Automatic goods collecting trolley driven by potential energy

An automatic and small car technology, applied in the field of engineering applications, can solve the problems of low cost, laborious labor, energy shortage, etc., and achieve the effect of reasonable structure design, stable operation and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

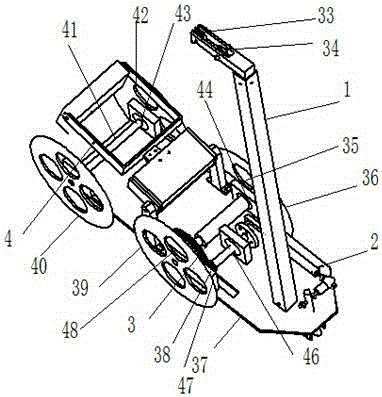

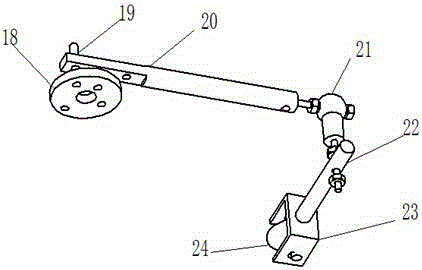

[0025] Example 1: as Figure 1-6 As shown, an automatic pickup trolley driven by potential energy includes a support mechanism 1, a steering mechanism 2, a transmission mechanism 3, and an automatic pickup mechanism 4; On the bottom plate 37 of 3, the steering mechanism 2 is connected with the driving shaft 11 of the transmission mechanism 3 through the turntable 18, the transmission mechanism 3 is fixed on the bottom plate 37 through the bearing seat, and the automatic pickup mechanism 4 is connected with the vertical support frame I25 and the vertical support frame II32. The bottom plate 37 of the transmission mechanism 3 is fixed.

Embodiment 2

[0026] Example 2: as Figure 1-6 As shown, an automatic pickup trolley driven by potential energy includes a support mechanism 1, a steering mechanism 2, a transmission mechanism 3, and an automatic pickup mechanism 4; On the bottom plate 37 of 3, the steering mechanism 2 is connected to the driving shaft 11 of the transmission mechanism 3 through the turntable 18, the transmission mechanism 3 is fixed on the bottom plate 37 through the bearing seat, and the automatic pickup mechanism 4 is connected with the vertical support frame I25 and the vertical support frame II32. The bottom plate 37 of the transmission mechanism 3 is fixed.

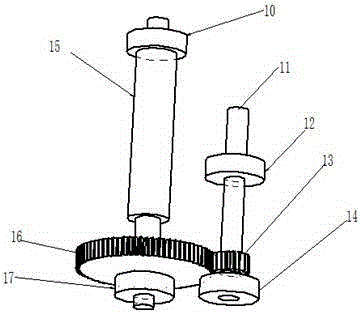

[0027] The support mechanism 1 includes an axis I5, an axis II6, a horizontal bracket 7, a support rod 8, a base 9, a fixed pulley I33, and a fixed pulley II34; , shaft II6 are connected with the horizontal bracket 7, the horizontal bracket 7 is connected with the support rod 8, the support rod 8 is connected with the base 9, and the base 9 is in...

Embodiment 3

[0028] Example 3: as Figure 1-6 As shown, an automatic pickup trolley driven by potential energy includes a support mechanism 1, a steering mechanism 2, a transmission mechanism 3, and an automatic pickup mechanism 4; On the bottom plate 37 of 3, the steering mechanism 2 is connected to the driving shaft 11 of the transmission mechanism 3 through the turntable 18, the transmission mechanism 3 is fixed on the bottom plate 37 through the bearing seat, and the automatic pickup mechanism 4 is connected with the vertical support frame I25 and the vertical support frame II32. The bottom plate 37 of the transmission mechanism 3 is fixed.

[0029] The support mechanism 1 includes an axis I5, an axis II6, a horizontal bracket 7, a support rod 8, a base 9, a fixed pulley I33, and a fixed pulley II34; , shaft II6 are connected with the horizontal bracket 7, the horizontal bracket 7 is connected with the support rod 8, the support rod 8 is connected with the base 9, and the base 9 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com