Multi-filter-element precision air filter

An air filter and filter technology, applied in the field of air purification, can solve the problems of inability to meet the needs of use, poor filtering effect, and no deodorization, and achieve the effects of avoiding air drying, facilitating disassembly and cleaning, and improving comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

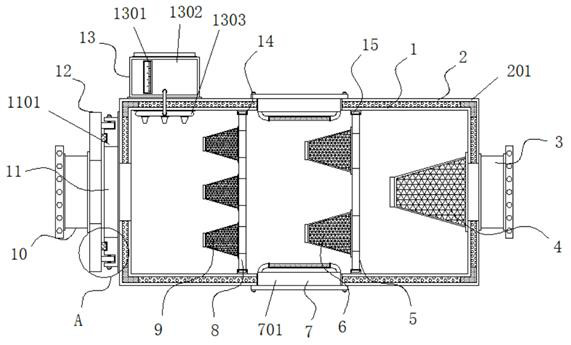

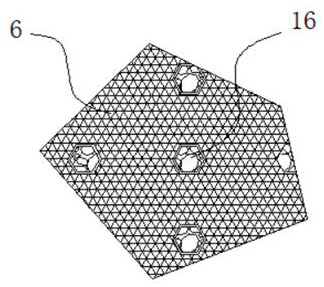

[0035] Example 1: See Figure 1-6 , a multi-filter precision air filter, comprising a filter housing 1 and an air inlet 3, the air inlet 3 is fixedly connected at the middle position on one side of the filter housing 1, and the outer wall of the filter housing 1 is provided with a noise reduction structure 2. An end cover 12 is provided at the middle position on the other side of the filter housing 1, and one side of the end cover 12 is fixedly connected with an air outlet 10, and a side of the end cover 12 and one side of the filter housing 1 are provided with a It is convenient to disassemble and clean the structure 11. One side of the inner top of the filter housing 1 is provided with a humidifying mechanism 13. The top and bottom of the inner filter housing 1 are respectively provided with an ultraviolet sterilizing mechanism 7. One side of the filter housing 1 is fixedly connected with a The primary filter element 4 and the interior of the filter housing 1 are provided wi...

Embodiment 2

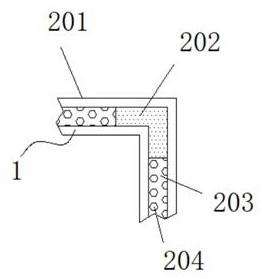

[0040] Embodiment 2: Noise reduction structure 2 is made up of shell 201, connection block 202, cavity 203 and soundproof cotton 204, and connection block 202 is fixedly connected at the four corners outside filter housing 1, and the outer end of connection block 202 is fixedly connected There is a housing 201, a cavity 203 is provided between the housing 201 and the filter housing 1, and the interior of the cavity 203 is filled with soundproof cotton 204;

[0041] Specifically, such as figure 1 with image 3 As shown, when in use, the sound insulation performance of the sound insulation cotton 204 is used, so that the noise generated by the impact force of the air will be greatly reduced when the air passes through the inside of the filter housing 1, thereby avoiding the air filter. Noise pollution is generated during work and the indoor environment is protected.

Embodiment 3

[0042] Embodiment 3: The ultraviolet sterilizing mechanism 7 is composed of a lamp holder 701, a fixed plate 702, a fixed frame 703, an ultraviolet germicidal lamp 704 and a fixing bolt 705. The lamp holder 701 is embedded in the middle position of the filter housing 1 respectively, and the lamp holder 701 A fixed plate 702 is fixedly connected to one end of the fixed plate 702, fixed bolts 705 are arranged on both sides of the fixed plate 702, fixed frames 703 are fixedly connected to both sides of the bottom of the lamp holder 701, and ultraviolet germicidal lamps 704 are fixedly connected between the fixed frames 703. The model of lamp 704 can be E27-lamp tube;

[0043] The lamp holder 701 penetrates to the inside of the filter housing 1, and the width of the fixing plate 702 is greater than the width of the lamp holder 701;

[0044] Specifically, such as figure 1 with Figure 4 As shown, when in use, the lamp holder 701 is energized, so that the ultraviolet germicidal la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com