Double-layer film material aligning and lamination assembly line

A technology of alignment lamination and double-layer film, applied in lamination, lamination device, lamination auxiliary operation, etc., can solve problems such as difficulty in guaranteeing product quality, increased pollution risk, high labor intensity, etc., and achieve shortening of exposure Time outside, improvement of yield rate and production efficiency, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

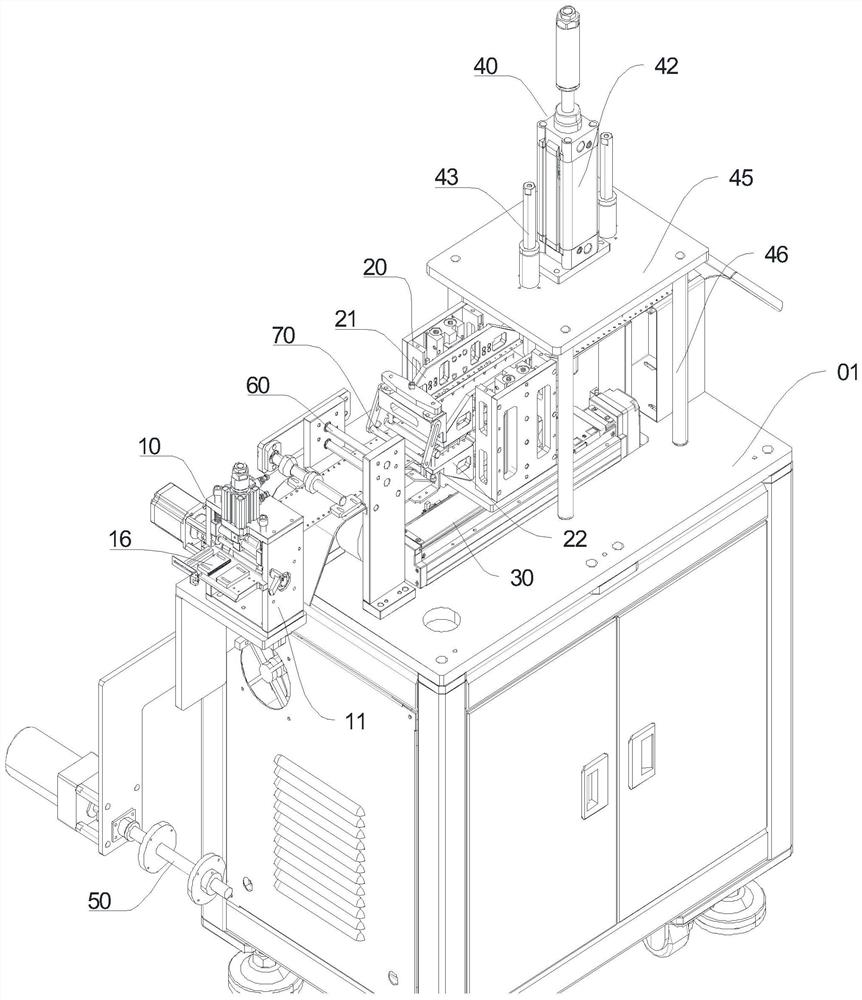

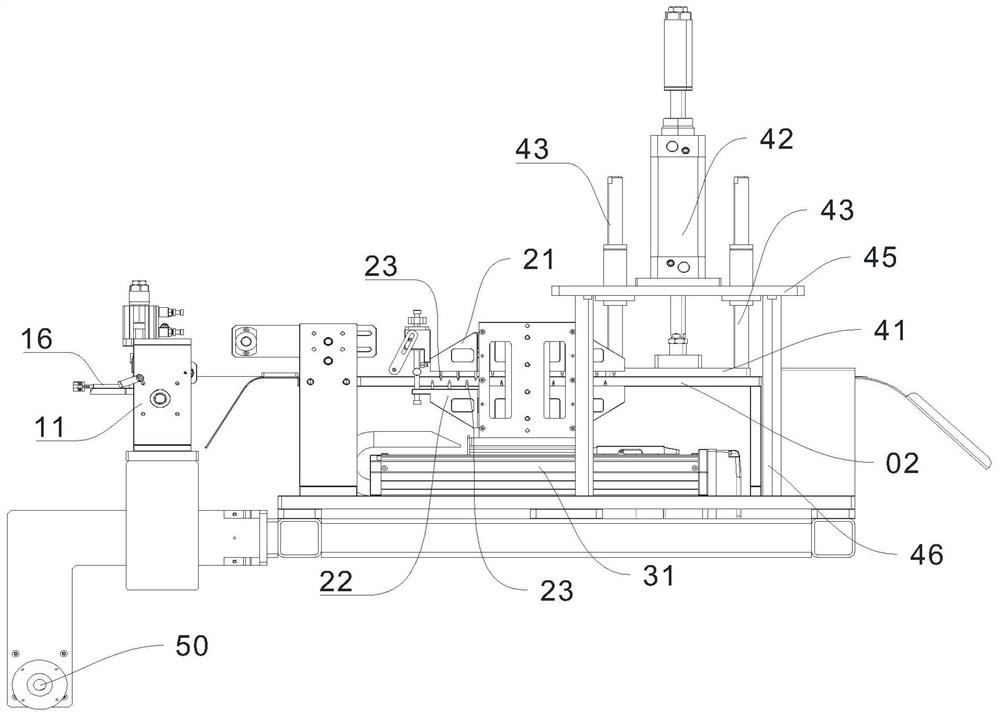

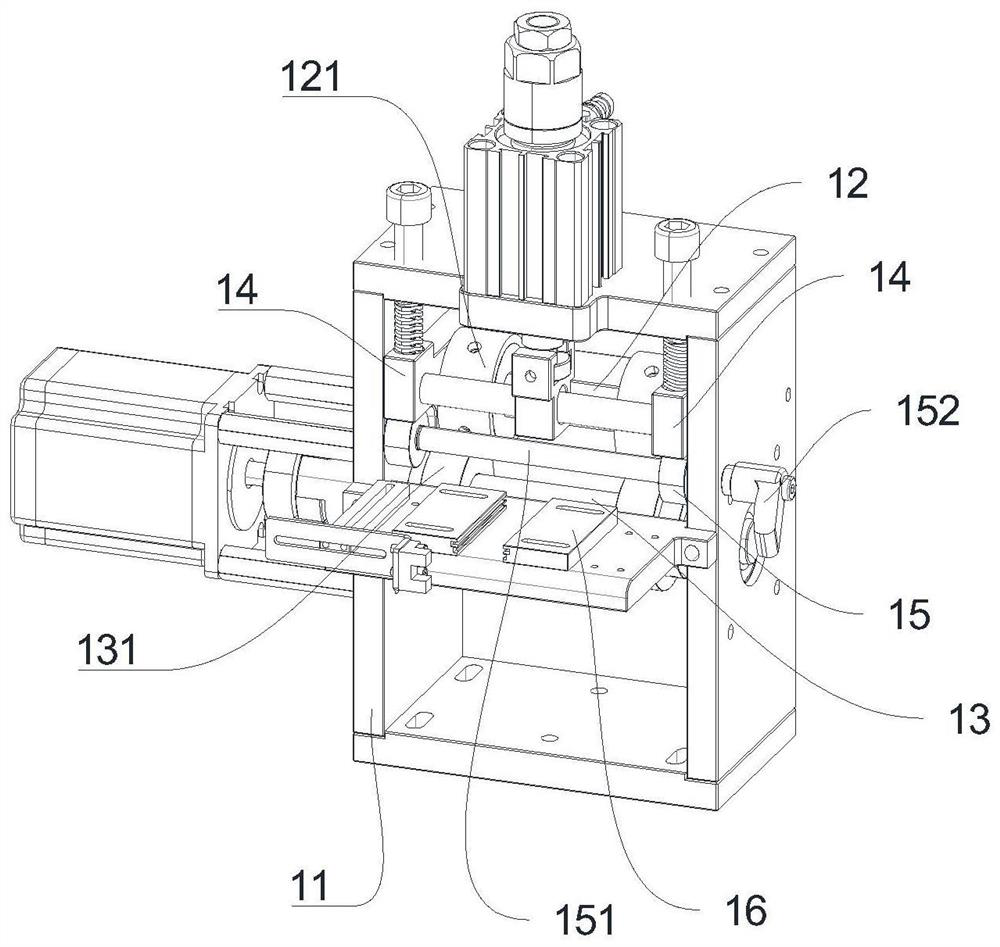

[0027] Figure 1 to Figure 9 Schematically shows a double-layer film material alignment lamination line according to an embodiment of the present invention. Such as figure 1 and figure 2 As shown, the device includes a frame 01, on which the waste collection module 10, alignment module 20, and pressing module 40 are sequentially connected along the X direction, and a drawing die is also arranged below the alignment module 20 Group 30 : one side of the waste collection module 10 close to the alignment module 20 is provided with one upper and one lower guide rollers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com