Cutter for lawn ventilator

A technology of ventilator and cutting tool, which is applied in lawn treatment machinery, agricultural machinery and implements, etc. It can solve the problems of gearbox damage, lithium battery pack damage, impact lithium battery pack, etc., so as to improve the service life and prolong the service life , Improve the effect of impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

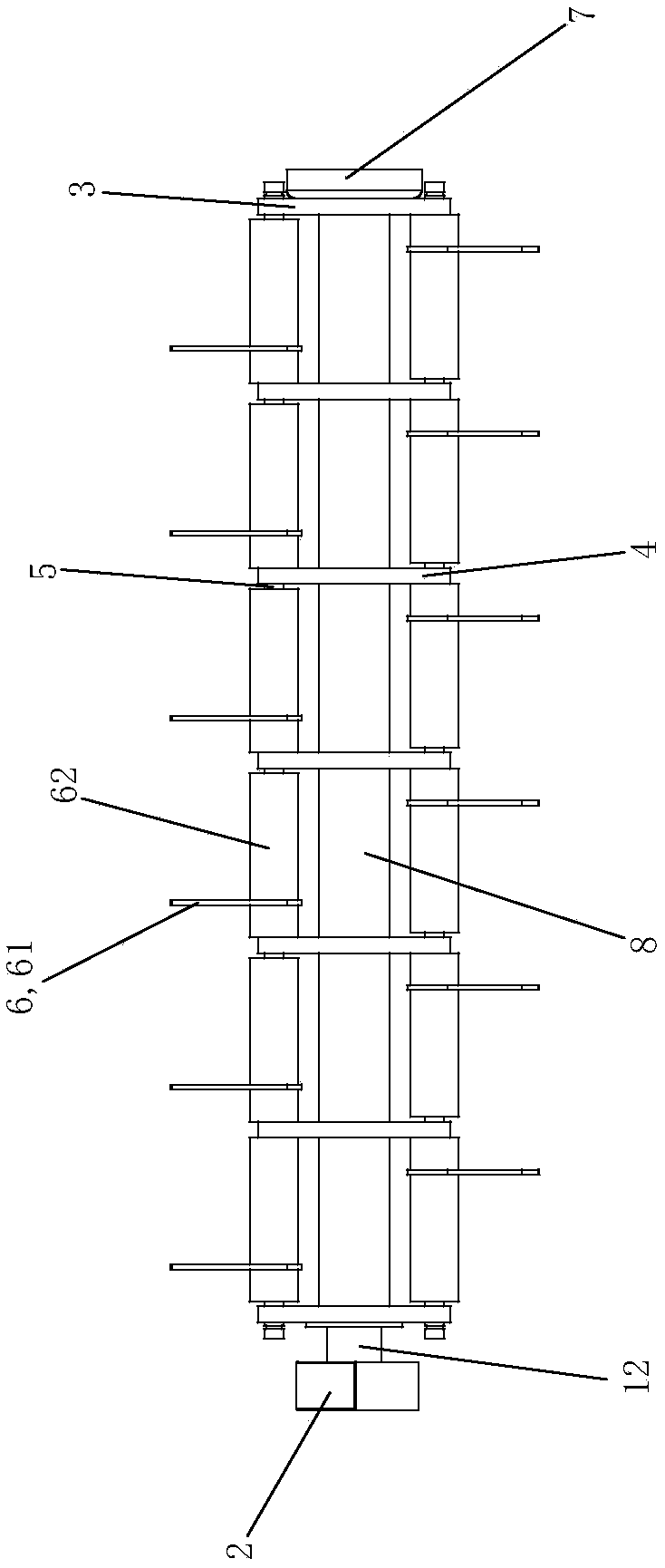

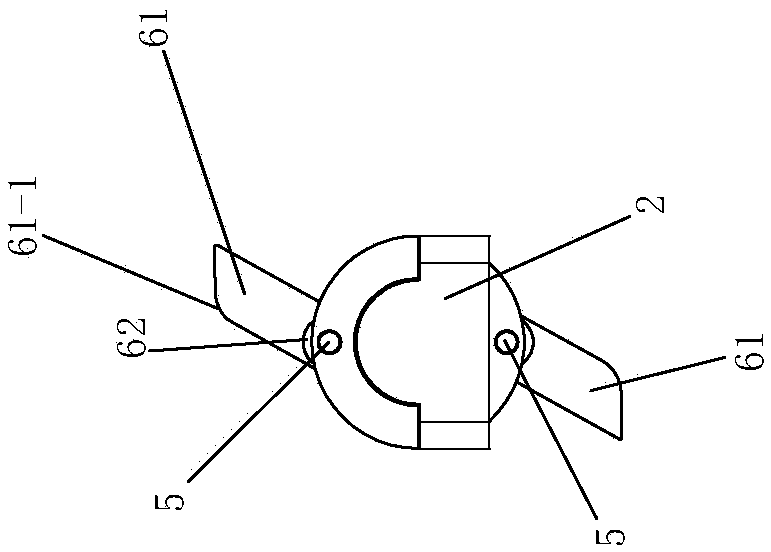

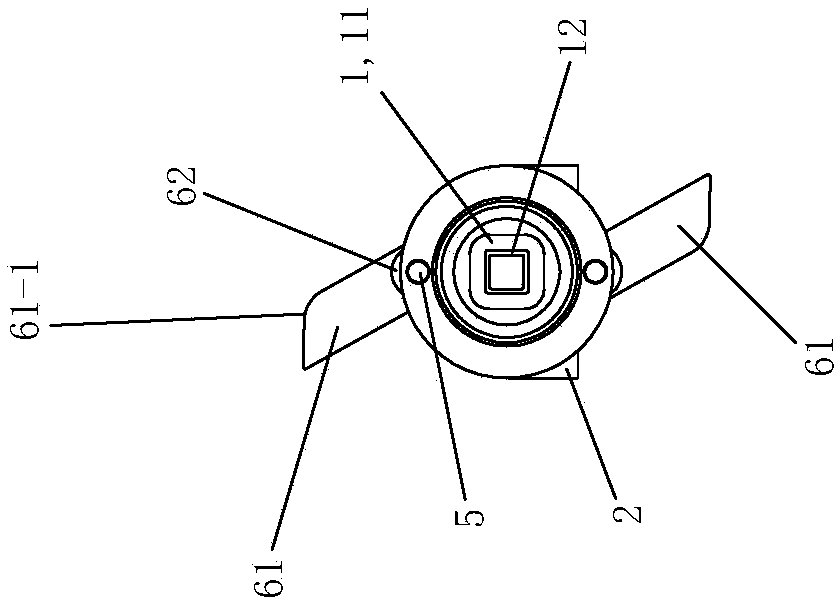

[0040] see Figure 1 to Figure 10 The cutter for a lawn ventilation machine of this embodiment includes a rotating shaft 1, a foot bracket 2, a mounting disk 3, a supporting disk 4, a cutter shaft 5, a blade assembly 6 and a dust cover 7.

[0041] see Figure 1 to Figure 6 The rotating shaft 1 is formed by connecting the long shaft 11 of the square tube and the short shaft 12 which is connected to the left end of the long shaft 11 of the square tube. When in use, the square output shaft of the gearbox of the grass ventilating machine is inserted into the right end of the long shaft 11 of the square tube, and the two are connected in a profile and form a detachable transmission connection for clearance fit. The left end of the stub shaft 12 is rotatably arranged in the foot bracket 2 through a corresponding bearing. The dust cover 7 is fixedly arranged on the right end of the long shaft 11 of the square tube, with the opening to the right, and is used to cover the corresponding p...

Embodiment 2)

[0047] see Picture 11 with Picture 12 The remaining parts of this embodiment are the same as the embodiment 1, and the difference is that: there are 11 support plates 4, and the 11 support plates 4 divide the long axis 11 of the square tube into 12 equal parts. There are 4 cutter shafts 5. The four cutter shafts are arranged at equal intervals along the circumferential direction of the long axis 11 of the square tube. Each section of each cutter shaft 5 is provided with blade assemblies 6 at intervals, and each cutter shaft 5 is provided with 3 sets of blade assemblies 6. The blades 61 on the four cutter shafts 5 are spiral in the axial direction of the long shaft 11 of the square tube Set up.

Embodiment 3)

[0049] The rest of this embodiment is the same as the embodiment 1, the difference is that: there are 15 support plates 4, and the 15 support plates 4 divide the long axis 11 of the square tube into 16 equal parts. There are 8 cutter shafts 5. The eight cutter shafts are arranged at equal intervals along the circumferential direction of the long axis 11 of the square tube. Each section of each cutter shaft 5 is provided with blade assemblies 6 at intervals, and each cutter shaft 5 is provided with 2 sets of blade assemblies 6. The blades 61 on the eight cutter shafts 5 are spiral in the axial direction of the long shaft 11 of the square tube Set up.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com