A finished product unloading mechanism of a packaging bag nozzle welding machine

A technology of unloading mechanism and welding nozzle machine, applied in packaging and other directions, can solve the problem of unsuitable unloading mechanism, etc., and achieve the effect of improving the level of production automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

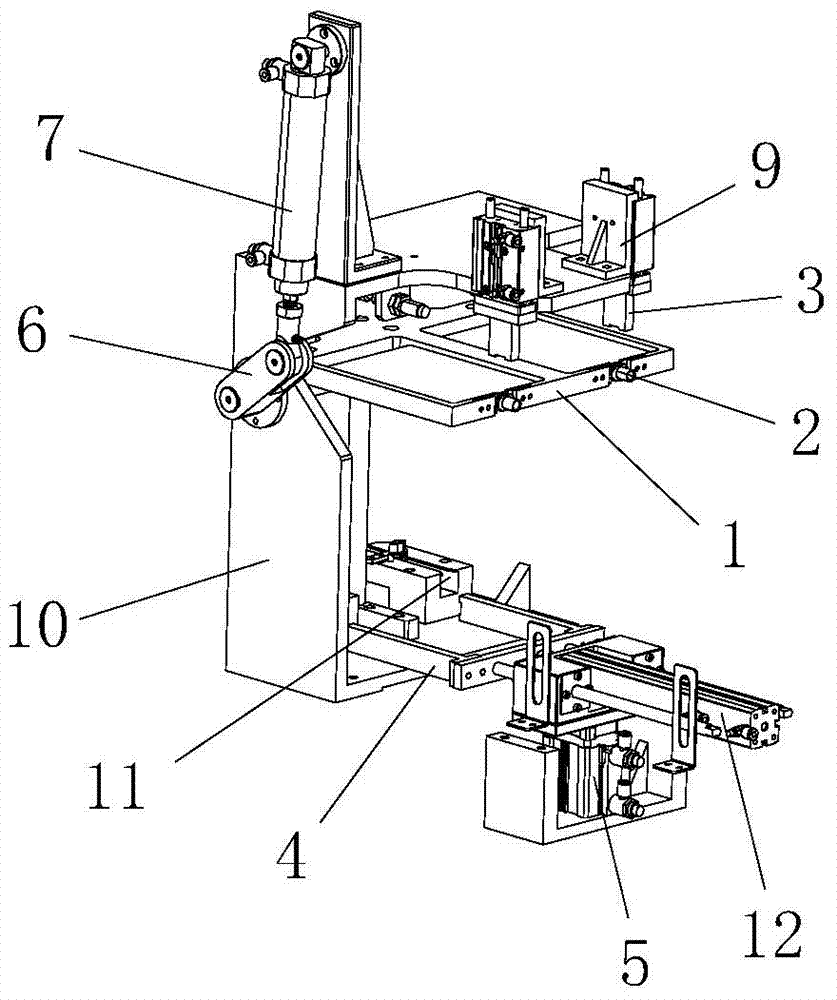

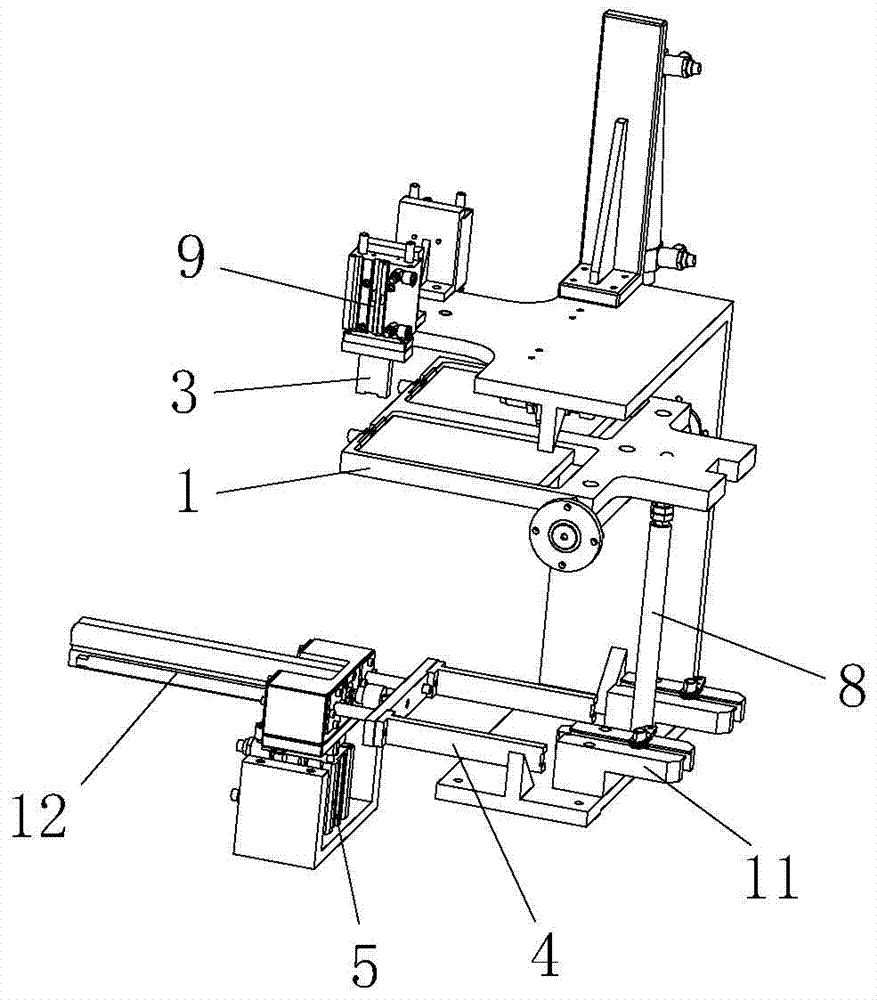

[0011] Reference Figure 1 to Figure 2 , A finished product discharging mechanism of a packaging bag welding nozzle machine, comprising a discharging bracket 10 and a rotating splice plate 1, one side of the rotating splice plate 1 is hinged on the discharging bracket 10, and the rotating splice The material plate 1 is connected with a turning mechanism; the rotating material receiving plate 1 is provided with a material receiving port 2, and a blanking head 3 that can move up and down is installed above the rotating material receiving plate 1, and the blanking head 3 is driven by an air cylinder 9 Move up and down, when the rotating receiving plate 1 is in a horizontal position, the blanking head 3 is facing the receiving port 2, and under the rotating receiving plate 1 through the discharge lifting cylinder 5 is installed front and rear The moving discharge head 4 moves back and forth under the drive of the air cylinder 12. When the rotating receiving plate 1 is in a vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com