Patents

Literature

73results about How to "Avoid contamination damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

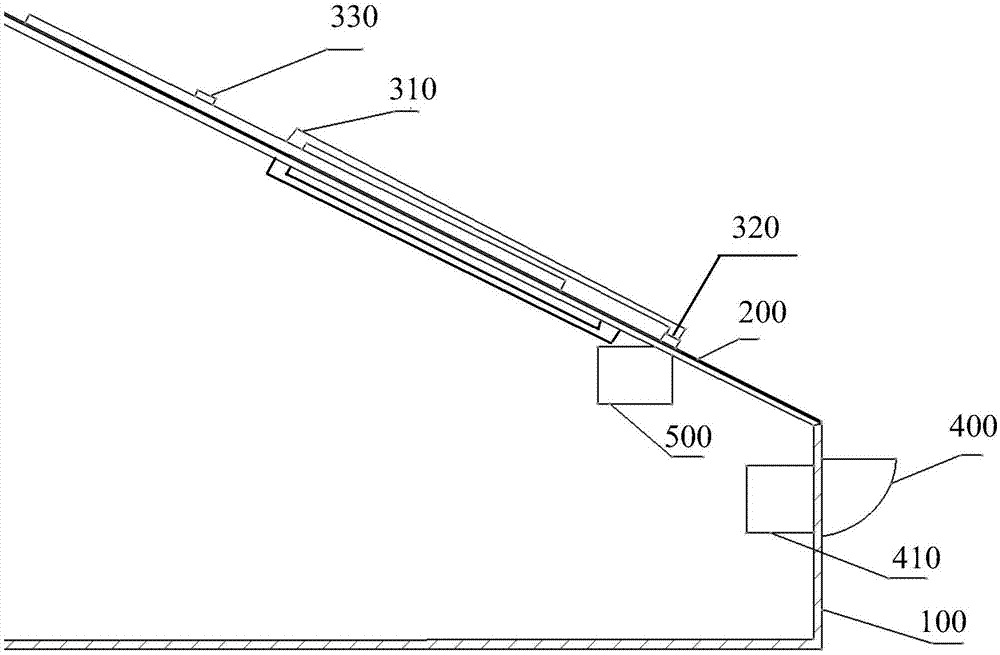

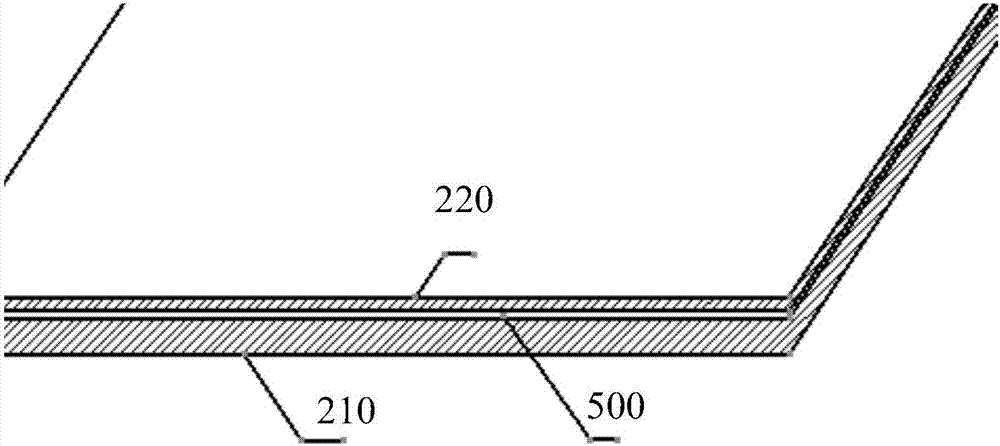

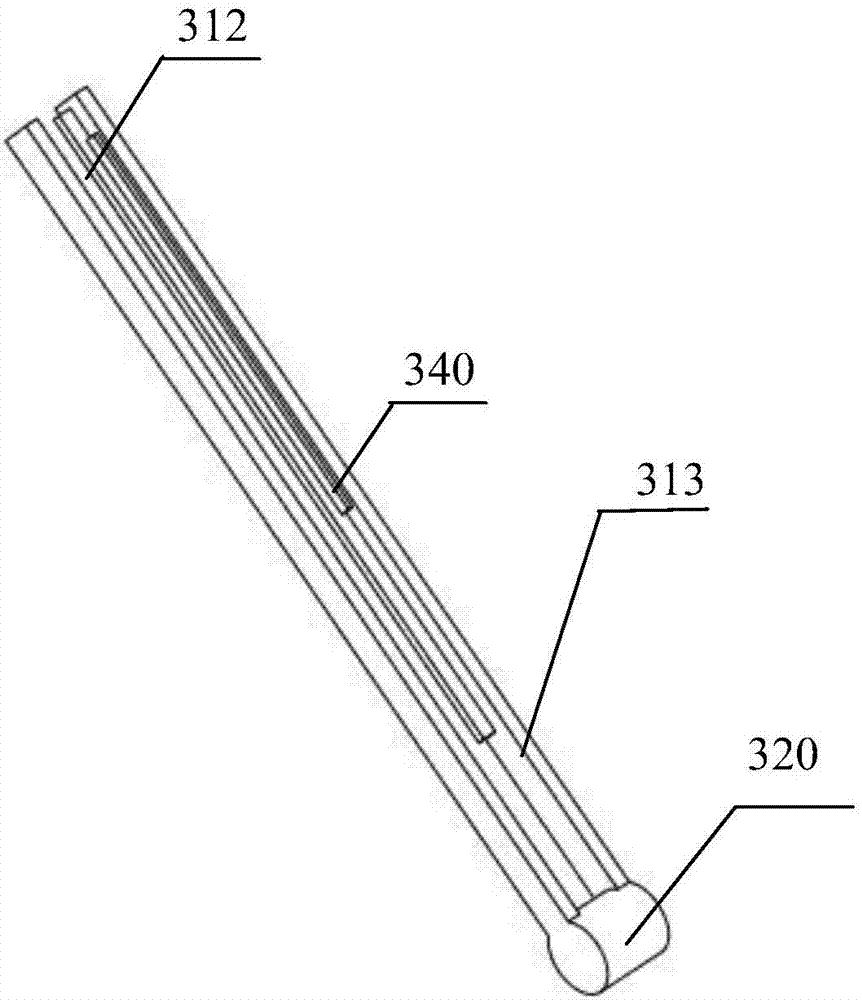

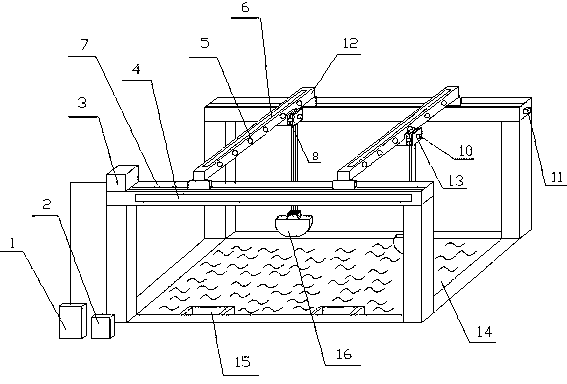

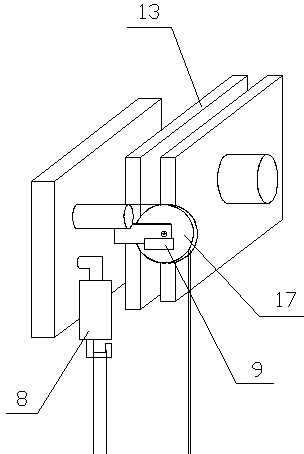

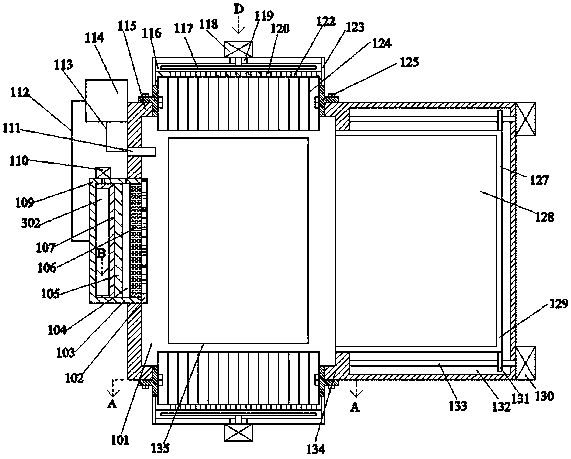

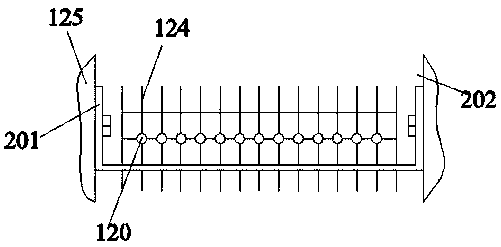

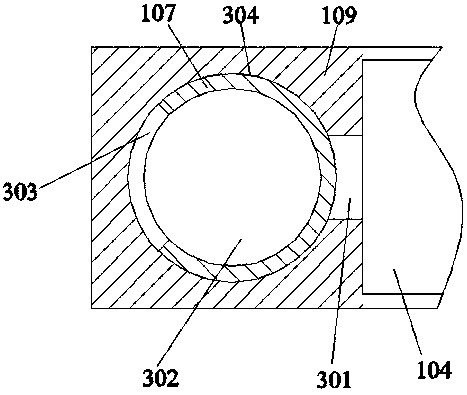

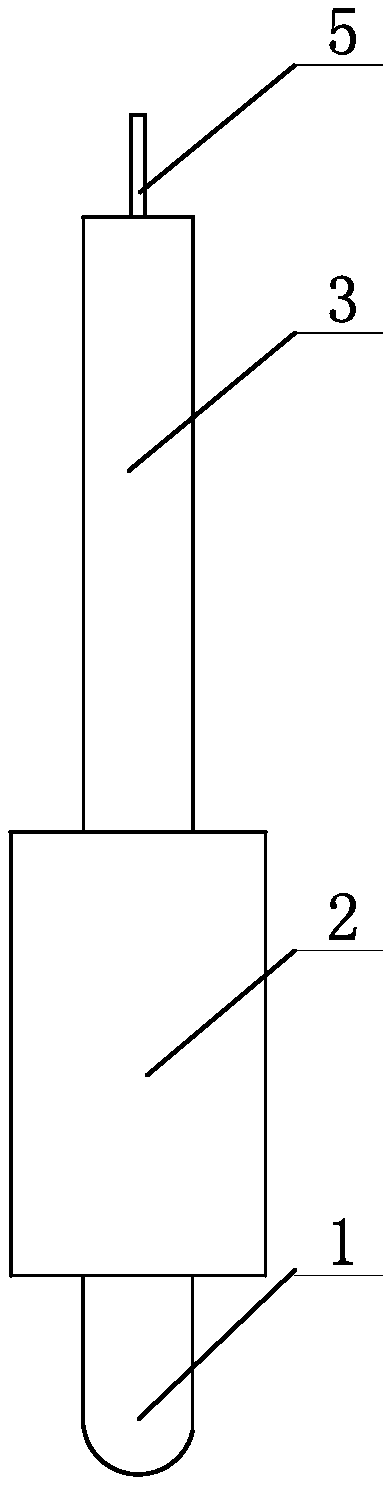

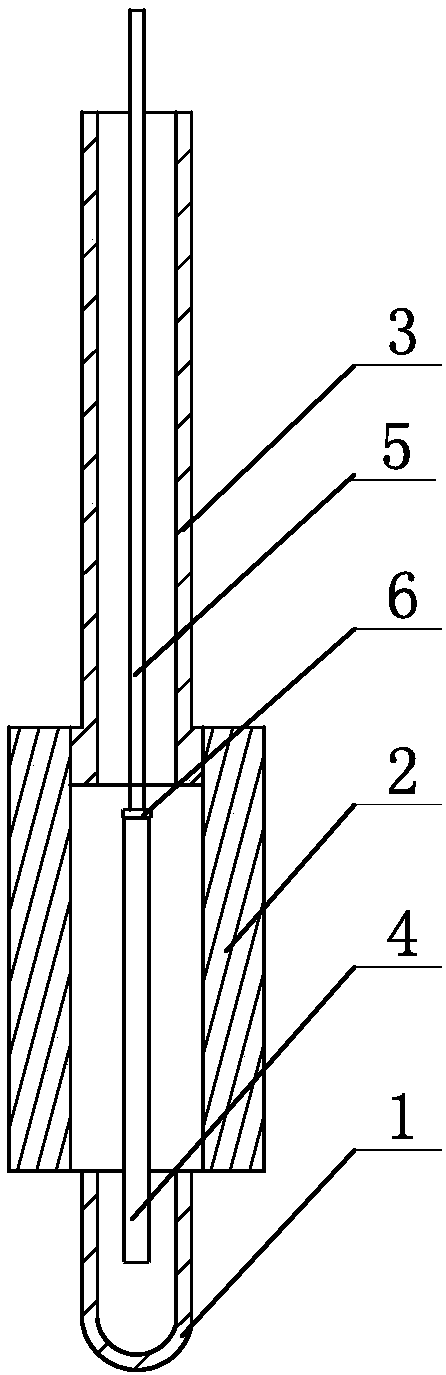

Wind tunnel test device of windscreen wiper pressing force distribution and windscreen wiper controlling method

PendingCN107131995AAvoid wastingAvoid contamination damageAerodynamic testingFluid pressure measurement using ohmic-resistance variationAir velocityWater spray

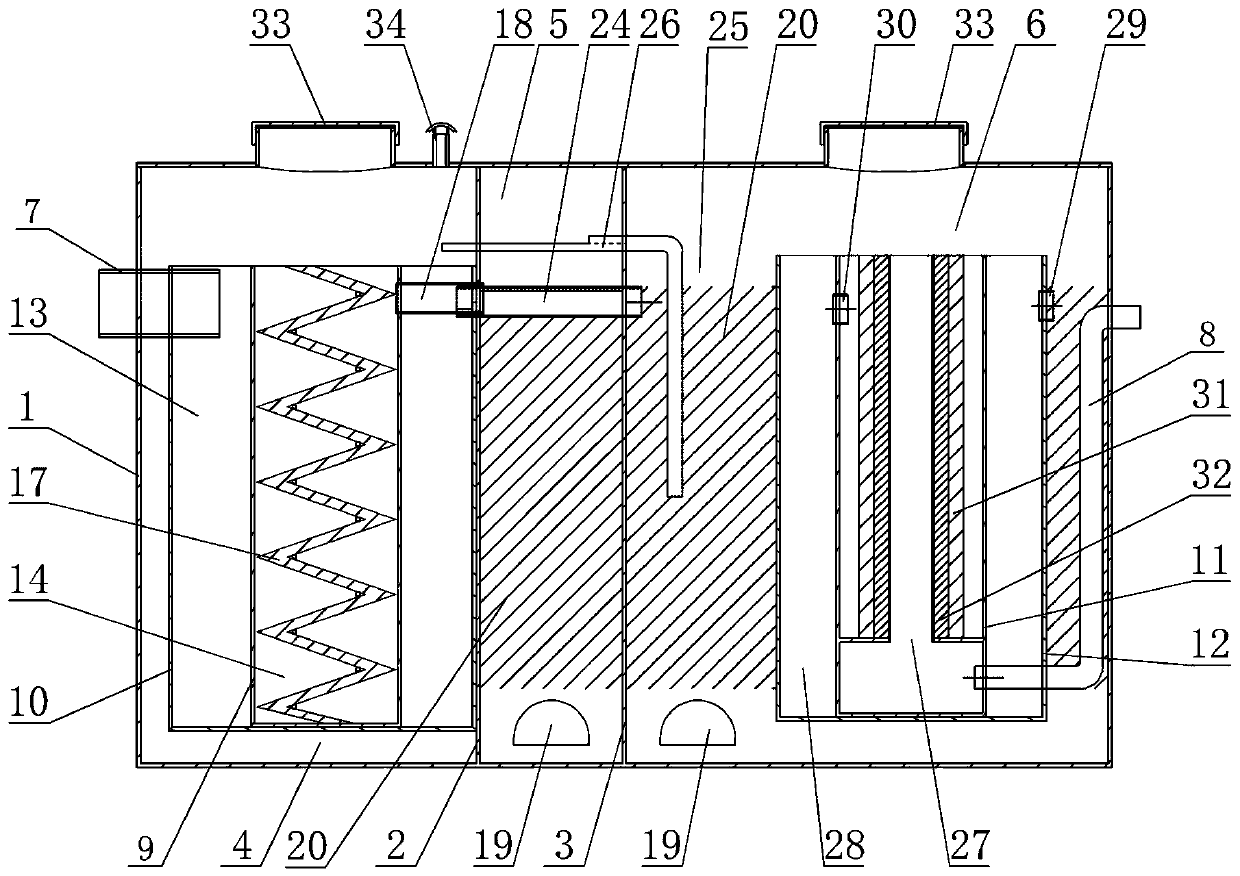

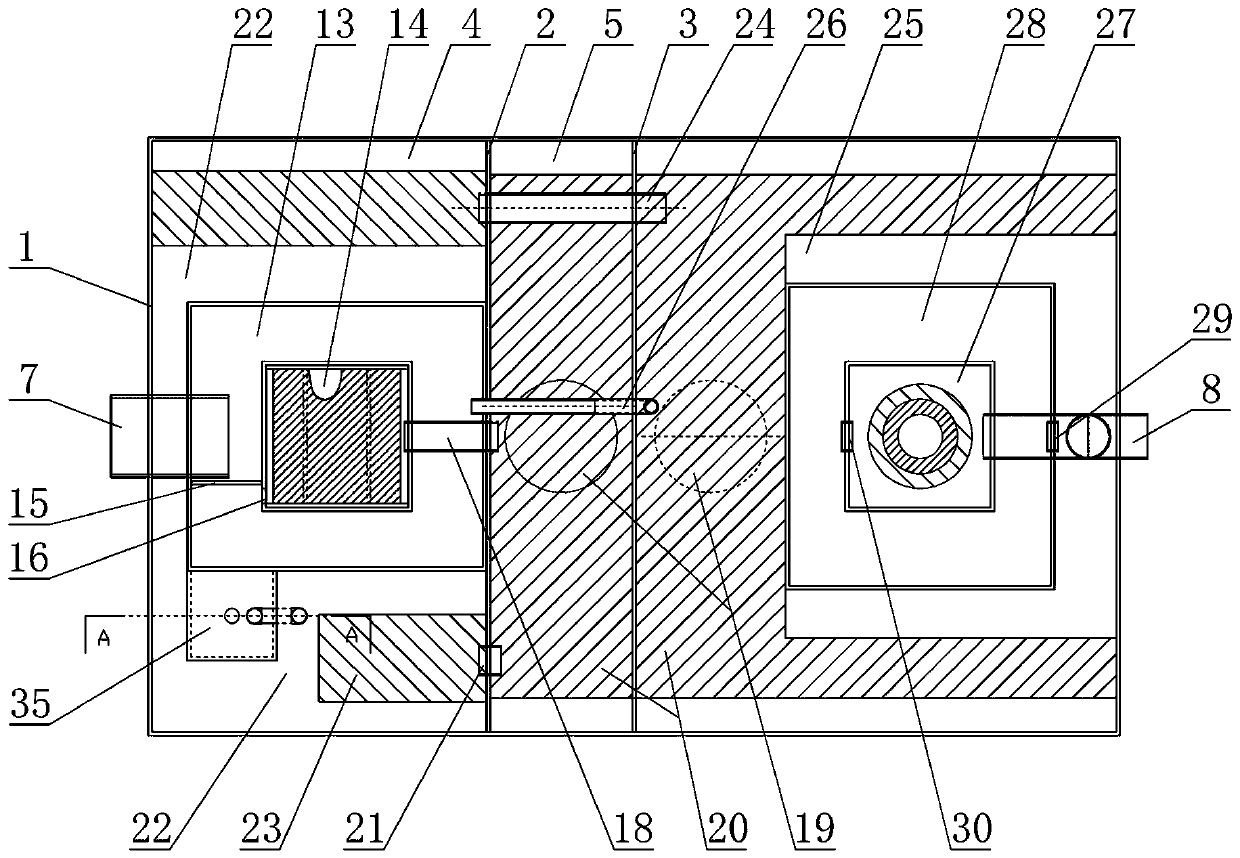

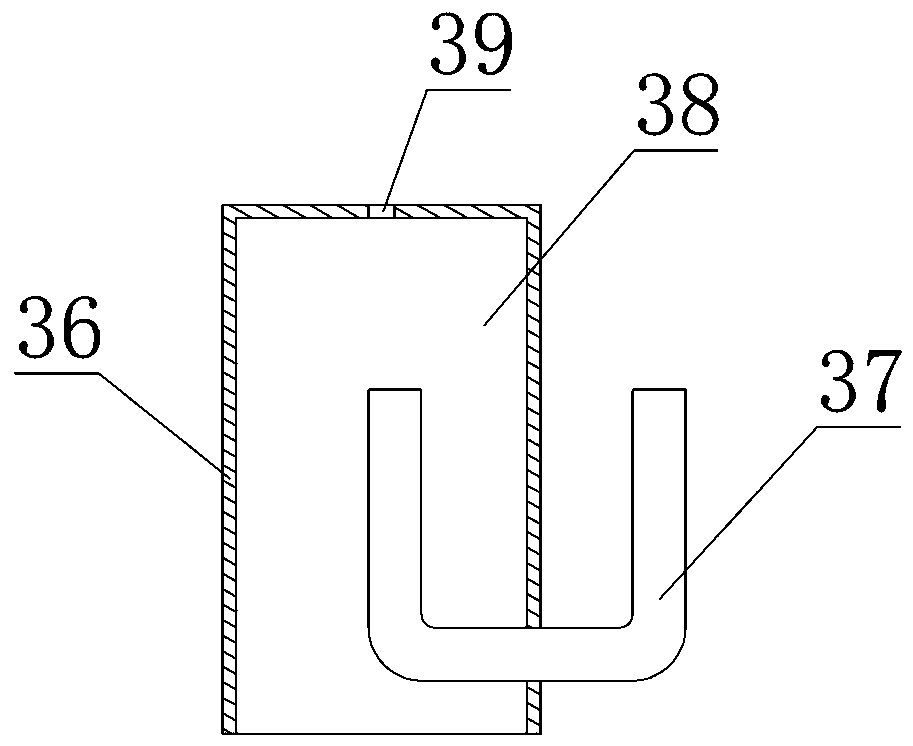

The invention discloses a wind tunnel test device of windscreen wiper pressing force distribution. The device comprises a supporting frame, laminated glass, a windscreen wiper, a rotary shaft, a water spraying nozzle, a water tank and a sensor array, wherein the laminated glass comprises an outer glass thin layer and an inner glass layer; the windscreen wiper is arranged on the outer side of the laminated glass and comprises a windscreen wiper arm, and the windscreen wiper arm is arranged on the surface of the outer glass thin layer in an attached mode; the rotary shaft is arranged at one end of the windscreen wiper arm, and the windscreen wiper arm can rotate around the rotary shaft; the water spraying nozzle is arranged at the other end of the windscreen wiper arm; the water tank is arranged at the lower end of the device and connected with the water spraying nozzle through a water pump; the sensor array is arranged between the outer glass thin layer and the inner glass layer. The technical purpose is to provide a wind tunnel test device of windscreen wiper pressing force distribution. According to the pressure of different scraping areas, the state of the windscreen wiper pressing force distribution and the change rule of windscreen wiper pressing force with wind speed are obtained, and a reference is provided for design and improvement of the windscreen wiper; a windscreen wiper controlling method is also provided, the change rule of the windscreen wiper pressing force with vehicle speed is measured based on the wind tunnel test of the windscreen wiper, and the pressing force of the windscreen wiper arm is adjusted through the magnitude of a current, so that a better scraping effect is obtained.

Owner:JILIN UNIV

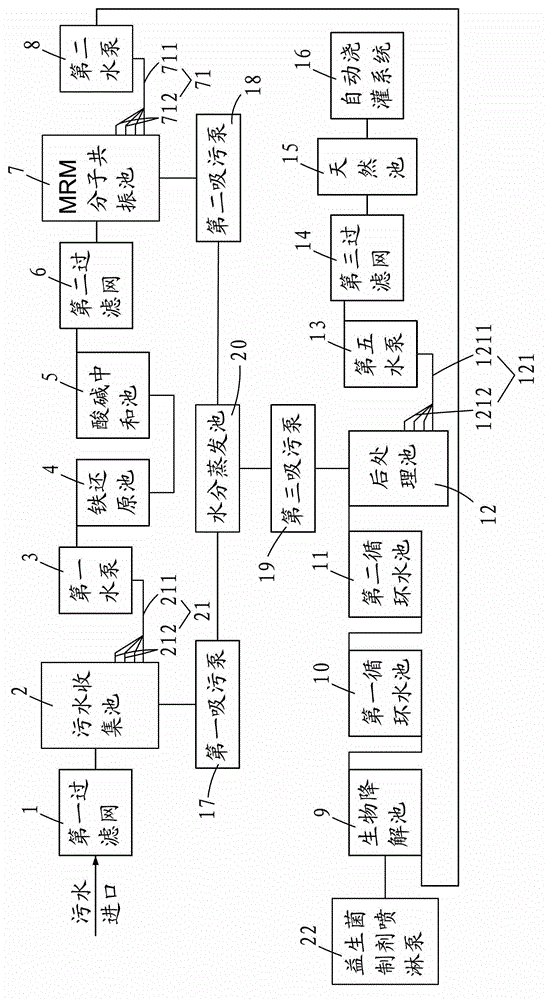

Sewage treatment method

ActiveCN102745862ACause secondary pollutionAvoid contamination damageWater/sewage treatment with mechanical oscillationsEnergy based wastewater treatmentIron reductionHeavy metals

The invention provides a sewage treatment method. The sewage treatment method comprises the following steps of filtering sewage by a first filter screen, reducing the filtered sewage by an iron reduction tank, carrying out acid-base neutralization by an acid-base neutralization tank, carrying out MRM molecular resonance, carrying out biodegradation purification, and standing for 24 hours in an after-treatment tank. The sewage treatment method realizes zero discharge of sewage. The sewage treatment method has a low cost, can be operated simply, does not adopt any chemical reagents in after-treatment, does not produce secondary pollution on the environment, and solves the problem that heavy metals and microbes in specialized laboratory sewage produced by the existing scientific research institutions and hospitals pollute and damage the environment.

Owner:张明荣

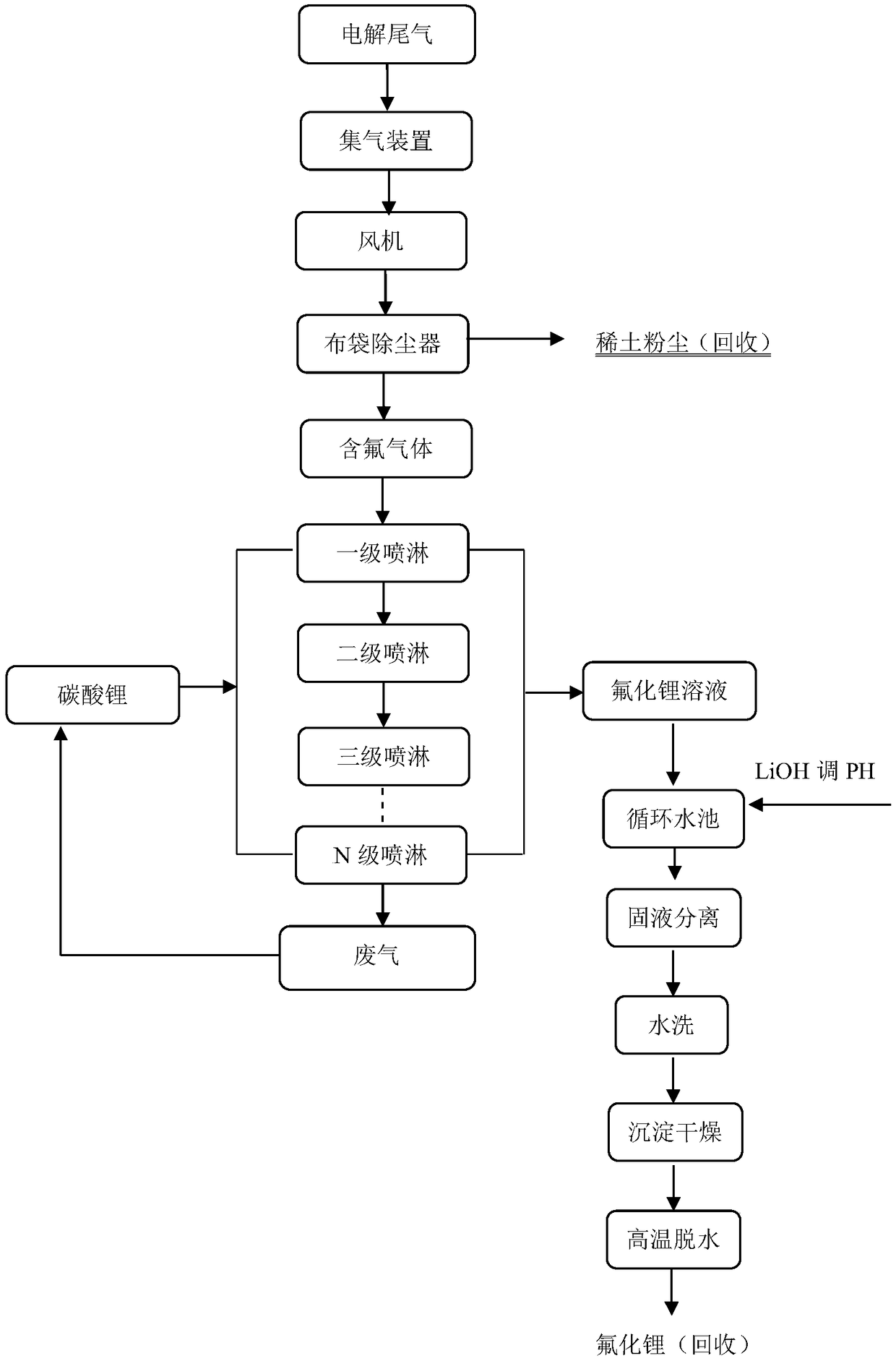

Method for recycling waste gas generated by rare earth electrolyzed by fluoride system

ActiveCN108654347AImprove solubilityImprove adsorption capacityDispersed particle filtrationSolubilityElectrolysis

The invention discloses a method for recycling waste gas generated by rare earth electrolyzed by a fluoride system. The method includes the steps: treating the waste gas generated by electrolysis by adust removal device, leading in lithium hydrogen carbonate serving as absorbing agents to perform chemical absorption on a spray absorption tower, directly leading the chemically absorbed waste gas with carbon dioxide serving as a main component in a lithium carbonate liquid tank, converting lithium carbonate into the lithium hydrogen carbonate with high solubility, injecting the lithium hydrogencarbonate into the spray absorption tower to be recycled, and continuing to capture fluorine ions in fluorine-containing gas; performing solid-liquid separation, washing, drying and high-temperaturedehydration on a new substance generated after spraying absorption to obtain lithium fluoride for electrolyzing rare earth. According to the method, rare earth dust and fluorine-containing tail gas are firstly separated, the lithium hydrogen carbonate serves as a capturing agent of the fluorine ions, the comprehensive yield can reach 84.50% or more, the comprehensive yield of a system reaches 96%or more after reaction is completely balanced, carbon dioxide in the absorbed waste gas serves as a raw material to be directly led into the lithium carbonate liquid tank to circularly prepare a lithium hydrogen carbonate absorbing agent, and emission of the carbon dioxide is greatly reduced.

Owner:山东南稀金石新材料有限公司

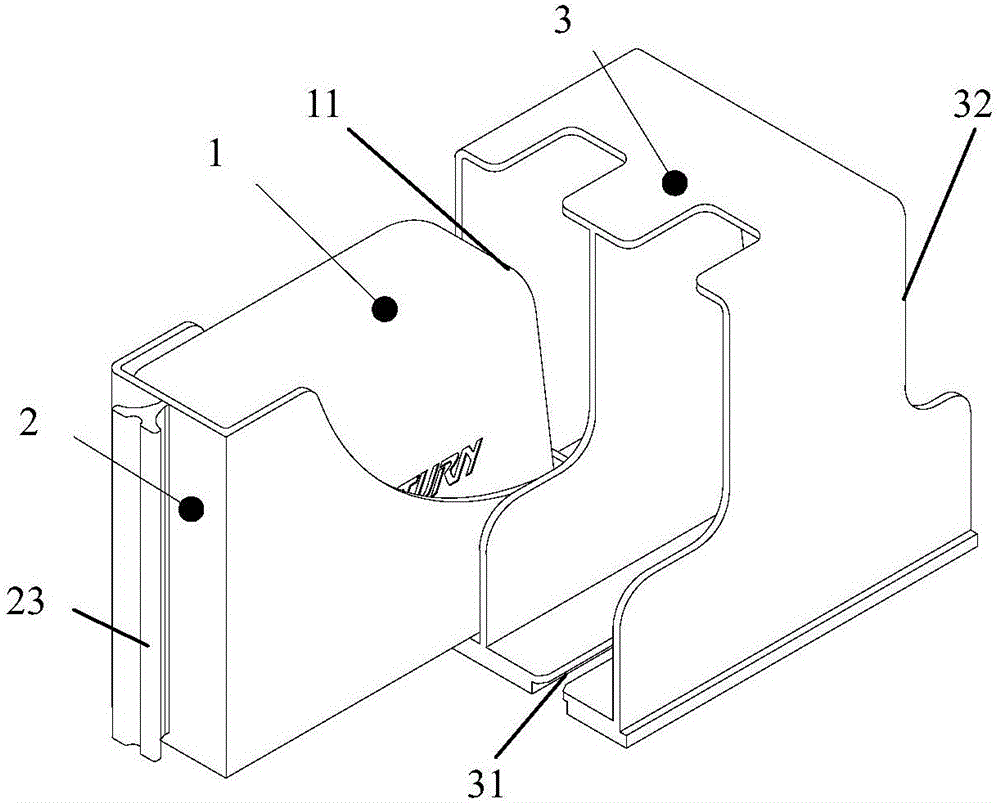

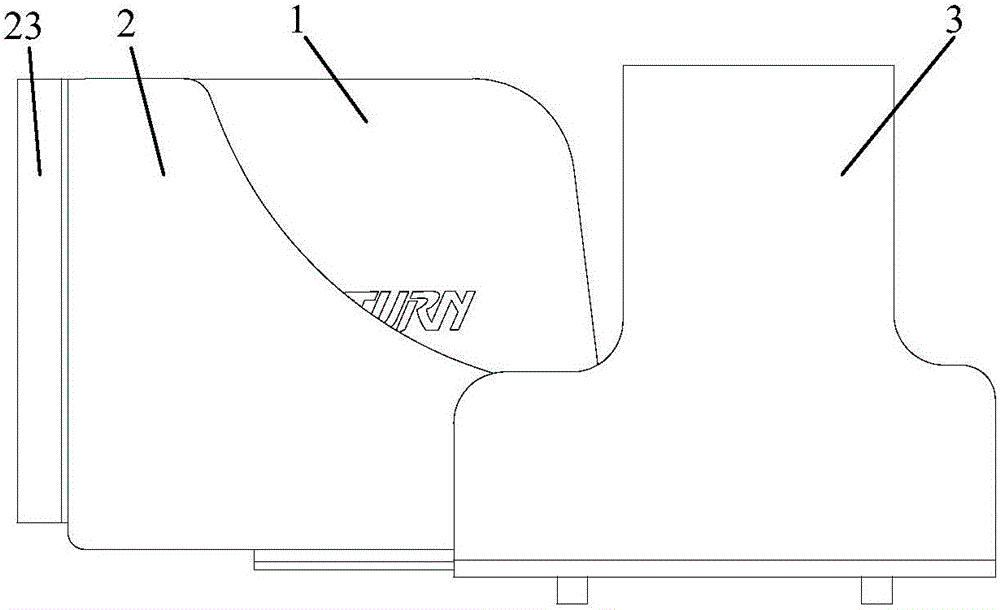

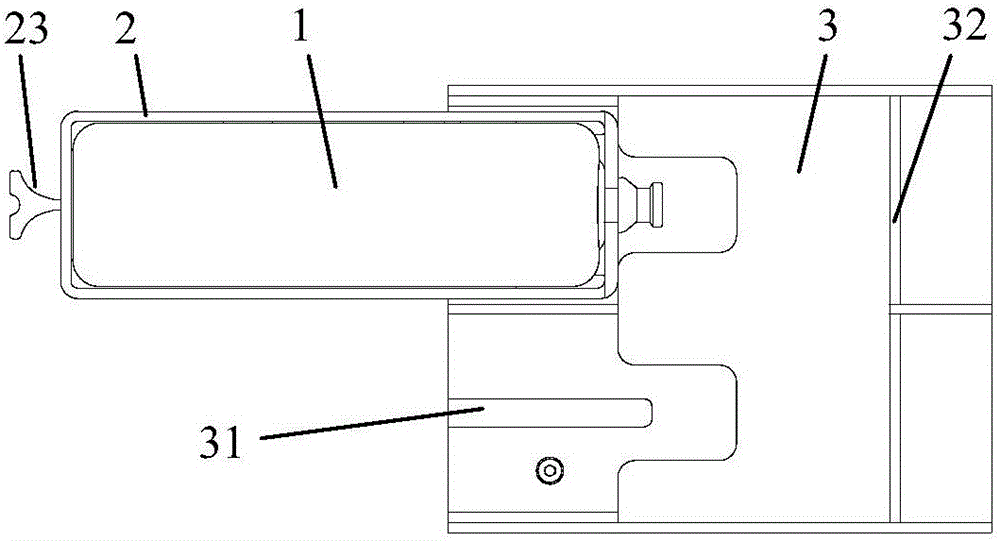

Ink cartridge device for ink-jet printer

The invention provides an ink cartridge device for an ink-jet printer, which comprises a consumable material bottle, a shell and a base, and is characterized in that the internal part of the consumable material bottle is provided with an inner cavity; the internal part of the shell is provided with an accommodating cavity, the upper part of the shell is provided with an opening, and the consumable material bottle is inserted in or pulled out from the accommodating cavity through the opening; and the base is provided with at least one slot, and the shell can be in sliding connection with the base and can slide into or out of the slot. The ink cartridge device further has a function of encryption with the encryption mode being RFID smart tag encryption so as to be used for reading the type and the available time of a consumable material. The ink cartridge device for the ink-jet printer only needs to replace the consumable material bottle after the consumable material is used up, the shell is not required to be replaced, and the consumable material bottle is installed and replaced conveniently and efficiently. Meanwhile, manufacturer information of the used consumable material can be read accurately and effectively, and the service time of the consumable material is monitored in real time.

Owner:北京赛腾标识系统股份公司

Rural sewage treatment device and method

PendingCN109761457AReasonable structure layoutImplement filteringWater contaminantsMultistage water/sewage treatmentWater sourceFiltration

The invention relates to a rural sewage treatment device and method. Two partition plates in a tank body divide the tank body into a first grid groove, a second grid groove and a third grid groove, wherein the first grid groove is divided into a sedimentation tank, a first filtration tank and an anaerobic area; the second grid groove is divided into a first aerobic area; the third grid groove is divided into a second aerobic area, a phosphorus-removing tank and a second filtration tank; sewage settles firstly in the sedimentation tank and is filtered in the first filtration tank, and then theremoval of COD, ammonia nitrogen and organic phosphorus in sewage is realized by the first aerobic area; then, the sewage is subjected to deamination treatment in the anaerobic area, afterwards, the COD and a redundant carbon source are removed in the second aerobic area, phosphorus in the sewage is removed by the phosphorus-removing tank, finally, the sewage is filtered by the second filtration tank and then discharged, the successive settling, filtering, aerobic, anaerobic, aerobic, phosphorus-moving and filtering treatments of the sewage are realized, which guarantees that rural domestic sewage is connverted into a qualified water source and discharged, and the pollution and damage to surrounding soil environment and air environment are avoided.

Owner:BEIJING UNIV OF TECH

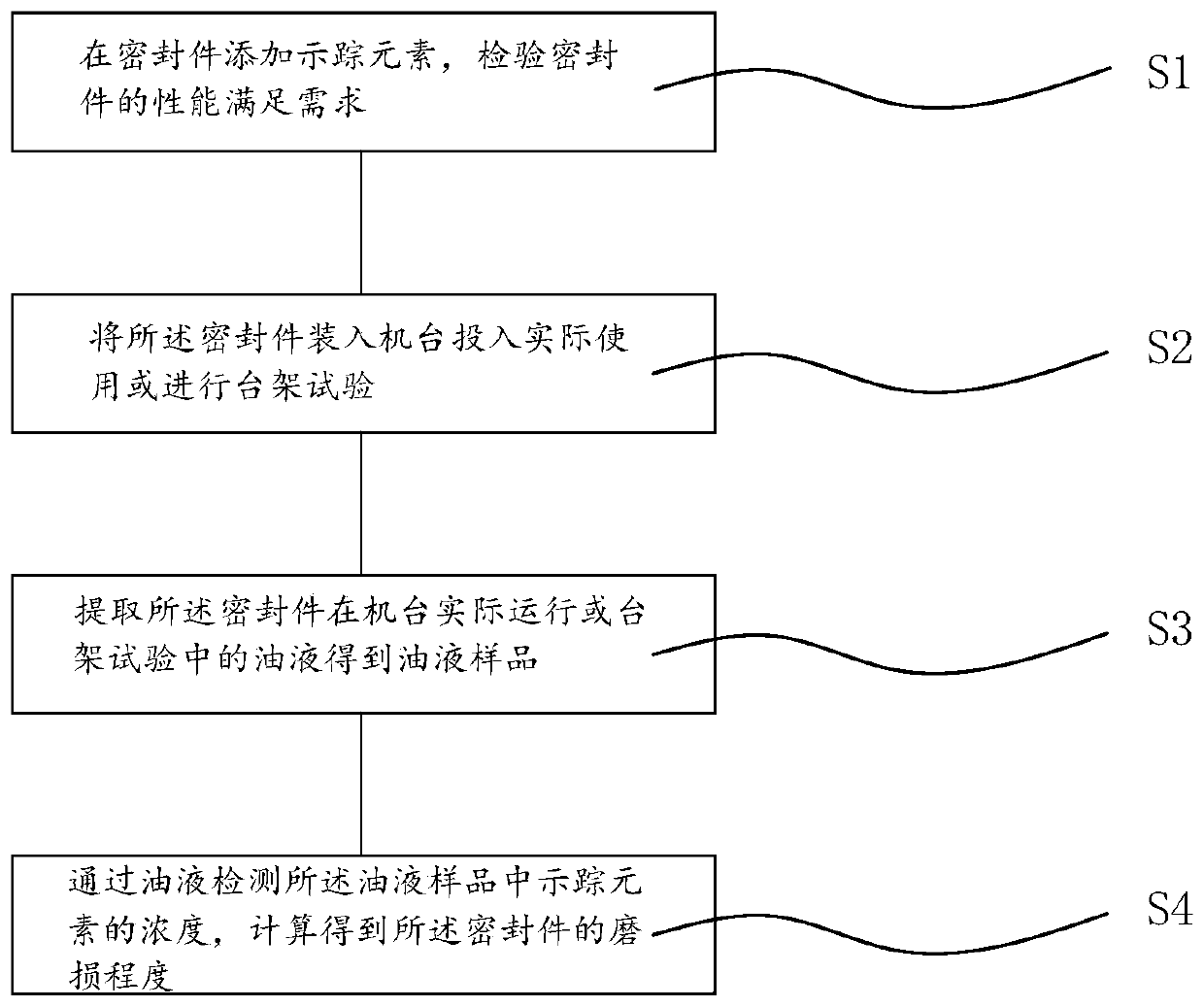

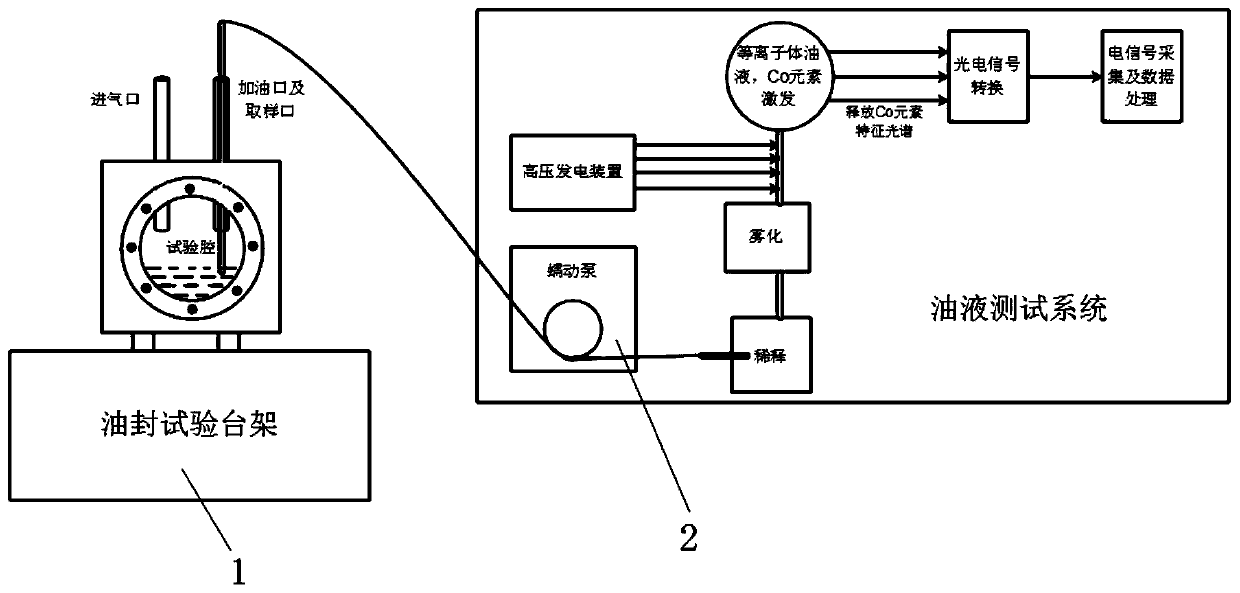

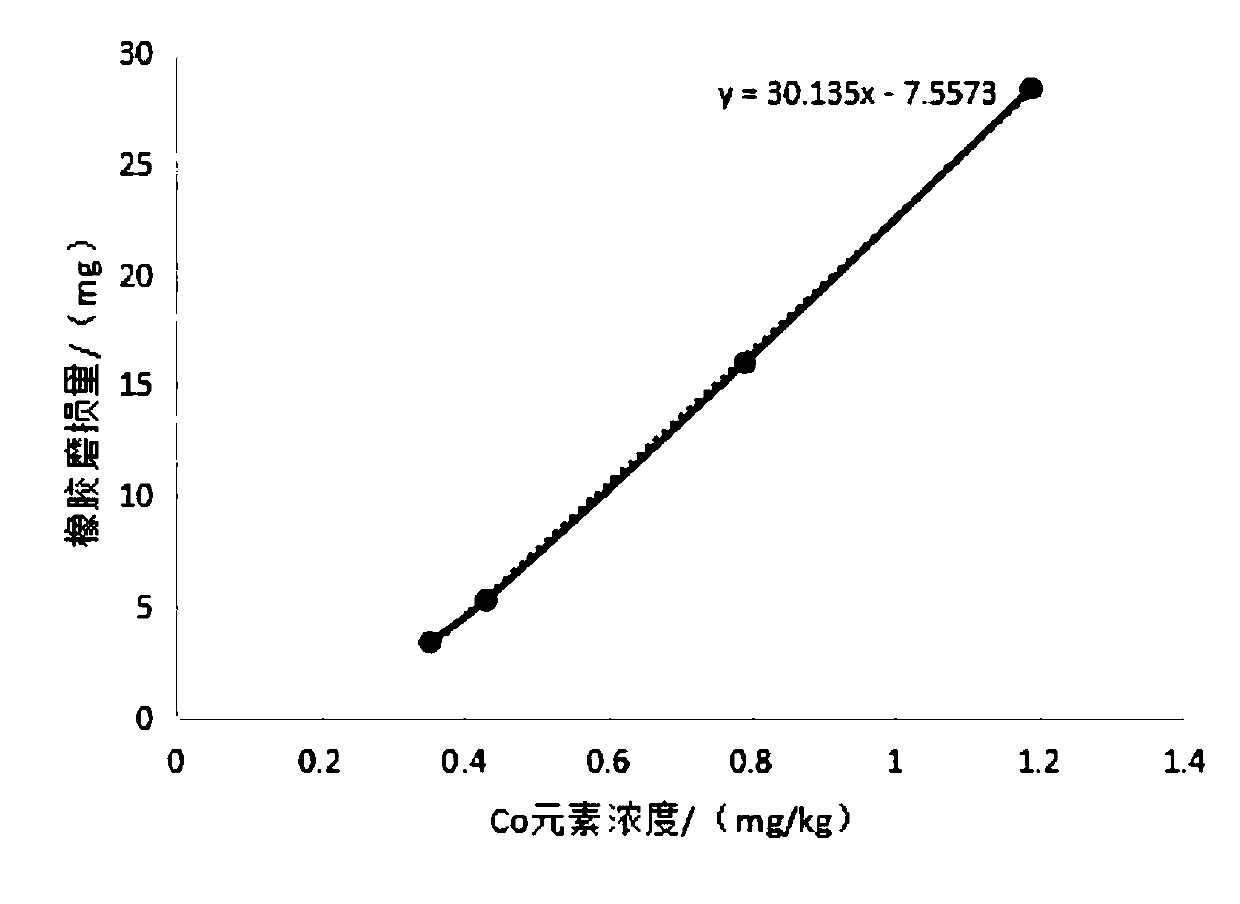

A method for detecting abrasion loss of sealing element

InactiveCN110988108AReal-time monitoring of wear statusNo need to dismantleMaterial analysis by electric/magnetic meansMachine sealing rings testingThermodynamicsTrace element

The invention provides a method for detecting the abrasion loss of a sealing element. The method at least comprises the following steps of adding a tracing element to the sealing element; putting thesealing element into a machine table to be put into actual use or carrying out a bench test; extracting oil liquid of the sealing element in actual operation of a machine table or in a bench test to obtain an oil liquid sample; and detecting the concentration of the tracer element in the oil sample through oil, and calculating to obtain the wear degree of the sealing element. According to the method for detecting the abrasion loss of the sealing element, the abrasion degree of the sealing element is obtained before the sealing element is abraded and loses efficacy, and economic losses and environmental pollution caused by sealing failure of the sealing element are avoided.

Owner:GUANGZHOU MECHANICAL ENG RES INST +1

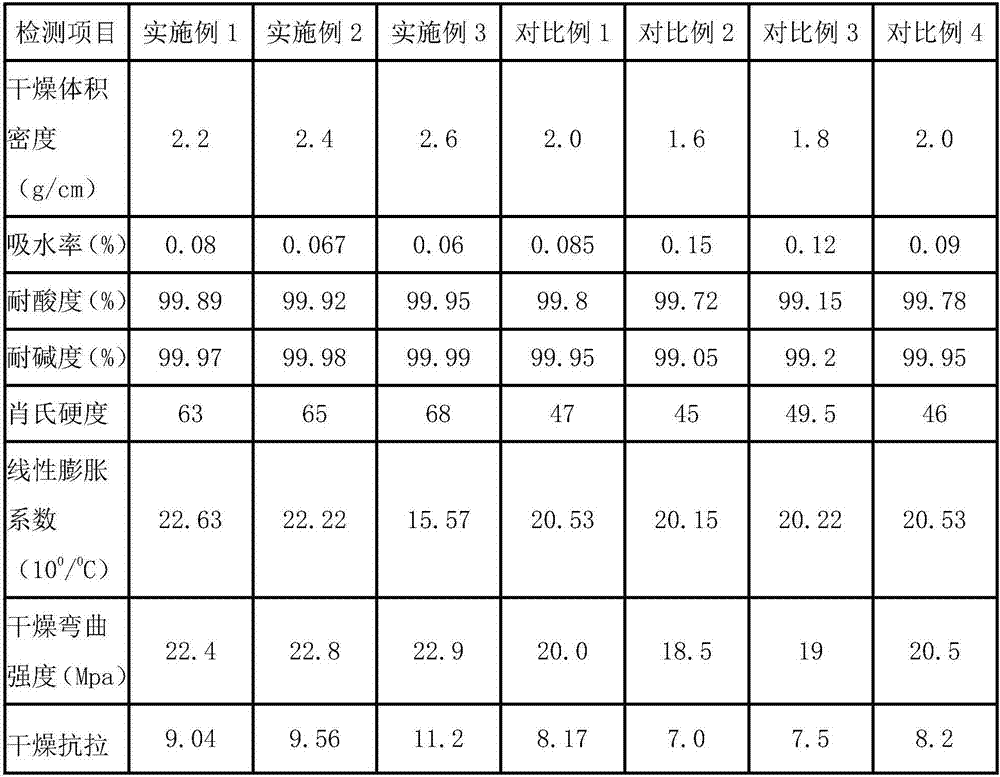

Method for preparing mullite multiphase ceramic by low-temperature sintering of bauxite tailings

The invention discloses a method for preparing mullite multiphase ceramic by low-temperature sintering of bauxite tailings, and belongs to the technical field of high-value utilization of the bauxite tailings and ceramic preparation. According to the invention, bauxite tailings, bauxite clinker and lithium chinastone are adopted as main raw materials, and the mullite multiphase ceramic is prepared through the processes of batching, ball milling, molding and low-temperature sintering. The mullite multiphase ceramic material prepared by low-temperature sintering of the bauxite tailings has the characteristics of high compressive strength, small linear shrinkage rate, high volume density and simple preparation process, and can be used in industries such as high-value utilization of the bauxite tailings and ceramics. The required raw materials are easy to obtain, the preparation process is simple, the utilization amount of the bauxite tailings is high, the problems of massive accumulation of the bauxite tailings and pollution and damage to the environment can be solved, and waste is turned into wealth; and by adding the bauxite tailings, the sintering temperature of the mullite multiphase ceramic can be reduced, the cost and the energy consumption are low, and high-value utilization of the bauxite tailings is realized.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

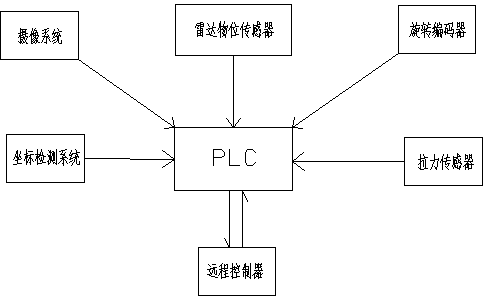

Remote operation control system of overhead traveling crane for delayed coking

ActiveCN103309275AAccurate running controlEasy to detectProgramme control in sequence/logic controllersProgrammable logic controllerRadar

The invention relates to an operation control system of a hydraulic-decoking overhead travelling crane for delayed coking, in particular to a remote operation control system of an overhead travelling crane for delayed coking. The remote operation control system comprises a coordinate detecting system, a camera system, radar material level sensors, rotating encoders, tension sensors and a remote controller. The coordinate detecting system is used for detecting running directions of large cranes and small cranes on the overhead travelling crane. The camera system is used for monitoring operation conditions of the overhead travelling crane. The radar material level sensors are used for scanning a coking pool to acquire stacking thickness information of coke in the coking pool. The rotating encoders are used for detecting displacement of grab buckets of the overhead travelling crane in the vertical direction. The rotating encoders are mounted on pulley blocks of the small cranes. The tension sensors are used for detecting weight of materials grabbed by the grab buckets of the overhead traveling crane. One ends of the tension sensors are fixed on the small cranes while the other ends of the same are connected with steel wire ropes supporting the small cranes. The remote controller is used for remotely controlling operations of the overhead travelling crane and is connected with a PLC (programmable logic controller) of the overhead travelling crane. Remote control can be realized by the operation control system, so that operators can accurately control grab cranes while being away from severe environments.

Owner:LUOYANG JIANGUANG SPECIAL EQUIP

Ocean-environmental antifouling coating and preparation method thereof

InactiveCN106634344AAvoid contamination damageEfficient antifoulingAntifouling/underwater paintsPaints with biocidesEpoxyEnvironmental resistance

The invention discloses an ocean-environmental antifouling coating and a preparation method thereof. The ocean-environmental antifouling coating is composed of, by weight part, 60-80 parts of silicon-modified acrylic resin, 12-14 parts of talcum powder, 3-5 parts of environmental antifouling agent, 40-60 parts of water-borne acrylic-modified epoxy resin, 1-3 parts of bentonite, 3-5 parts of zinc oxide, 5-6 parts of minerals, 5-7 parts of glyoxal, 4-6 parts of ferric oxide red, 6-8 parts of isophorone, 3-5 parts of silane coupling agent, 4-6 parts of butanol and 1-3 parts of organic solvent. The ocean-environmental antifouling coating contains no hazardous substances such as organic tin and cuprous oxide which can cause severe hazards to marine ecological environment, avoids environment pollution and destruction. By reducing the interface energy and matching with the environmental organic antifouling agent, the ocean-environmental antifouling coating can achieve efficient antifouling performance.

Owner:QINZHOU UNIV

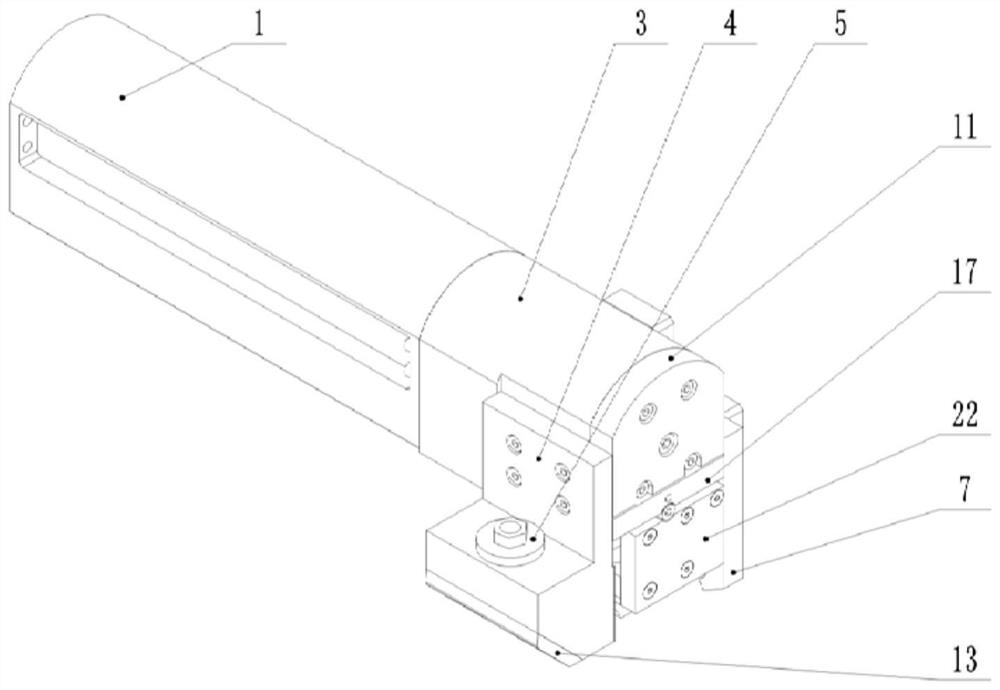

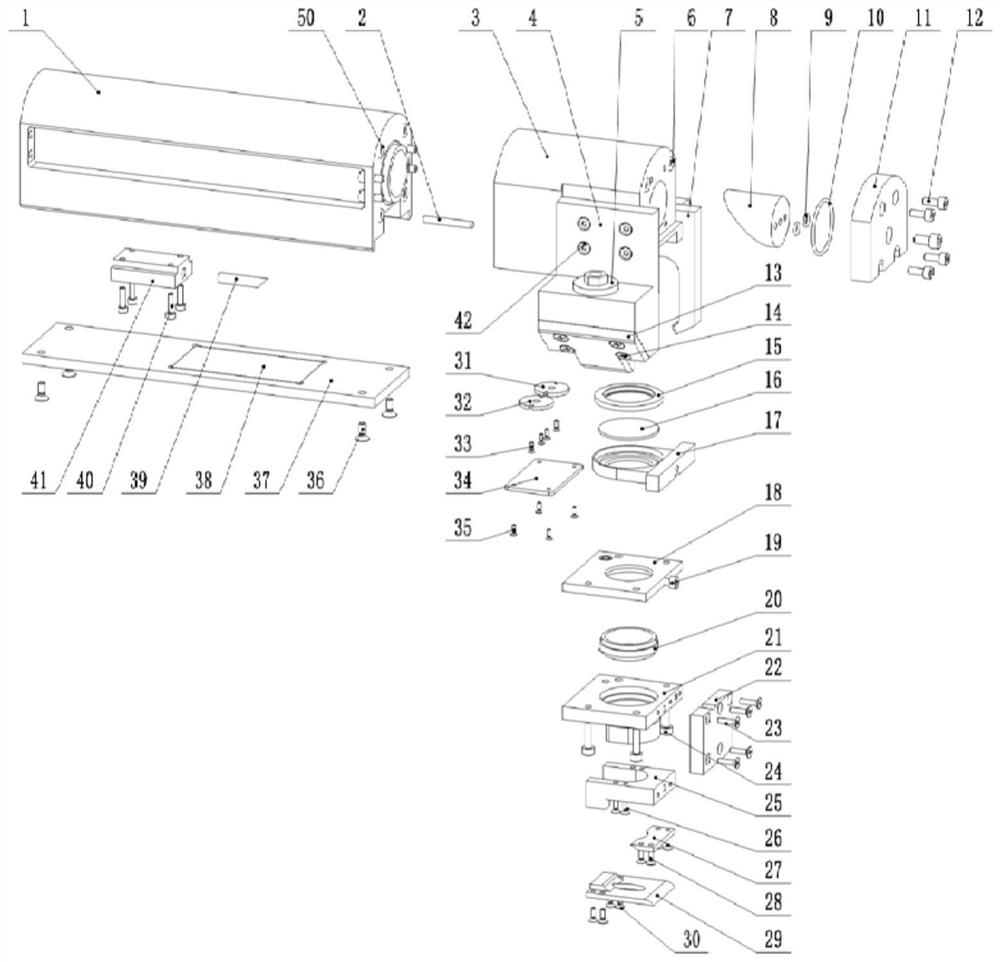

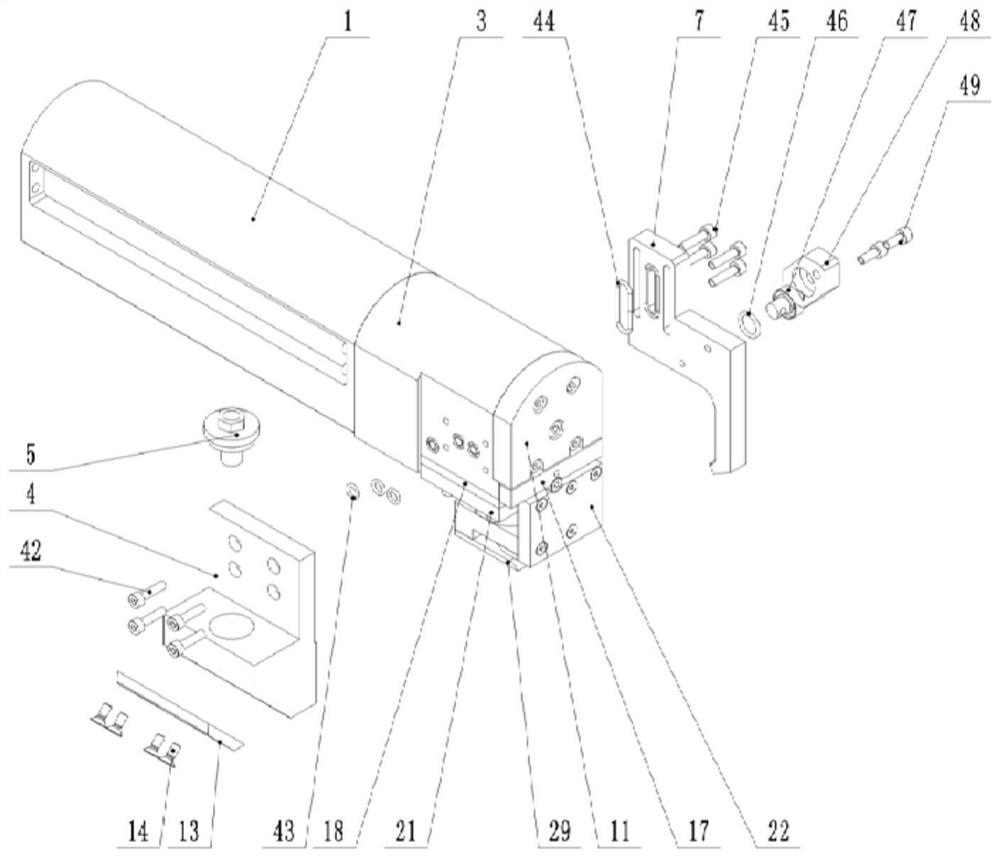

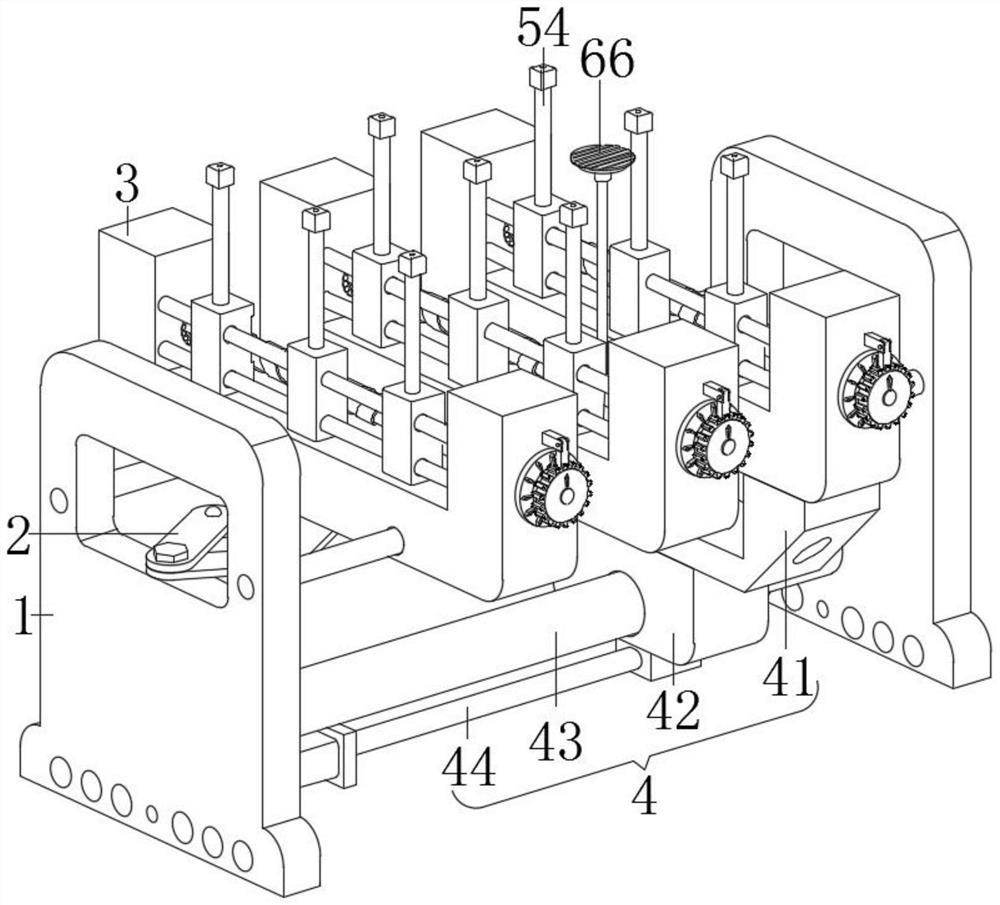

Integrated wide-light-spot deep-hole laser cladding head

ActiveCN111926324AExtended service lifeAvoid contamination damageIncreasing energy efficiencyMetallic material coating processesAir knifeMaterials science

The invention discloses an integrated wide-light-spot deep-hole laser cladding head. The integrated wide-light-spot deep-hole laser cladding head comprises a connection rod, a fixed seat, a powder feeding unit, a cleaning unit, an integral mirror unit, a protective mirror unit, a flow-guide air knife unit, an illumination unit and a camera shooting unit, wherein the connection rod is connected tothe rear end of the fixed seat; the integral mirror unit is installed at the front end of the fixed seat; the powder feeding unit is installed at one side of the fixed seat; the cleaning unit is installed at the other side of the fixed seat; the flow-guide air knife unit is installed at the lower side of the fixed seat and located between the powder feeding unit and the cleaning unit; the protective mirror unit is installed between the fixed seat and the flow-guide air knife unit; the illumination unit is installed on the fixed seat; the camera shooting unit is installed on the connection rod;and the illumination unit is located between the camera shooting unit and the powder feeding unit. According to the integrated wide-light-spot deep-hole laser cladding head, through innovative arrangement for an upper air knife structure and a lower air knife structure, the laser cladding head is effectively protected, and the cladding efficiency is increased; and through innovative arrangement for a camera shooting function, a molten pool, a powder spreading state, and the quality of a cladding surface can be observed in real time, so that an operator can find cladding quality problems in real time.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

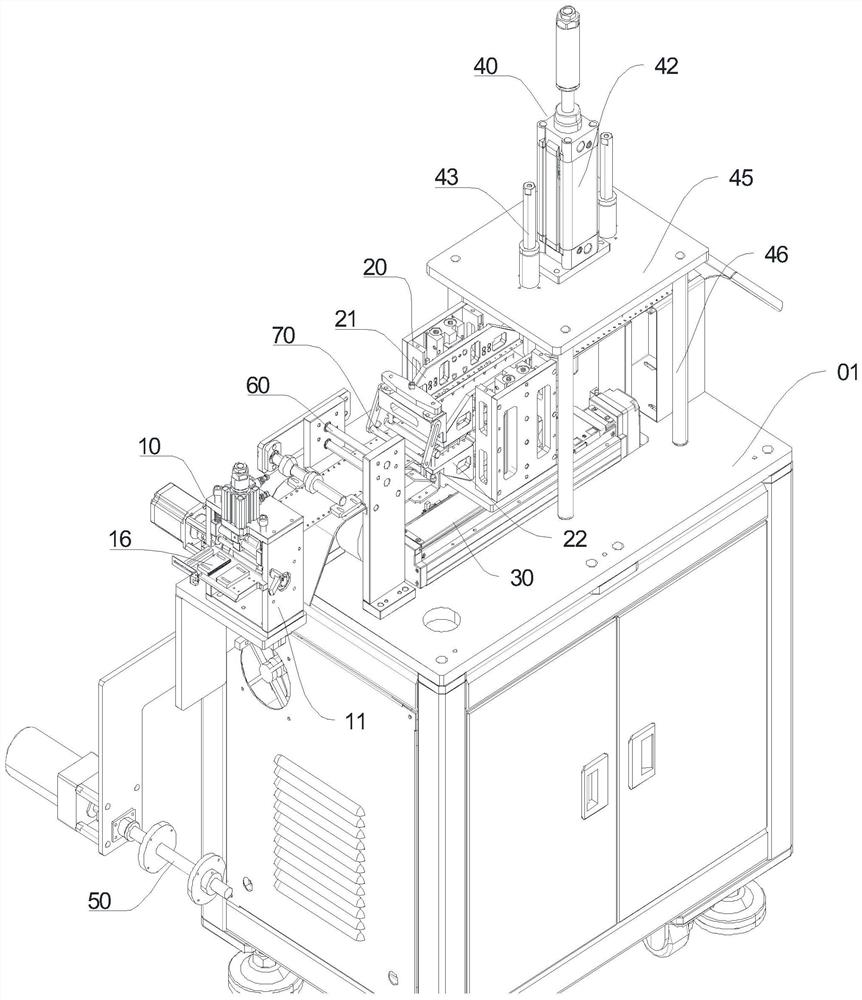

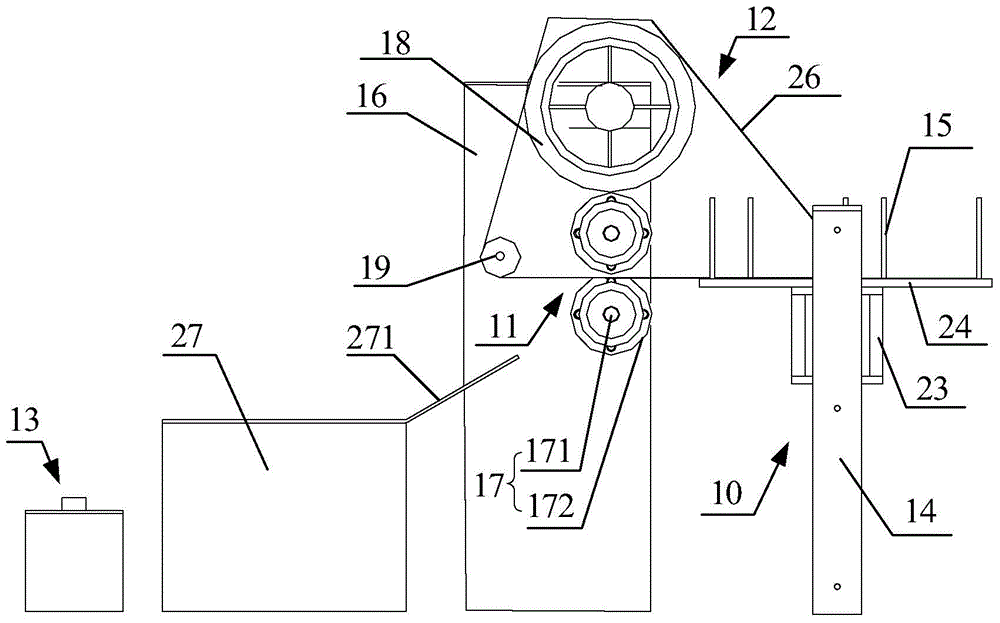

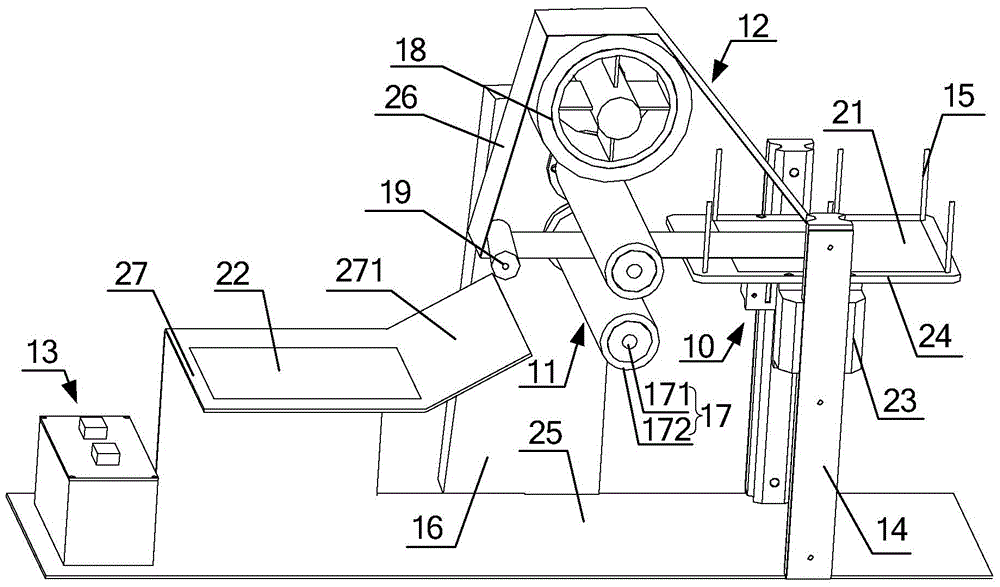

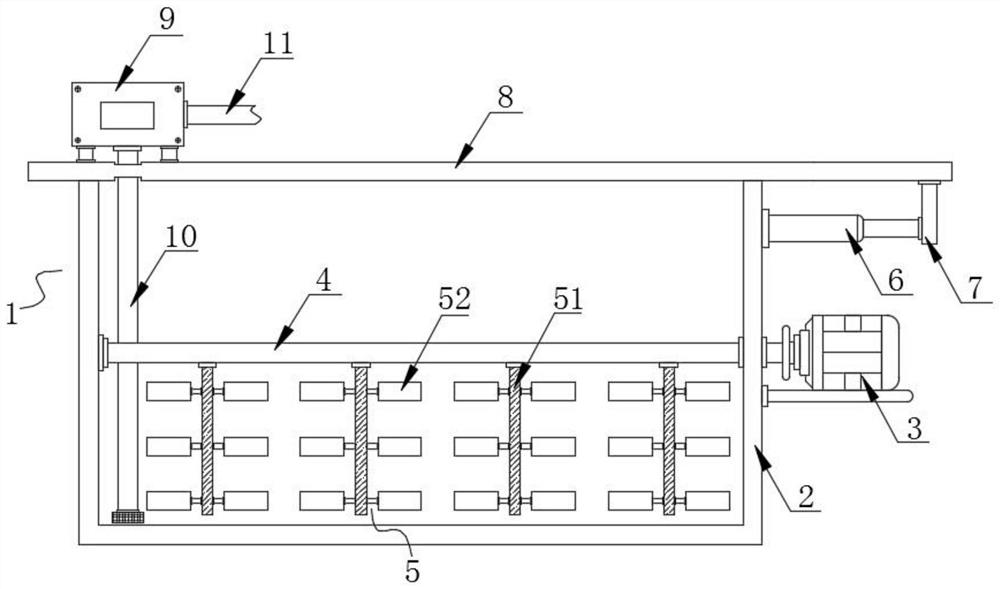

Double-layer film material aligning and lamination assembly line

PendingCN112172302AReduce exposure timeAvoid contamination damageLamination ancillary operationsLaminationWaste collectionAssembly line

The invention discloses a double-layer film material aligning and lamination assembly line, a waste collection module, an aligning module and a material pressing module are sequentially connected in the X direction, and a material pulling module is arranged below the aligning module; and upper and lower layers of film materials respectively enter the aligning module from the upper and lower sidesof the waste collection module in the X-direction forward direction, and a protective film is reversely fed from the waste collection module in the X-direction. An alignment needle is arranged on an alignment plate of the aligning module; the alignment needle moves forwards in the Z direction and penetrates through a material belt hole correspondingly formed in the edge of the double-layer film material, and at the moment, the material pulling module drives the alignment plate and the film material to move to the material pressing module; the alignment needle reversely moves in the Z direction, the edge of the film material is separated from the alignment needle, the material pulling module drives the alignment plate to move to the original position, and alignment is started to be conducted on a next site of the double-layer film material; and a pressing plate of the material pressing module is used for laminating the upper and lower layers of film materials in the Z direction. An automatic structure is adopted, the technological process is optimized, and the production efficiency is greatly improved.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

Green efficient ecological printing and dyeing method

InactiveCN111172786AMaintain vividnessPrinting and dyeing quality is reliableFibre treatmentSingeingEnvironmental engineeringDesizing

The present invention discloses a green efficient ecological printing and dyeing method. The method comprises the following steps of 1) preparing original cloth; 2) (1) performing fabric singeing, (2)performing fabric desizing, (3) performing fabric scouring and (4) performing fabric bleaching; 3) preparing a dye; 4) performing dyeing; 5) performing cleaning; and 6) performing drying. The invention belongs to the technical field of printing and dyeing, and particularly provides the green efficient ecological printing and dyeing method which keeps the color brilliance, does not damage and injure a fabric and the human body, and avoids the environmental pollution and damage by more environment-friendly dye preparation and printing and dyeing methods.

Owner:威海华偲家纺股份有限公司

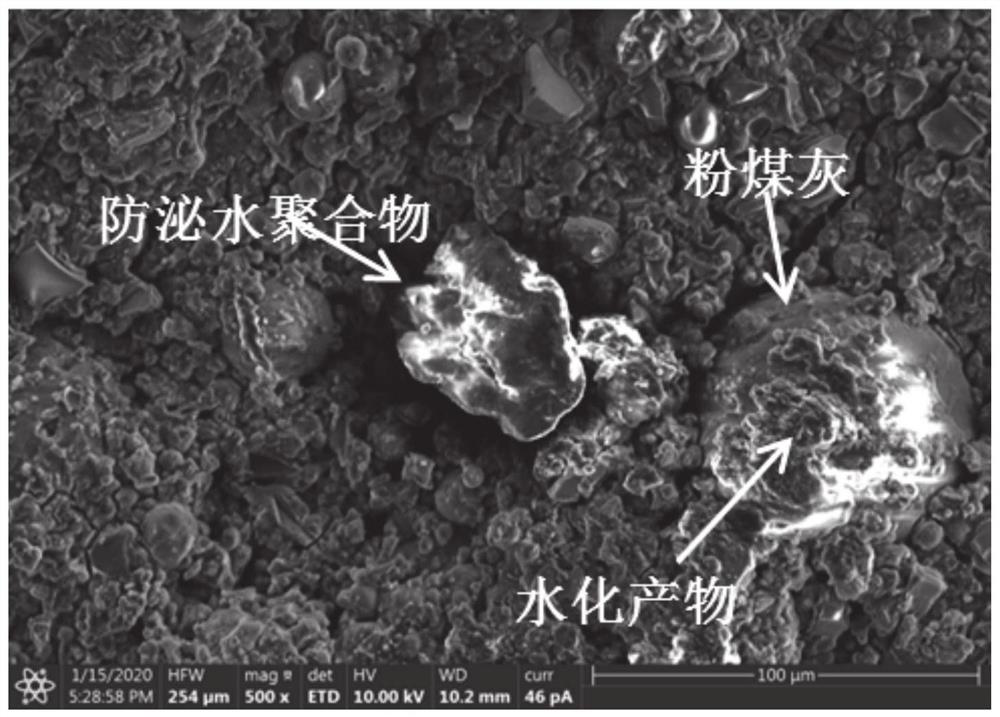

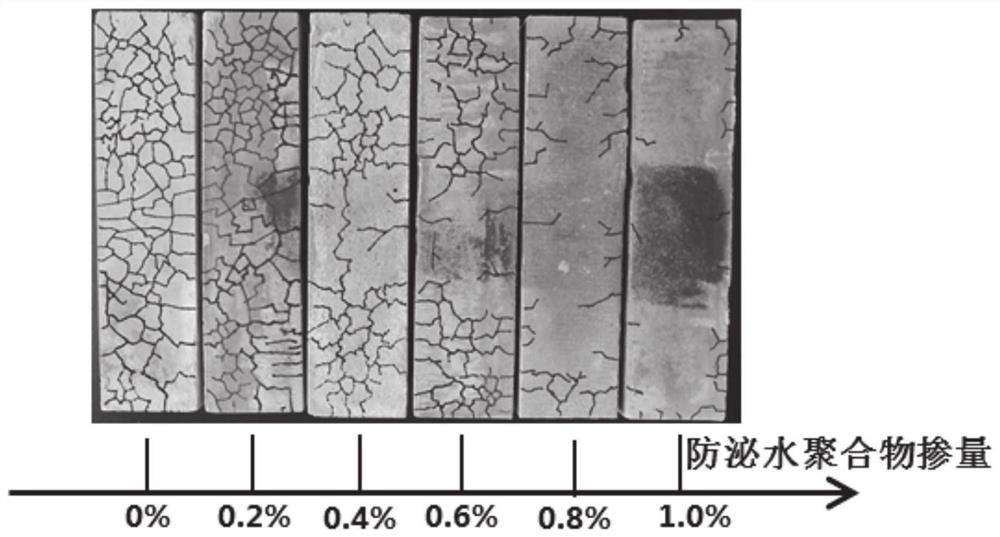

Anti-bleeding polymer, low-retraction filling solid waste material, preparation method and application

The invention discloses an anti-bleeding polymer, a low-retraction filling solid waste material, a preparation method and an application. The anti-bleeding polymer is at least prepared from the following components: acrylic acid, acrylamide, an initiator, a cross-linking agent, deionized water, sodium hydroxide and a surface cross-linking agent. The low-retraction filling solid waste material is prepared from the following components in parts by weight: 500-1000 parts of fly ash, 500-1000 parts of blast furnace slag, 30-300 parts of water glass, 0-500 parts of Portland cement, 300-1200 parts of water, 10-1000 parts of sodium hydroxide and 2-20 parts of an anti-bleeding polymer. Aiming at the volume retraction phenomenon of a common solid waste cementing material caused by the bleeding problem in the hydration reaction process, the invention provides an anti-bleeding polymer, so that the retraction of the solid waste grouting material caused by bleeding is effectively reduced, and the roof contact rate of the solid waste grouting material to coal mine filling is improved; the anti-bleeding polymer can guarantee the humidity environment of the solid waste cementing material in the hydration process by slowly releasing water, the generation amount of C-SH is increased, and therefore the strength of a solidified body is improved.

Owner:SHANDONG UNIV

Biological insecticide for preventing insect pest of orchard as well as preparation method and application method thereof

InactiveCN109362814AStrong specificityPersistent infectionBiocideAnimal repellantsFruit treeTree trunk

The invention discloses a biological insecticide for preventing insect pest of an orchard as well as a preparation method and application method thereof. The biological insecticide is prepared by virtue of the following preparation method: slicing and decocting radix stemonae, filtering to obtain a radix stemonae solution, and diluting the radix stemonae solution by using water to obtain the diluted radix stemonae solution; inoculating and culturing beauveria bassiana to obtain a beauveria bassiana culture solution, cutting off the stems and leaves of the stemona, grinding into juice, uniformly mixing, sealing and anaerobically fermenting in a fermentation tank together with the beauveria bassiana culture solution, filtering a fermented product to obtain a fermented solution, and filteringto obtain the fermented filter residues; and diluting the fermented solution by using water to obtain the diluted fermented solution. The application method comprises the steps: mixing the diluted radix stemonae solution and diluted fermented solution according to a volume ratio of 1: 1; and spraying the mixed solution to fruit trees or pouring the mixed solution into original holes of the fruittree trunks or pouring the mixed solution into artificial hole of the fruit trees, or uniformly mixing, and uniformly mixing with the fermented filter residues and earth, and sealing the holes of thefruit tree trunk or smearing the mixture onto the fruit tree trunk.

Owner:珠海德源现代农业科技有限公司

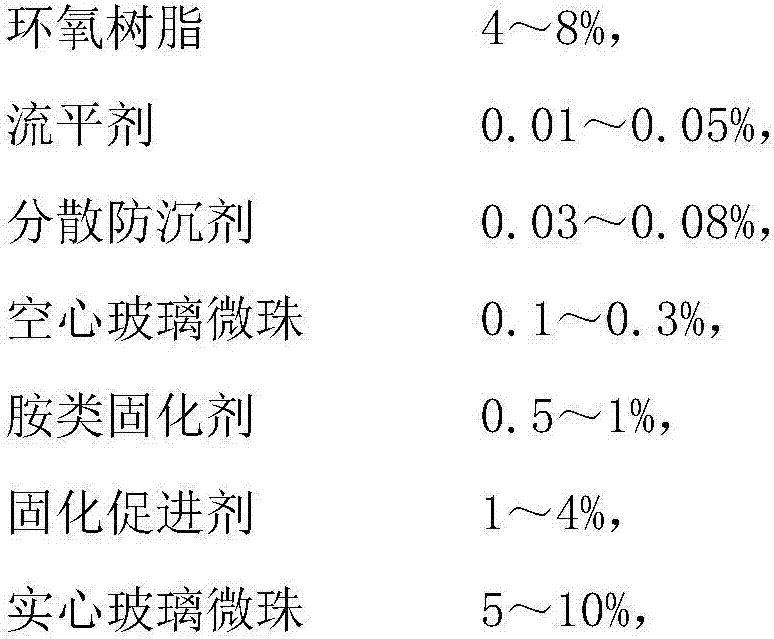

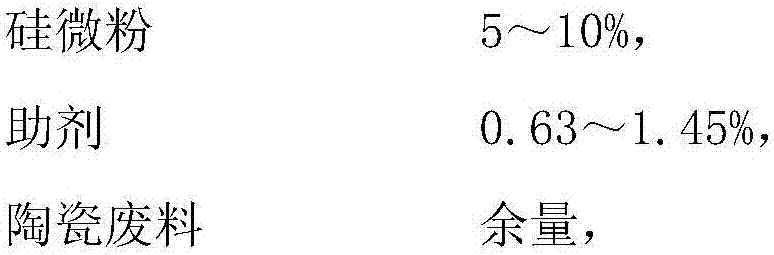

Mineral casting material filled with ceramic waste, application thereof and products

The invention relates to the technical field of mineral casting and discloses a mineral casting material filled with ceramic waste, application thereof and products. The mineral casting material filled with ceramic waste comprises the following components by weight percent: 4-8% of epoxy resin, 0.01-0.05% of a leveling agent, 0.03-0.08% of a dispersing anti-settling agent, 0.1-0.3% of hollow glassbeads, 0.5-1% of an amine curing agent, 1-4% of a curing accelerator, 5-10% of 100-200-mesh solid glass beads, 5-10% of 800-1500-mesh quartz powder, 60-90% of ceramic wastes and 0.63-1.45% of an additive. According to the technology of the invention, the material formula is improved and the ceramic waste is used as a filling material of the mineral casting, so that the equipment precision and surface rigid wearing resistance of the mineral casting can be promoted, the environmental protection effect is greatly promoted; the core of the ceramic waste is adopted for controlling the sizes of theceramic particles; the ceramic particles in different diameters are adopted for guaranteeing the strength, hardness and stability of the products.

Owner:湖南国汇新材料股份有限公司

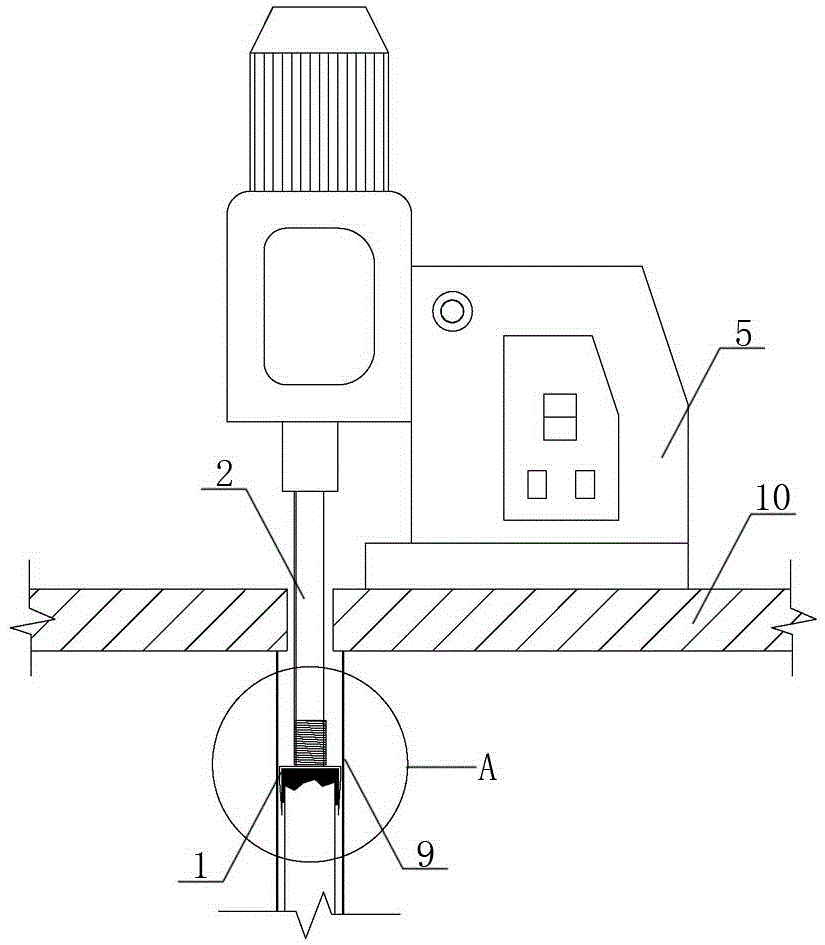

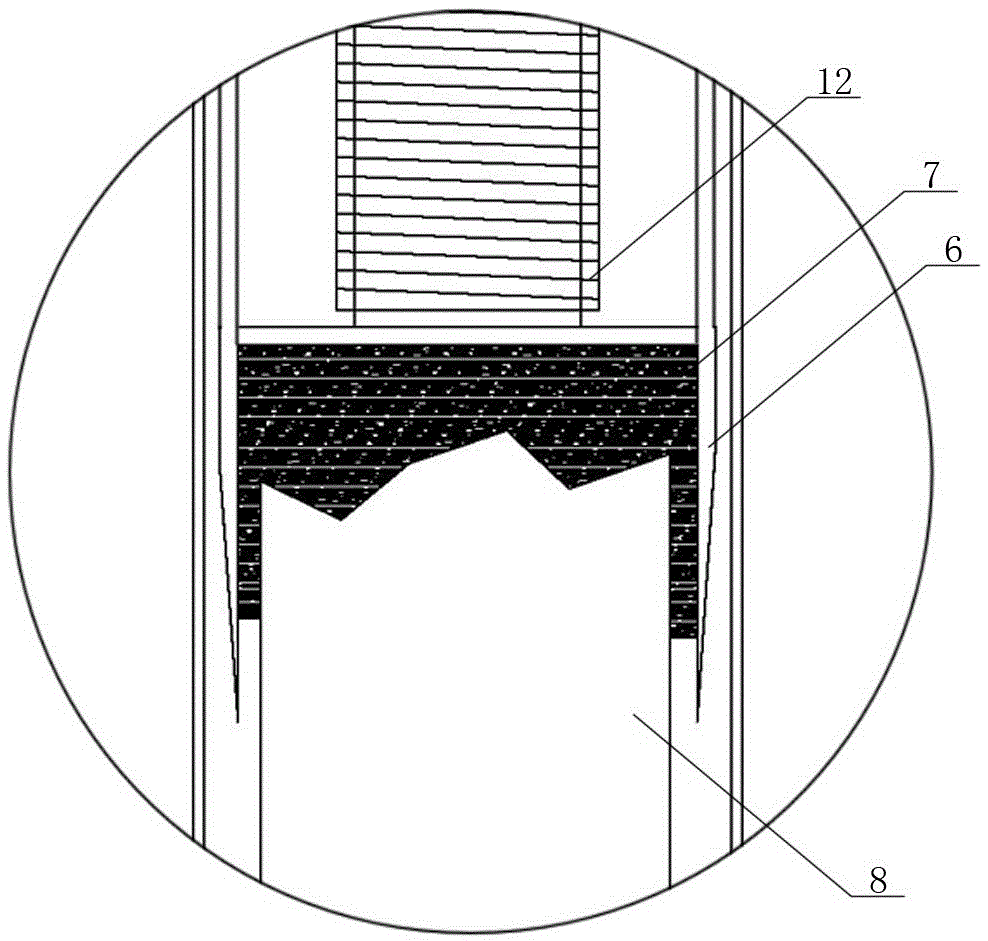

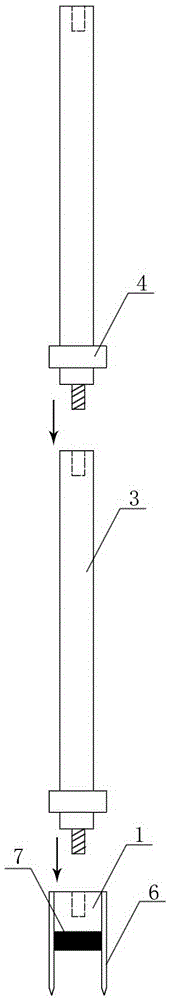

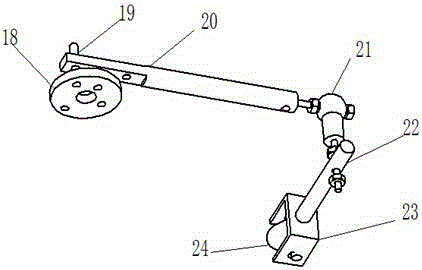

Rod taking device for broken rod of thread connecting rod piece and construction method thereof

ActiveCN106593326AAchieve replacementEliminate construction hazardsDrilling rodsDrilling casingsArchitectural engineeringEngineering

The invention provides a rod taking device for a broken rod of a thread connecting rod piece and a construction method thereof. The rod taking device comprises a drilling machine base and a drilling rod connected to the drilling machine base. A connecting connector is detachably connected to the end of the drilling rod, and the drilling rod is formed through ordinal and detachable connection of a set of rod sections. For prestress construction, when the rod piece is broken, the indwelled broken rod basically cannot be taken out due to the facts that the size of a construction hole of the thread connecting rod piece is small, the depth of the construction hole is more than three meters, and the diameter is less than 50 mm. According to the rod taking device for the broken rod of the thread connecting rod piece and the construction method thereof, the indwelled broken rod indwelled in the structure construction hole can be taken out, replacement of the thread connecting rod piece is achieved, construction hazards are eliminated, meanwhile a great deal of maintenance cost is reduced, and the economic value is improved.

Owner:BEIJING JANDC GEOTECHNICAL CONSTR LTD +1

Intelligent ammeter

InactiveCN110261655AAvoid damageSimple structureFire rescueModifications by conduction heat transferEngineeringCopper

The invention discloses an intelligent ammeter. The intelligent ammeter comprises an installation box, wherein an inner cavity is arranged in the installation box, an ammeter is arranged in the inner cavity, heat dissipation devices which are vertically symmetrical and are used for dissipating heat of the ammeter are arranged on the upper side and the lower side of the inner cavity, a fire extinguishing device used for extinguishing fire of the ammeter is arranged on the left side of the inner cavity, and a shielding device used for preventing powder from extinguishing fire from polluting the ammeter is arranged on the right side of the inner cavity. The intelligent ammeter is simple in structure, the aluminum sheet and the copper pipe are used for radiating heat under the driving of a hot air fan, the ammeter is sealed and protected, the fire extinguishing powder is reused for efficiently extinguishing fire, damage to other parts in the fire extinguishing process is avoided, and the powder is prevented from polluting and damaging the device.

Owner:胡云鑫

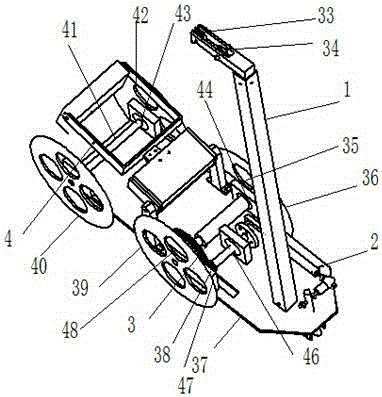

Automatic goods collecting trolley driven by potential energy

The invention relates to an automatic goods collecting trolley driven by potential energy, and belongs to the technical field of engineering application. The automatic goods collecting trolley comprises a supporting mechanism, a steering mechanism, a transmission mechanism and an automatic goods collecting mechanism. The supporting mechanism is fixedly connected to a bottom plate of the transmission mechanism through a supporting rod and a base. The steering mechanism is connected with a driving shaft of the transmission mechanism through a rotary disc. The transmission mechanism is fixed to the bottom plate through a bearing pedestal. The automatic goods collecting mechanism and the bottom plate of the transmission mechanism are fixed through a vertical supporting frame I and a vertical supporting frame II. The gravity potential energy can be adopted as driving force, the various mechanisms are reasonably utilized, an automatic goods collecting device is adopted, energy can be effectively saved, and part of manpower resources are saved.

Owner:KUNMING UNIV OF SCI & TECH

Environment-friendly long-acting self-secretion anti-corrosion paint and preparation method thereof

PendingCN106978056ASimple preparation processAvoid contamination damageAnti-corrosive paintsPolyurea/polyurethane coatingsSolventHydrolysis

The invention relates to environment-friendly long-acting self-secretion anti-corrosion paint and a preparation method thereof. The environment-friendly long-acting self-secretion anti-corrosion paint is prepared from aromatic environment-friendly preservatives, degradable polypolyol, diisocyanate, acrylic acid based self-polishing resin, chain expanding agents, catalysts and a first solvent. The anti-corrosion paint optionally contains urethane acrylate. The anti-corrosion paint has the advantages that an environment-friendly effect is achieved; during ship navigation and ship stop, preservatives can be peeled off by self through hydrolysis and can be slowly and uniformly released; the dependence on ship navigation speed is reduced; the long-acting anti-corrosion effect can be achieved on ships, submarines, offshore production platform facilities and the like. A process for preparing the environment-friendly long-acting self-secretion anti-corrosion paint is simple, and is applicable to industrial production.

Owner:XINGTAI UNIV

Non-pollution duplex extracting method for scene fingerprints and DNA thereof

InactiveCN108498103AIntegrity guaranteedEfficient acquisitionDiagnostic recording/measuringSensorsInvestigation methodsComputer science

The invention relates to a police investigation method, in particular to a non-pollution duplex extracting method for scene fingerprints and DNA of the scene fingerprints. The method comprises the following steps: S1, carrying out brushing display on the fingerprints by adopting a disinfected and inactivated disposable fingerprint magnetic powder brush and disinfected and inactivated magnetic powder; S2, collecting the information of the scene fingerprints; and S3, extracting DNA information of the scene fingerprints. According to the method provided by the invention, the disposable fingerprint magnetic powder brush and the disinfected and inactivated magnetic powder are adopted for carrying out brushing display on the fingerprints, the disposable fingerprint magnetic powder brush and themagnetic powder are subjected to disinfection and inactivation, do not carry biological DNA information, and are not recycled after use, so that the pollution and damage caused to DNA in the scene fingerprints by the repeatedly used brush and magnetic powder are prevented, and investigation personnel can efficiently and rapidly acquire the identity information of suspects.

Owner:李刚 +2

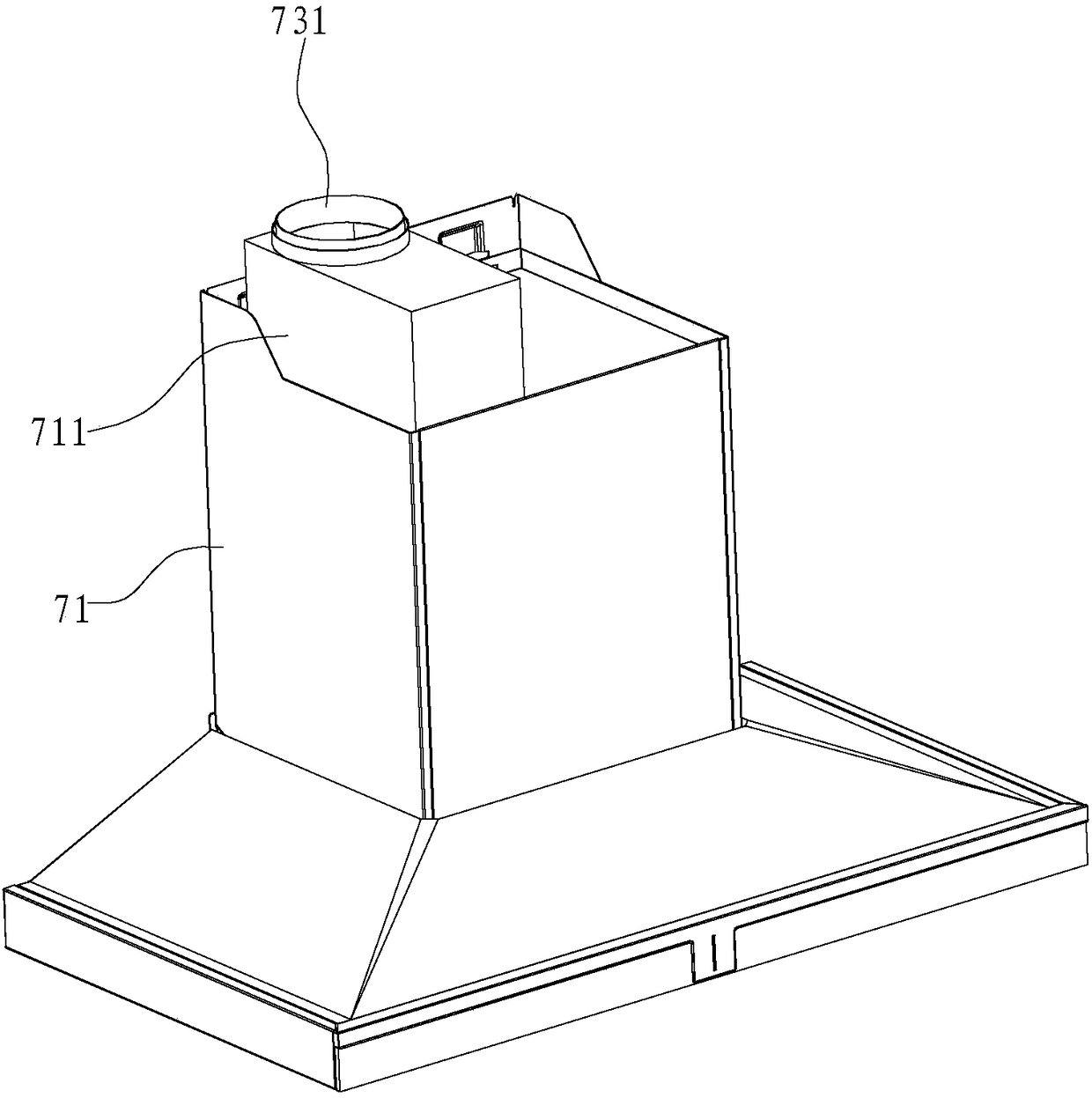

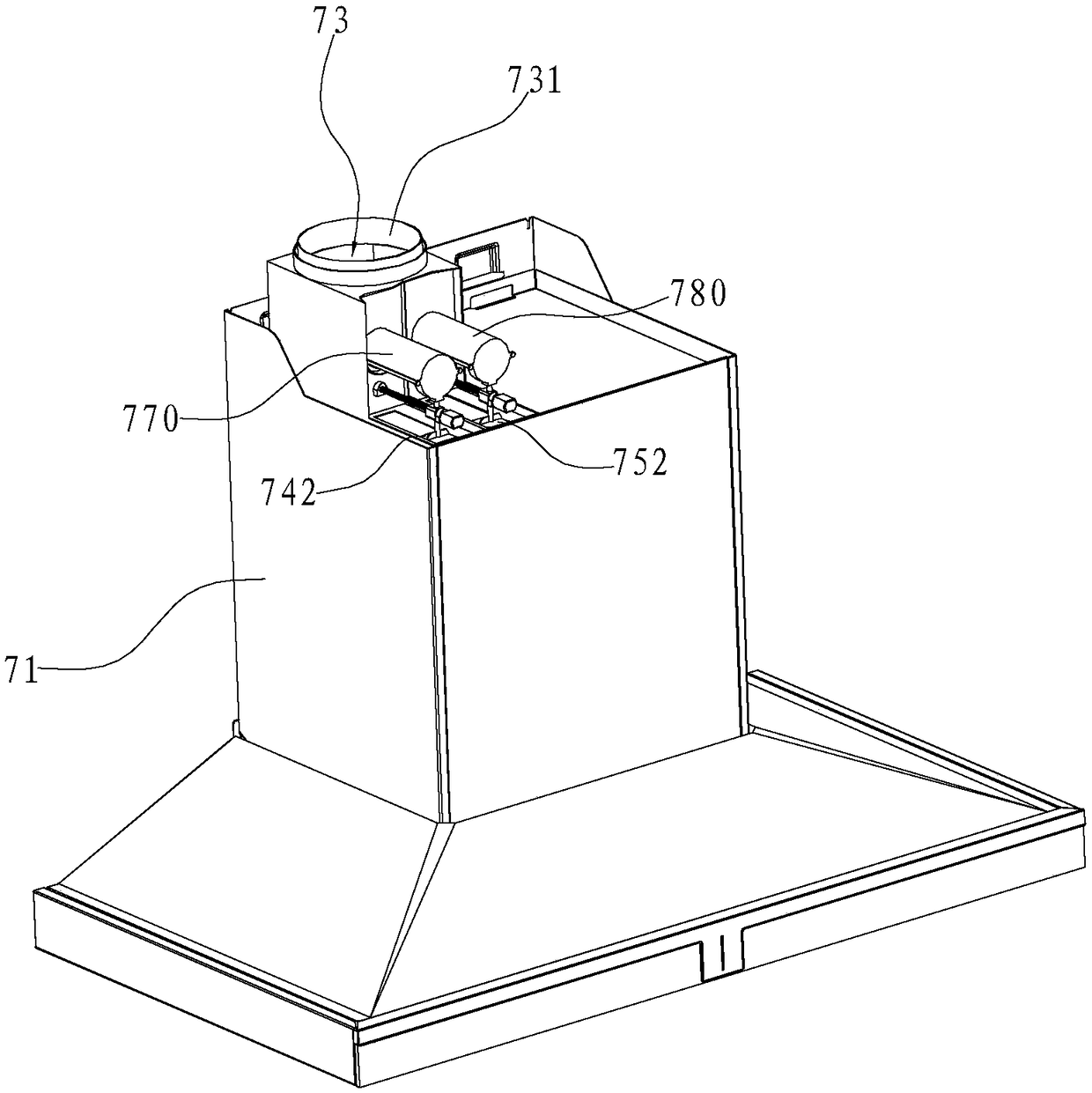

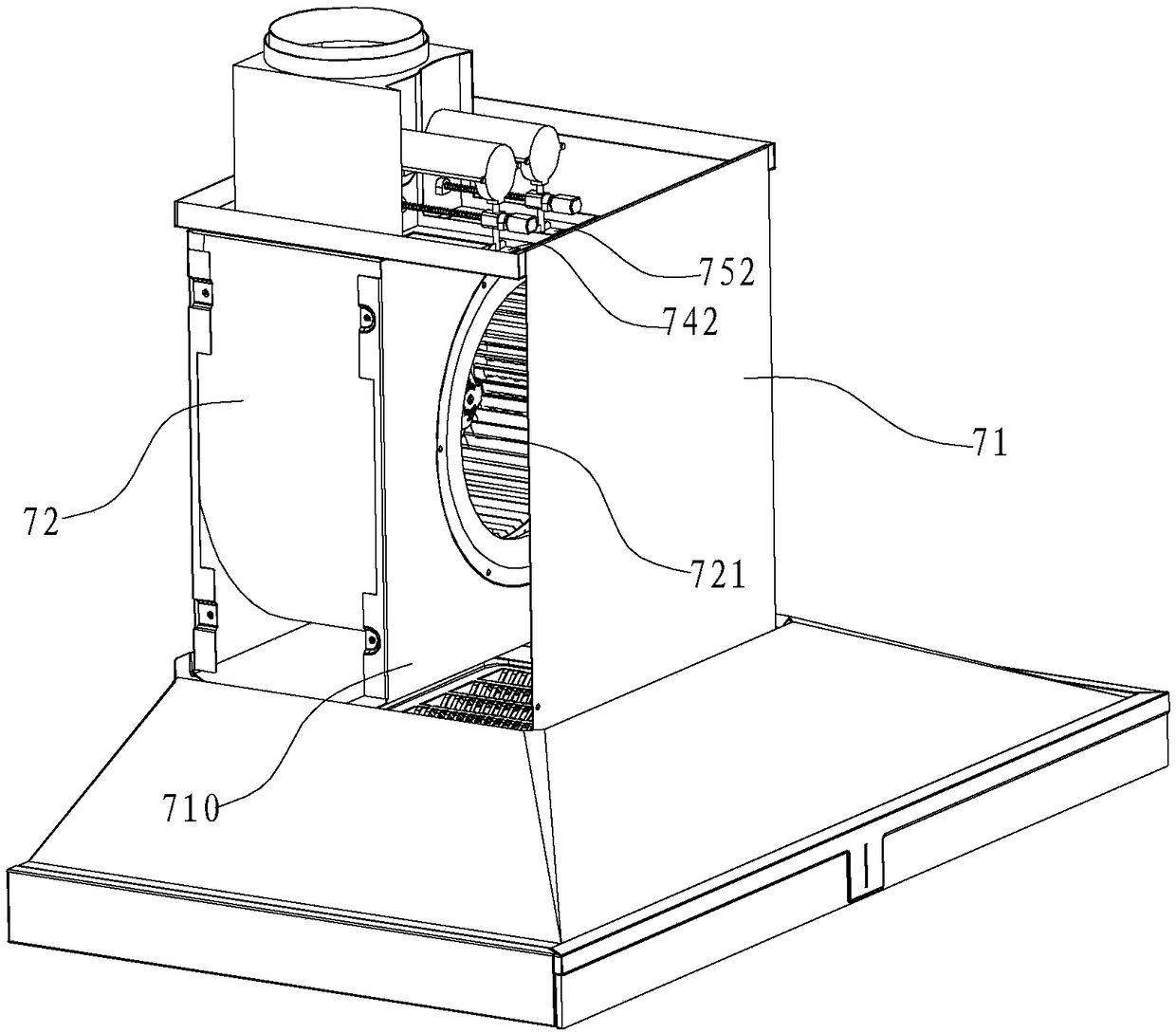

Extractor hood

PendingCN108240655AUniform ozone concentrationAvoid concentration unevennessDomestic stoves or rangesLighting and heating apparatusTreatment effectAirflow

The invention relates to an extractor hood. The extractor hood comprises an air outlet chamber and a purification chamber. The purification chamber and the air outlet chamber are arranged side by side. The purification chamber is provided with a first air inlet and a first air outlet. A sterilization device, a first mounting base and a first movement assembly are arranged in the purification chamber. The sterilization device is driven by the first movement assembly to move back and forth between the air outlet chamber and the purification chamber and at least has two states. In the first state, at least one part of the sterilization device is located in the air outlet chamber and the first and second air outlets are open. In the second state, the sterilization device is completely locatedin the purification chamber, and the first air inlet and the first air outlet are both closed. In the cooking state, the sterilization device can be placed in a closed space so that the soot-caused pollution damage to the sterilization device is avoided. The airflow generated by a fan can effectively diffuse and flow the ozone, so that the ozone concentration in the extractor hood is uniform and the treatment effect of ozone on the interior of the extractor hood is guaranteed.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

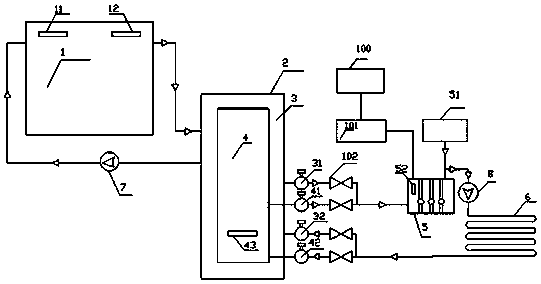

Solar-gas heating integrated system

PendingCN108375100AReduce in quantityLower heating costsSolar heating energyLighting and heating apparatusGas heaterSolar water

The invention discloses a solar-gas heating integrated system, which comprises a solar water heater, a heat exchange and heat storage water tank, a gas heater and an end radiator; the solar water heater, the heat exchange and heat storage water tank, the gas heater and the end radiator are sequentially communicated through hot water guide pipes, and the end radiator, the heat exchange and heat storage water tank and the solar water heater are sequentially communicated through cold water guide pipes; a first temperature sensor and a water level sensor are arranged inside the solar water heater,the heat exchange and heat storage water tank is provided with a heat exchange layer and a heat storage layer, a second temperature sensor is arranged in the heat exchange and heat storage water tank, each of the heat exchange layer and the heat storage layer is connected in parallel with the gas heater through an independent hot water guide pipe, a first heat exchange valve is arranged between the heat exchange layer and the gas heater, and a first heat storage valve is arranged between the heat storage layer and the gas heater. The solar-gas heating integrated system solves the problem thatthe environment can be polluted and destroyed by bulk coal burning in a heating season, energy consumption is reduced, and home-owned solar equipment can be utilized for construction.

Owner:郑海英

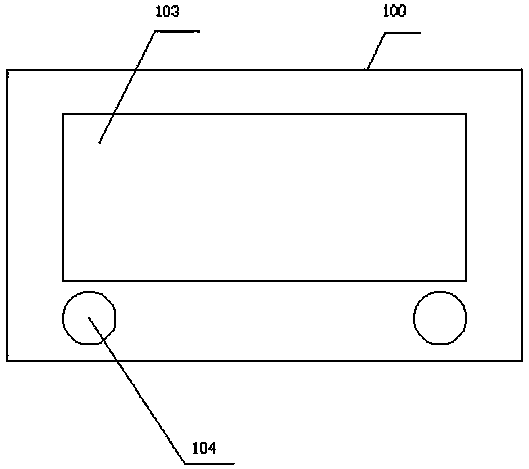

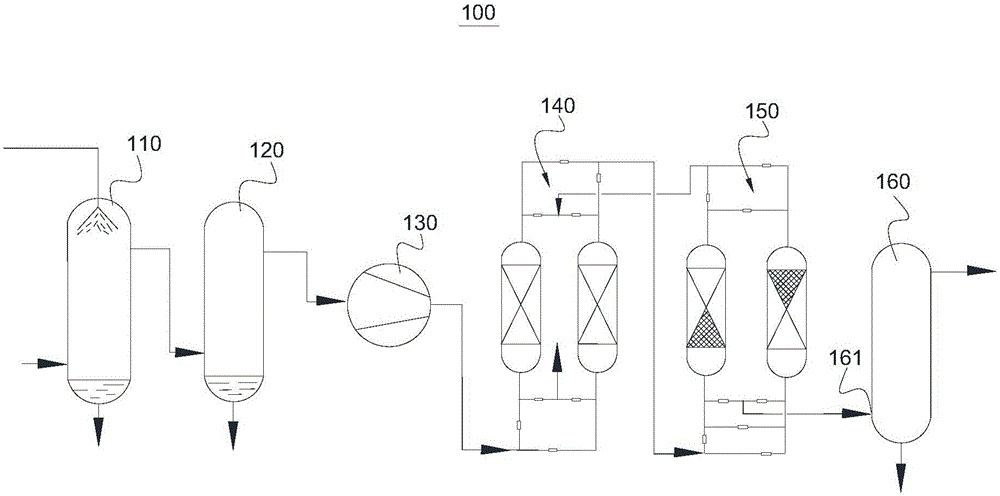

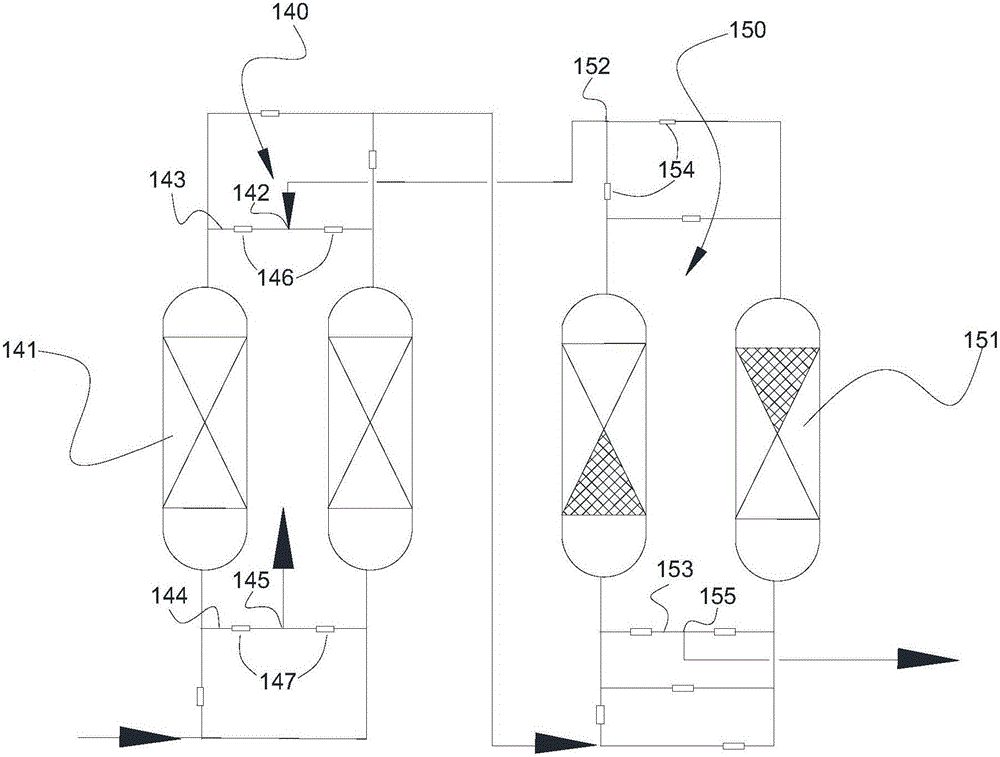

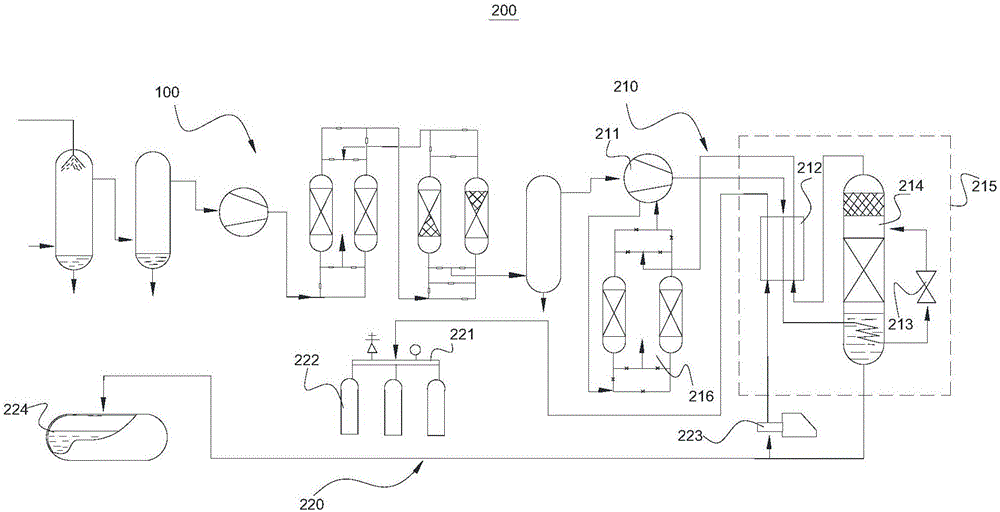

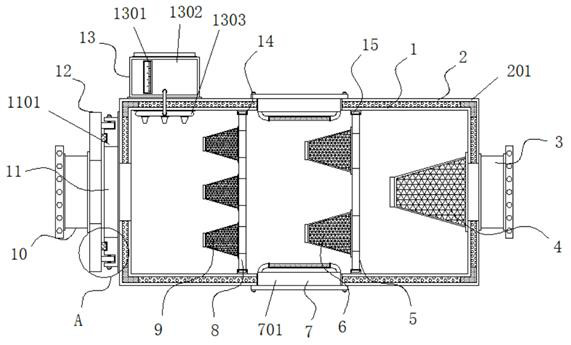

Purifying device and method decarbonizing nitric acid industry tail gas to extract N2O

PendingCN106731497AImprove qualityIncrease production capacityNitrous oxide captureGas treatmentSorbentHigh pressure

The invention relates to the technical field of chemical substance recycling and provides a purifying device and method decarbonizing nitric acid industry tail gas to extract N2O. The decarbonizing purifying device comprises a dryer provided with water-removing absorbent and pressure swing adsorption equipment provided with decarbonizing absorbent. The method includes: using a washing tower to wash raw material gas, using a buffer tank to remove free moisture in the raw material gas, using first compression cooling device to pressurize the raw material gas, using the dryer to dehydrate the raw material gas, and using the pressure swing absorption equipment to remove non-polar gas in the raw material gas. The method has the advantages that the physical immunity removing and high-pressure throttling refrigeration rectification process is used; compared with a method chemically decarbonizing other tail gas to recycle N2O, the method can avoid waste alkaline liquid secondary pollution and is low in cost and convenient and safe to operate.

Owner:杨刘月

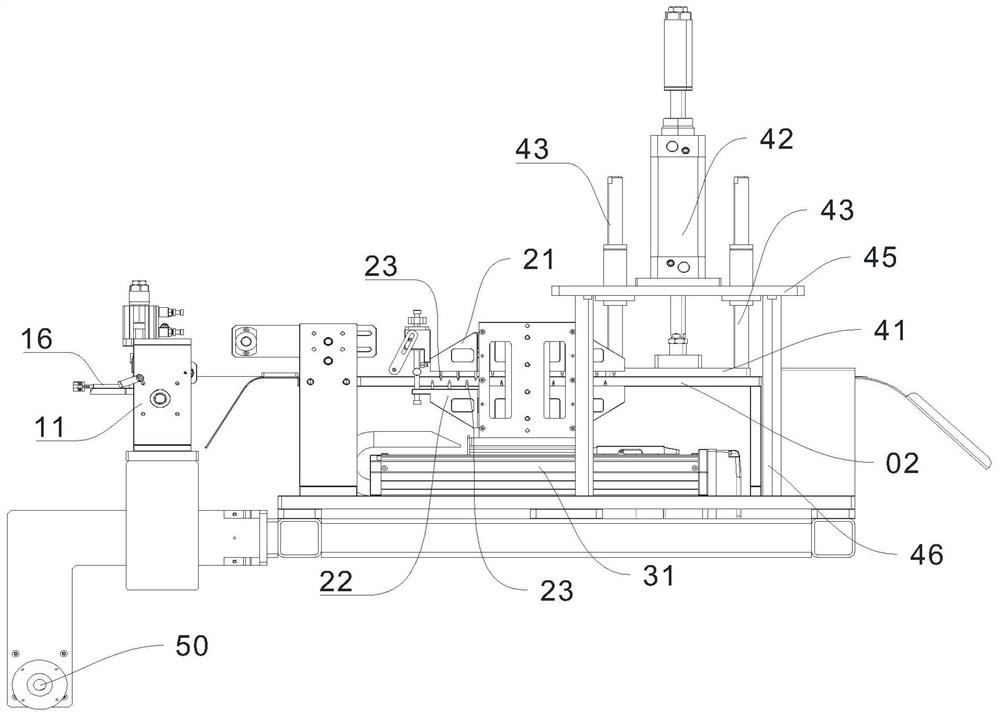

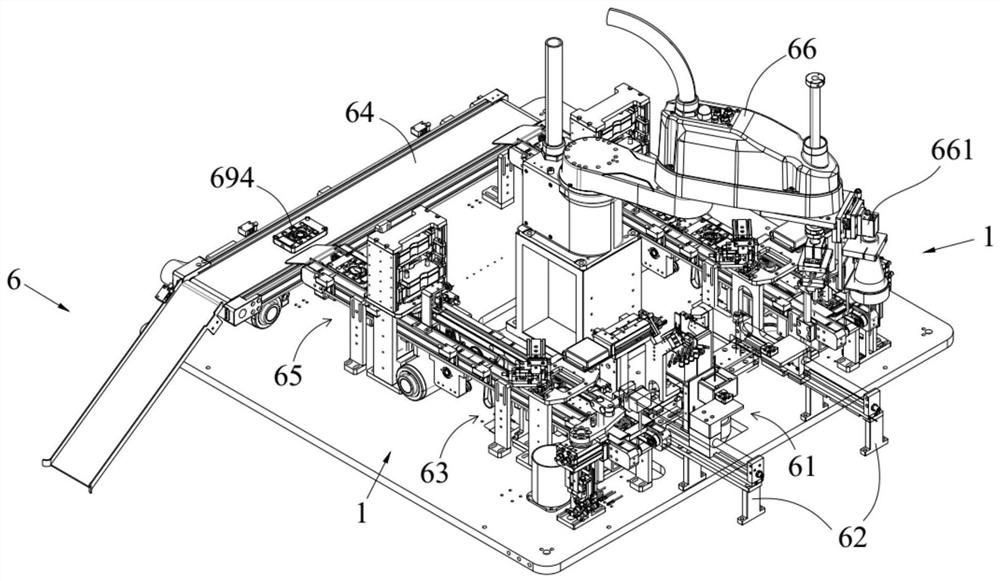

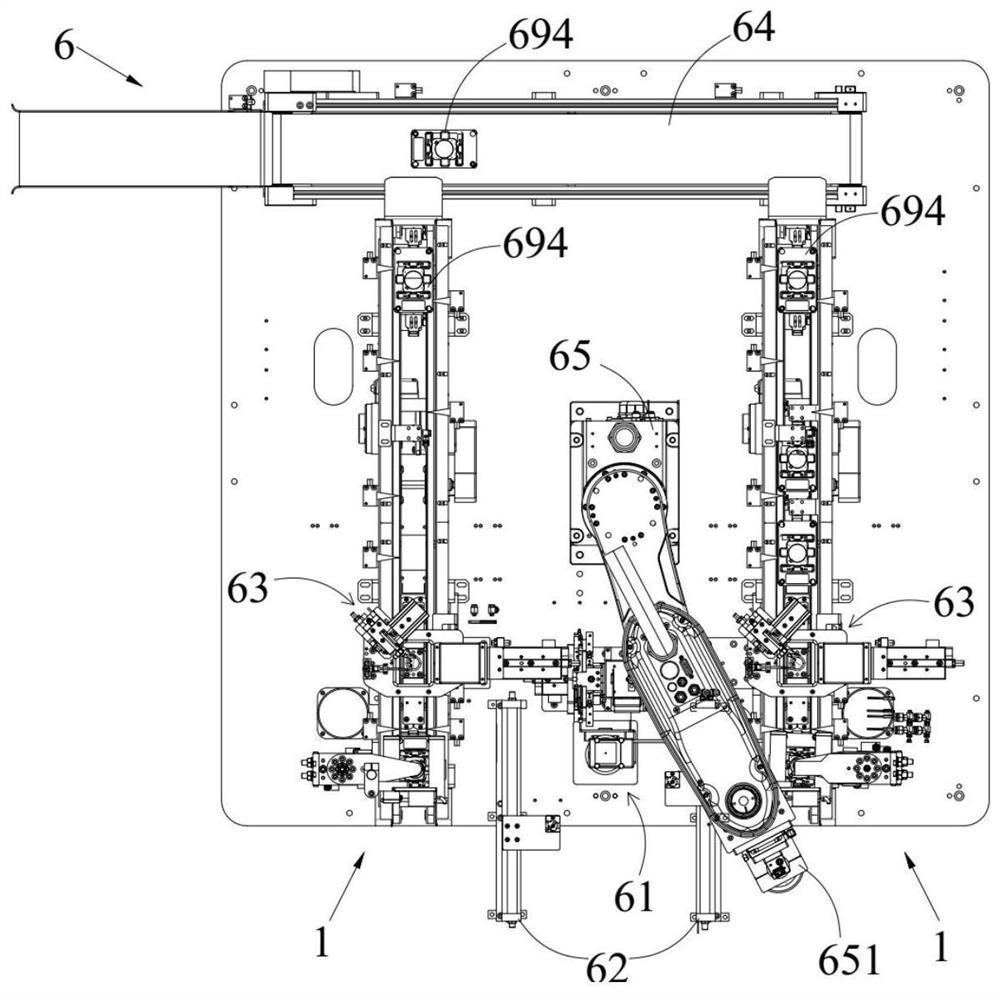

Film tearing and pressure maintaining integrated assembly line

ActiveCN112643308AReduce the number of rotationsAvoid contamination damageFinal product manufactureArticle unpackingThin membraneEngineering

The invention discloses a film tearing and pressure maintaining integrated assembly line which comprises: two oppositely-arranged material disc conveying lines which are arranged in parallel in a spaced mode to form a mounting space located between the two material disc conveying lines; a workpiece film tearing mechanism which is arranged in the mounting space and used for tearing off a film on the surface of the workpiece, wherein the thin film is attached to the lower surface of the workpiece body and protrudes out of the edge of the workpiece body to form at least one clamping part; a workpiece carrying mechanism, wherein one end of the workpiece carrying mechanism extends to the upstream of the material disc conveying lines, and the other end of the workpiece carrying mechanism extends to the side of the workpiece film tearing mechanism; and an assembling manipulator which is arranged in the mounting space and is adjacent to the workpiece film tearing mechanism. According to the invention, the number of times of product circulation and positioning can be reduced, so that the film tearing and assembling efficiency is improved, and the assembled product can be subjected to pressure maintaining, and therefore, the structural stability of the assembled product is improved.

Owner:SUZHOU RS TECH

A marine environmental protection antifouling coating

ActiveCN102807796BAvoid contamination damageEfficient antifoulingAntifouling/underwater paintsPaints with biocidesEpoxyAcrylic resin

The present invention relates to a coating, in particular to a new type of marine environmental protection antifouling coating, to solve the problem that current marine antifouling coatings are harmful to marine pollution. The new type of marine environmental protection antifouling coating consists of the following components in parts by weight Composition: 10-20 parts of silicone modified acrylic resin, 10-20 parts of water-based acrylic modified epoxy resin, 5-9 parts of hydroxyl-terminated polydimethylsiloxane, 0.5-3 parts of silane coupling agent, organic 17~24 parts of solvent, 22~30 parts of environmental protection antifouling agent, 6~10 parts of zinc oxide, 2~5 parts of talcum powder, 1~3 parts of bentonite, 3~5 parts of iron oxide, 2~5 parts of nano silicon dioxide , 1~3 parts of polytetrafluoroethylene. The new marine environment-friendly antifouling paint of the present invention does not contain organic tin, cuprous oxide and other harmful substances that cause serious harm to the marine ecological environment, and avoids environmental pollution and damage. Achieve high antifouling performance.

Owner:ZHEJIANG MARINE DEV RES INST

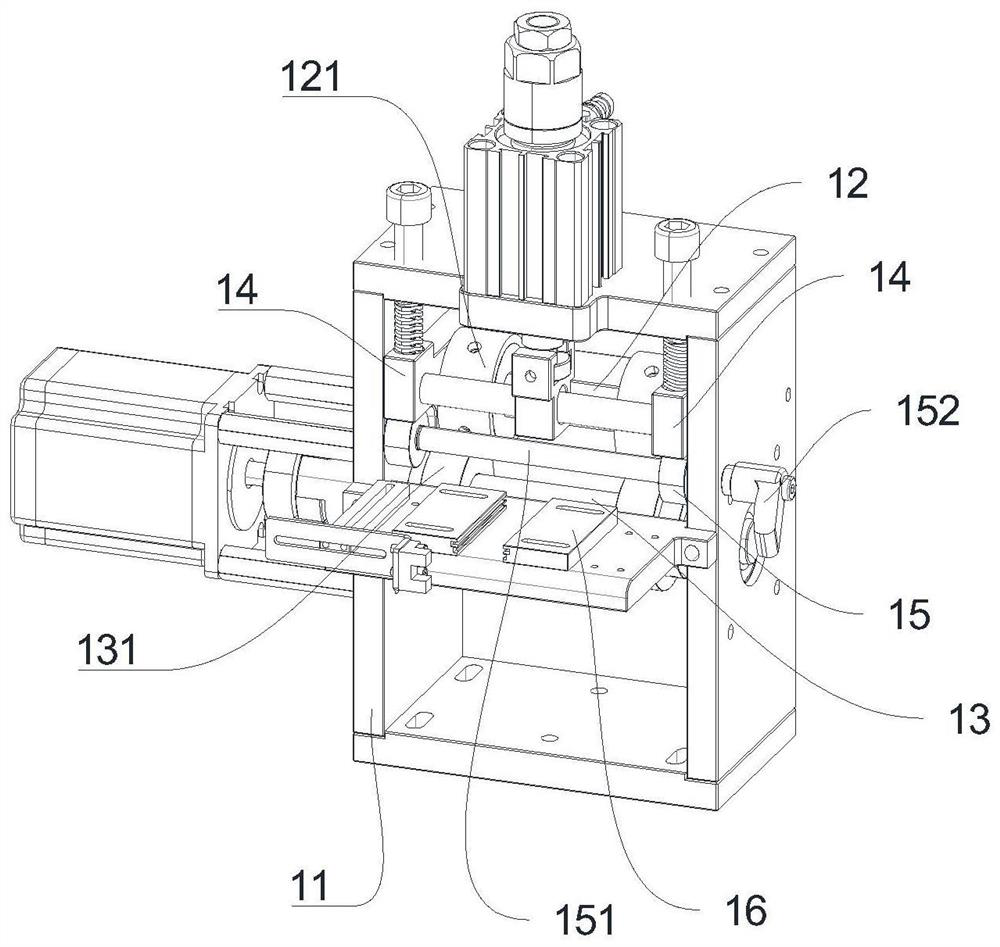

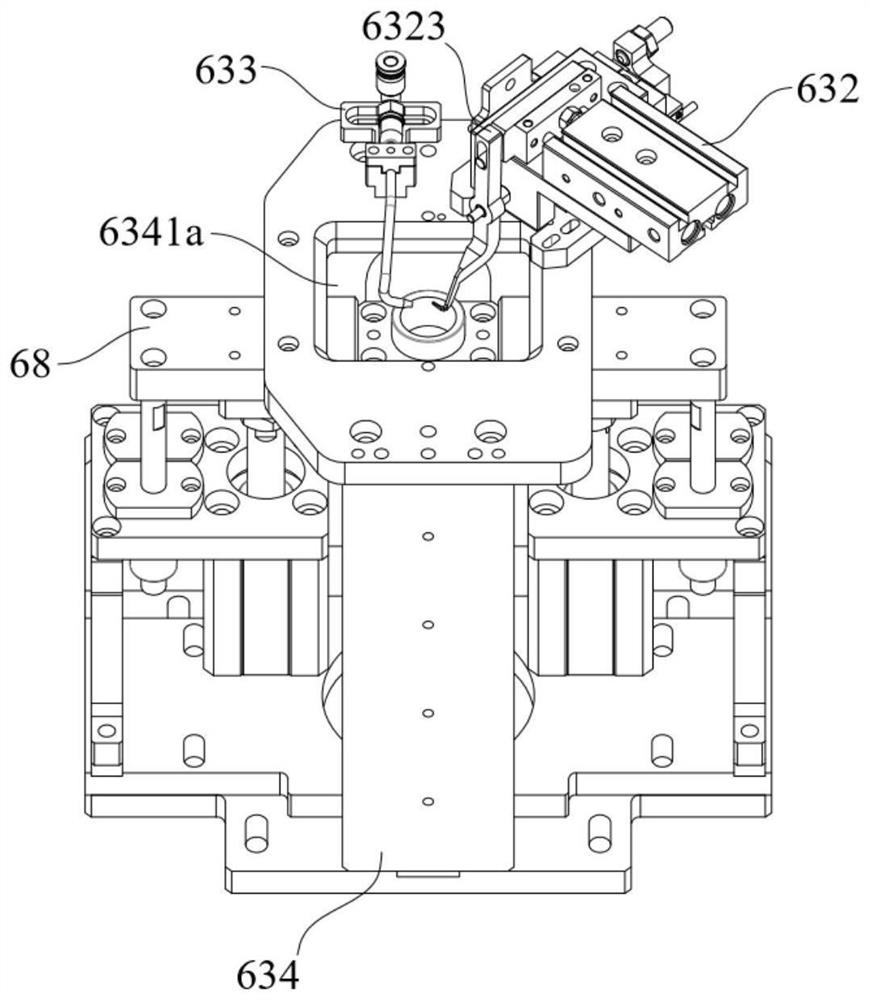

Membrane uncovering mechanism

ActiveCN103558700AAvoid contamination damageSave human effortNon-linear opticsEngineeringMembrane feeding

The invention discloses a membrane uncovering mechanism, relates to the technical field of membrane uncovering and solves the problems that manual membrane uncovering in the prior art causes contamination and damage to membranes, waste manual labor and cannot be better applied to large-scale backlight membranes. According to the embodiment of the invention, the membrane uncovering mechanism comprises a membrane carrying device, a membrane uncovering device, a membrane feeding device and a control device, wherein the membrane carrying device comprises a carrying platform which can be adjusted in position; the membrane uncovering device is located on one side of the carrying platform; the membrane feeding device is arranged opposite to the surface of the carrying platform; the control device can control the membrane carrying device and the membrane feeding device to operate automatically.

Owner:BOE TECH GRP CO LTD +1

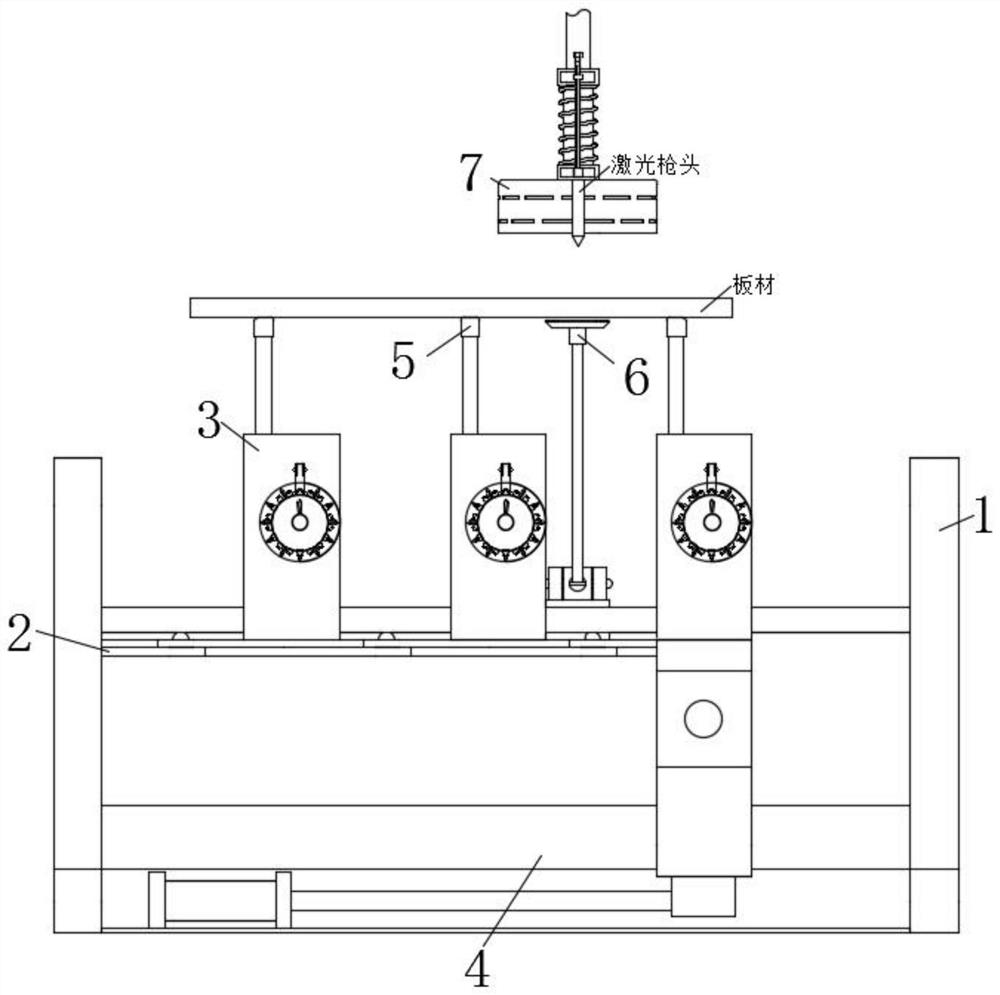

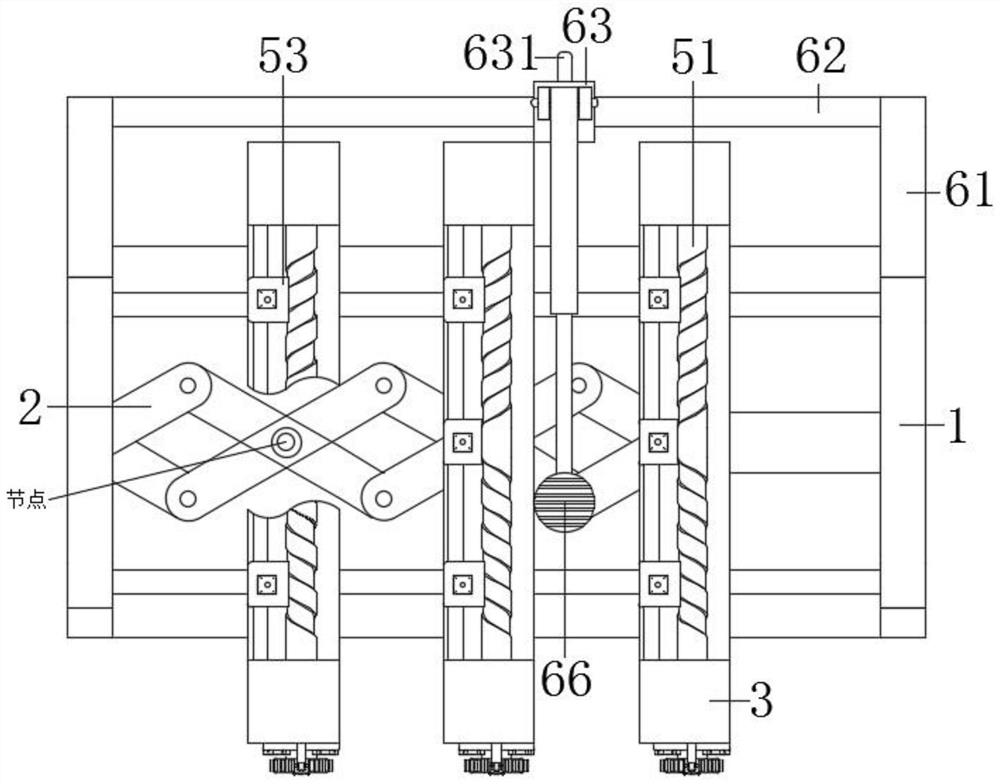

Metal plate laser cutting device and cutting process

InactiveCN113333971AAchieve lateral pitchRealize vertical pitchLaser beam welding apparatusPhysicsEngineering

The invention relates to the technical field of laser cutting, and discloses a metal plate laser cutting device and a cutting process. The metal plate laser cutting device comprises a base, a scissor-fork type telescopic assembly, a movable seat, a transverse spacing adjusting mechanism, a longitudinal spacing adjusting mechanism and a bearing mechanism. The metal plate laser cutting device can solve the problem that a supporting frame is difficult to move integrally in the existing laser cutting technology, the supporting frame is often cut when a workpiece is cut, the structure of the supporting frame is damaged, the supporting effect of the supporting frame is affected, the workpiece can fall off after being machined and collide with excess materials and equipment to be scratched, and the forming effect of the workpiece can be affected; and meanwhile, a current protective cover isolates a human body during laser cutting, but does not isolate the interior of a machine, so that flying chips enter all parts of the machine during working, the using effect of the machine is affected, and then the cutting forming effect is affected.

Owner:武汉天客行知科技有限公司

Method for producing biogas by utilizing anaerobic digestion of livestock excrement

PendingCN112607989AAnaerobic digestion is efficientMake up for the defect of low carbon contentWaste water treatment from animal husbandryWaste based fuelLivestock manureCrop livestock

The invention discloses a method for producing biogas by utilizing anaerobic digestion of livestock excrement, which comprises the following steps: S1, manure pretreatment: collecting livestock excrement, blending an excrement pretreatment solution which comprises bamboo vinegar, plant ash and sterile water in a weight ratio of 1: 1: 10, fully stirring, flushing the excrement by using a high-pressure water gun after the stirring is finished; and the method relates to the technical field of biogas production. According to the method for producing biogas by utilizing anaerobic digestion of livestock manure, the excrement is subjected to sterilization and deodorization pretreatment, so that pollution and damage to crops and soil when the manure is used as an agricultural fertilizer in the later period are avoided, the defect of low carbon content of the manure is overcome by adding fermentation auxiliary materials, and meanwhile, the decomposition and gas production speed of the excrement is further increased; meanwhile, by adding the mixed zymophyte liquid, efficient anaerobic digestion can be conducted on the excrement, and meanwhile the excrement can be converted into organic fertilizer.

Owner:湖北同晟生物能源科技有限公司

Multi-filter-element precision air filter

InactiveCN112325428AImprove filtering effectRealize the function of deodorizationMechanical apparatusLighting and heating apparatusAir filterAir cleaning

The invention discloses a multi-filter-element precision air filter, and particularly relates to the technical field of air purification. The multi-filter-element precision air filter comprises a filter shell and an air inlet, the air inlet is fixedly connected to the middle position of one side of the filter shell, and a noise reduction structure is arranged on the outer side wall of the filter shell. An end cover is arranged in the middle of the other side of the filter shell, an air outlet is fixedly connected to one side of the end cover, a structure convenient to disassemble and clean isarranged between one side of the end cover and one side of the filter shell, and a humidifying mechanism is arranged on one side of the top end in the filter shell. According to the multi-filter-element precision air filter, by arranging scale marks, a water tank, an atomizer and spray heads, during use, the atomizer is turned on, water in the water tank enters the atomizer through a hose, is atomized by the atomizer and then is uniformly sprayed out through the spray heads, filtered air can be humidified, and the indoor air humidity can be kept in summer; and comfort of employees is improved.

Owner:陈锐

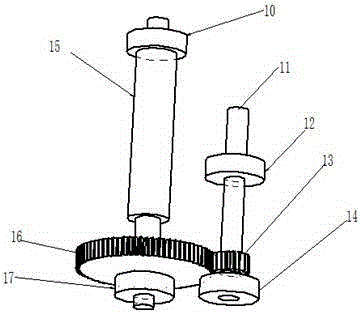

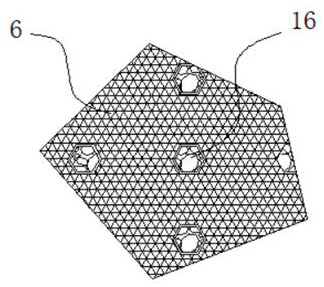

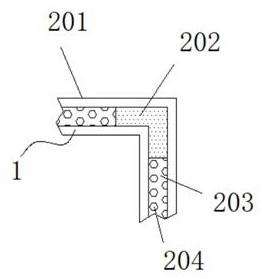

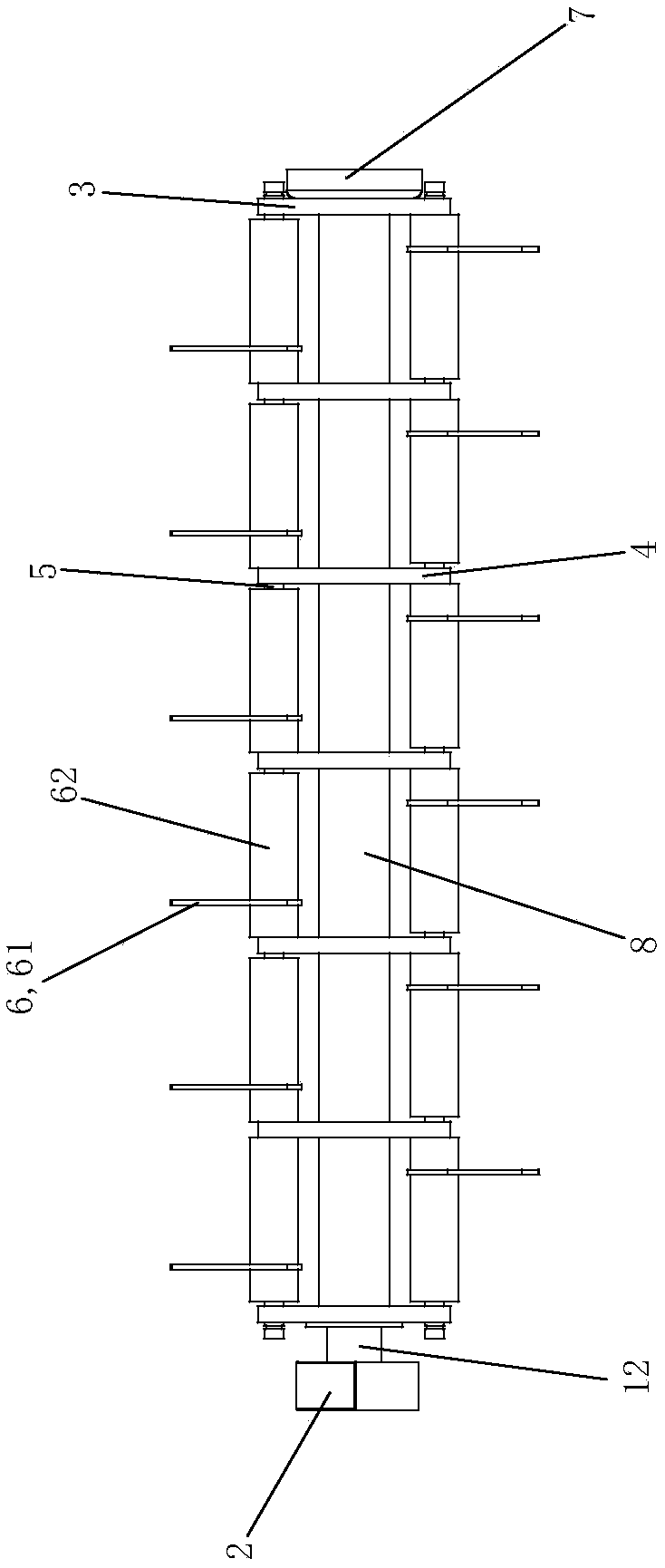

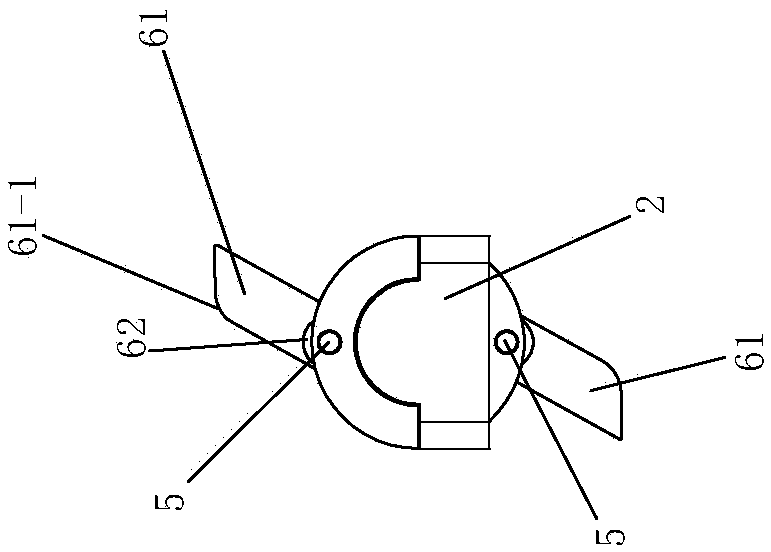

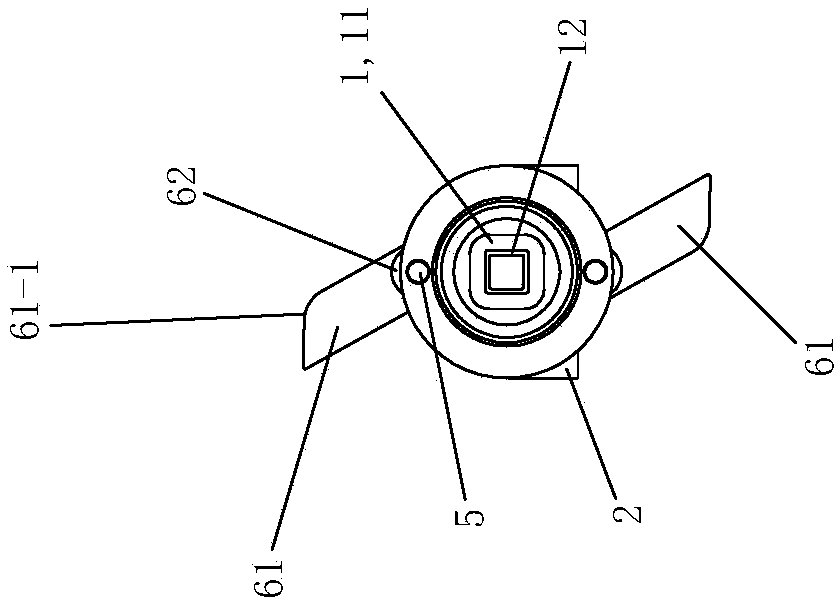

Cutter for lawn ventilator

The invention discloses a cutter for a lawn ventilator. The main points of the cutter provided by the invention are as follows: the cutter comprises a rotating shaft, a hitching leg support, mountingdisks, supporting disks, cutter shafts and blade assemblies; the left end of a short axis of the rotating shaft is rotatably arranged in the hitching leg support through a corresponding bearing; two mounting disks are respectively and fixedly arranged at the left and right ends of a square-tube long axis of the rotating shaft; the supporting disks are arranged on the square-tube long axis of the rotating shaft in a uniformly-spaced manner from left to right; the cutter shafts are arranged on the mounting disks and the supporting disks; each blade assembly comprises a blade and a connecting sleeve; each blade is fixedly embedded on a connecting sleeve; blades are rotatably arranged on the cutter shafts through connecting sleeves; and the blades are spirally arranged in the axial direction of the square-tube long axis of the rotating shaft.

Owner:CHANGZHOU CREATE ELECTRIC APPLIANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com