Wind tunnel test device of windscreen wiper pressing force distribution and windscreen wiper controlling method

A test device and technology of wiper, which is applied in the direction of measurement device, machine/structural component test, fluid pressure measurement by changing ohmic resistance, etc. It can solve problems such as detachment, impact on vehicle safety, and different pressing force of wiper, etc., to achieve Avoid water waste, strong rigidity, and small flow field disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below with reference to the accompanying drawings, so that those skilled in the art can implement it with reference to the text of the description.

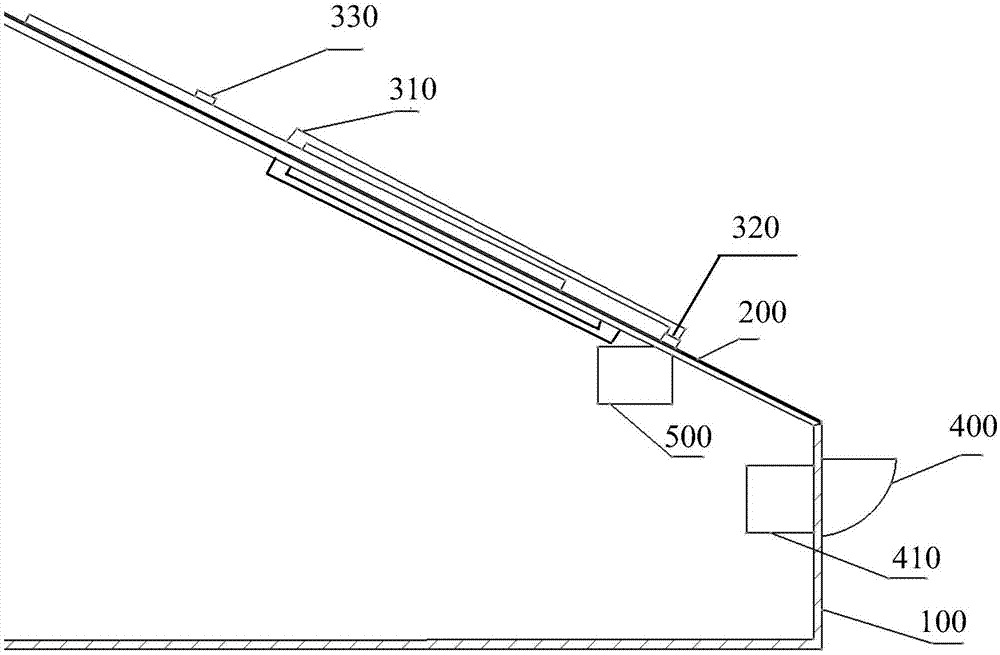

[0048] Such as figure 1 As shown, the wind tunnel test device for wiper compression force distribution provided by the present invention includes: a support frame 100, a laminated glass 200, a wiper 300 and a water tank 400.

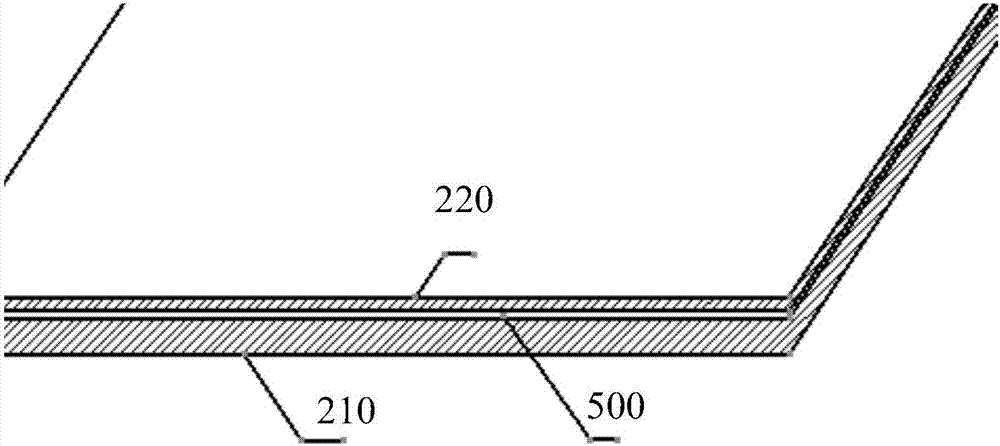

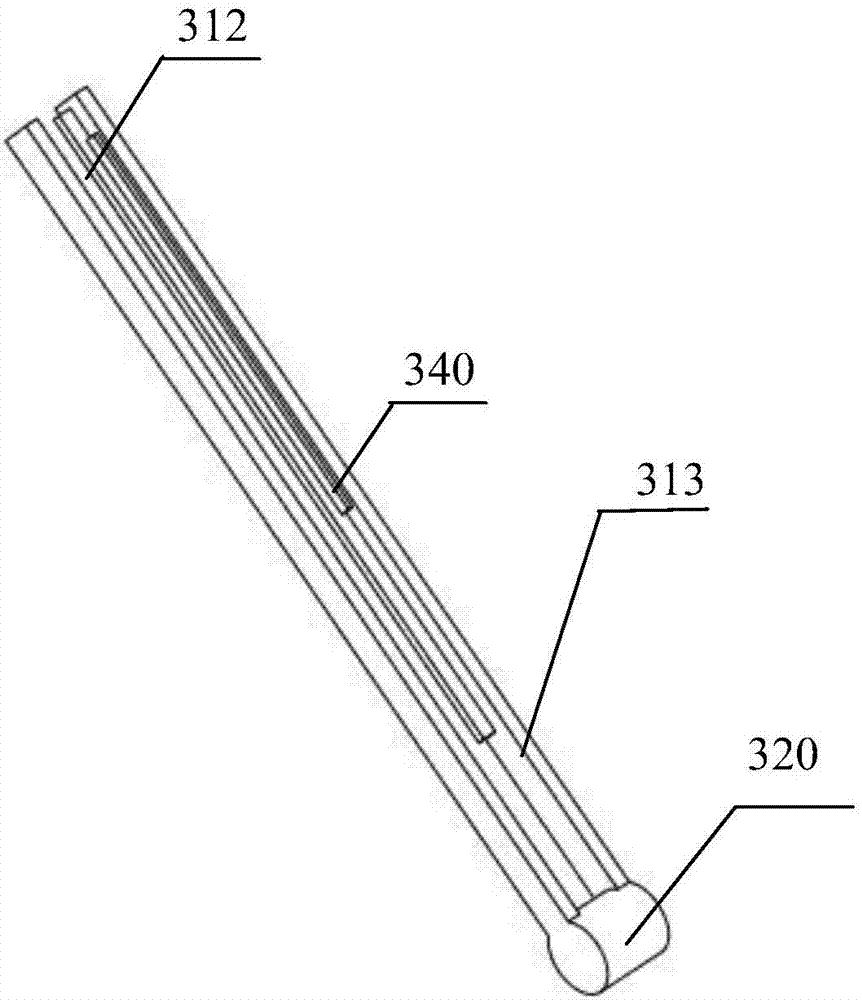

[0049] Wherein, the top of the support frame 100 is provided with a laminated glass 200, which includes an outer glass layer 210 and an inner glass 220; the wiper blade 300 is arranged on the outside of the laminated glass 200, including a wiper arm 310 which is attached to the outer glass layer The surface; the rotating shaft 320, which is set at one end of the wiper arm 310, the wiper arm 310 can rotate around the rotating shaft 320; the water spray port 330, which is set on the other end of the wiper arm 310; the water tank 400, which is set at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com