded edge 14 of the tubular web 11 . The knife 20 is movable along a guide rail 23 which extends perpendicularly to the direction of travel of the tubular web 11 . As the tubular web 11 becomes wider, the knife 20 is moved to the left. As the tubular web 11 becomes narrower, the knife 20 is moved to the right in order to hit the fold 14 . to this end, figure 1 The device in is only designed so that the knife 20 is loaded towards the left in the view relative to the tubular web 11 towards the outside. The device here has a pulling device 30 with a rope drum and a pulling rope I which is guided to the knife 20 via guide rollers 41 . Pull cord 1 keeps tension all the time and knife 20 is pressed to the left. However, there is the disadvantage that when unwinding and rewinding th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com