Integrated wide-light-spot deep-hole laser cladding head

A laser cladding and integrated technology, which is applied in the direction of metal material coating process, coating, energy efficiency improvement, etc., can solve the problems of high integration and small size, and achieve the effect of preventing pollution damage and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings, so that those skilled in the art can understand the present invention more clearly, but the protection scope of the present invention is not limited thereby.

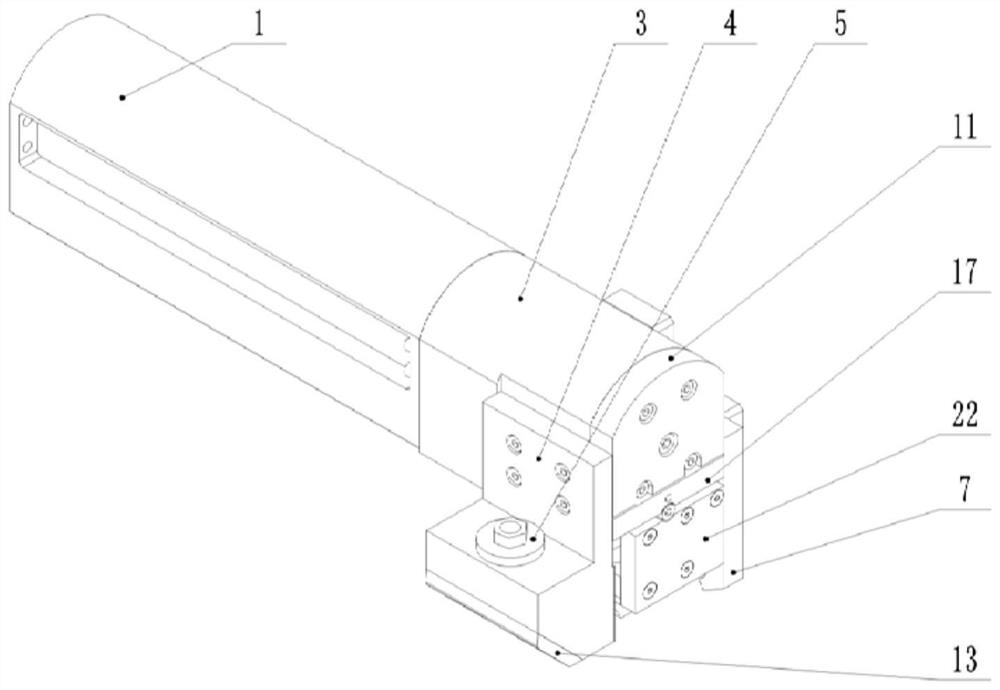

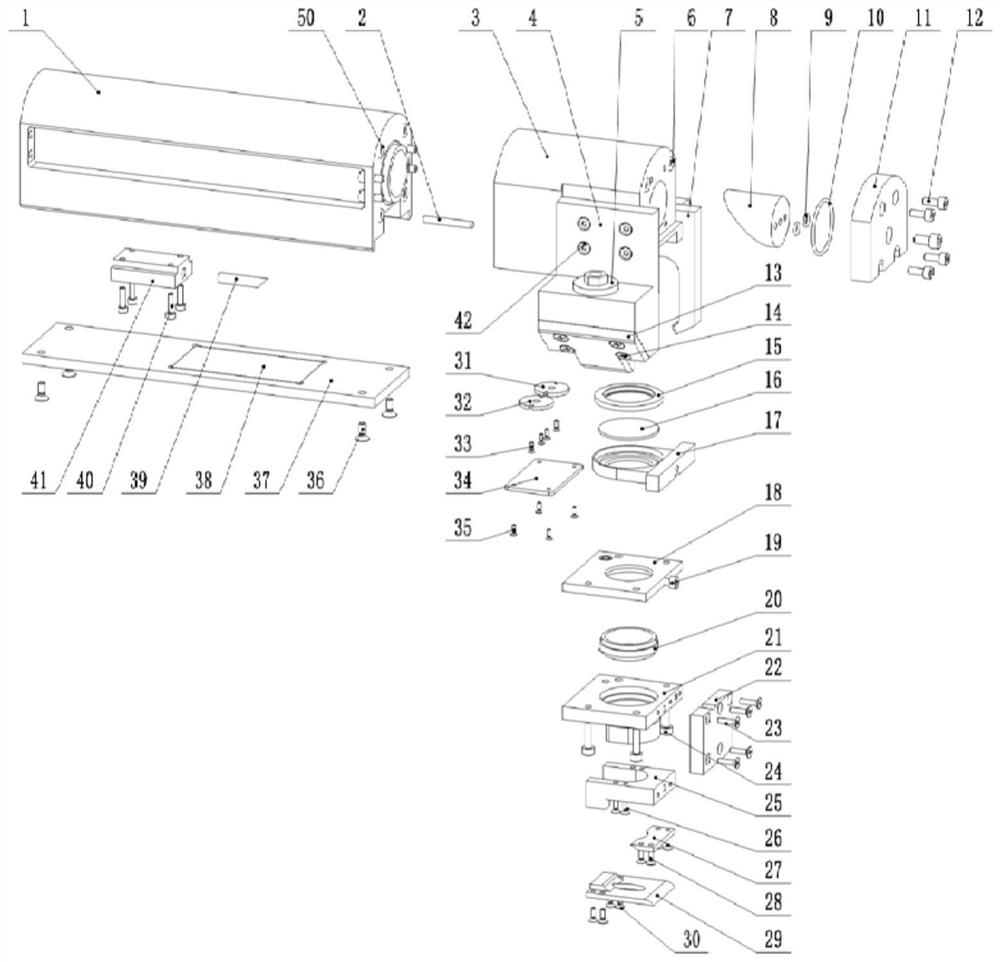

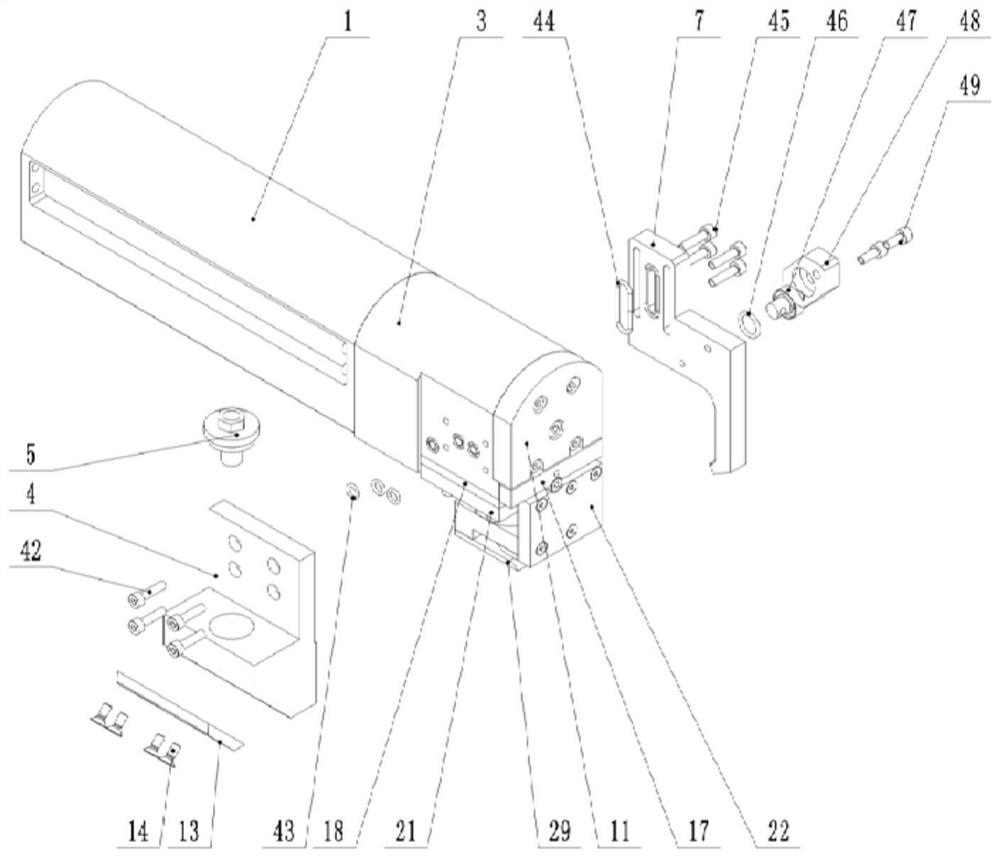

[0038] The present invention proposes an integrated wide-spot deep-hole laser cladding head, as attached Figure 1-10 As shown, it includes: connecting rod 1, temperature sensor 2, fixing seat 3, powder feeding head 4, powder gas separator cover 5, sealing ring 6, cleaning bracket 7, integrating reflector 8, sealing ring 9, sealing ring 10, Integral mirror base 11, screw 12, powder feeding plate 13, screw 14, protective mirror sealing ring 15, protective lens 16, protective mirror drawer 17, guide ring cover 18, screw 19, guide ring 20, guide cover 21 , shunt 22, screw 23, screw 24, air knife deflector 25, screw 26, air knife cover 27, screw 28, light baffle 29, screw 30, lighting 31, lighting 32, screw 33, glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com