Method for recycling waste gas generated by rare earth electrolyzed by fluoride system

A waste gas recovery and fluoride technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of increasing environmental protection pressure, waste of fluorine resources, and complicated treatment processes, and achieves low requirements for equipment and saves The cost of raw materials and the effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

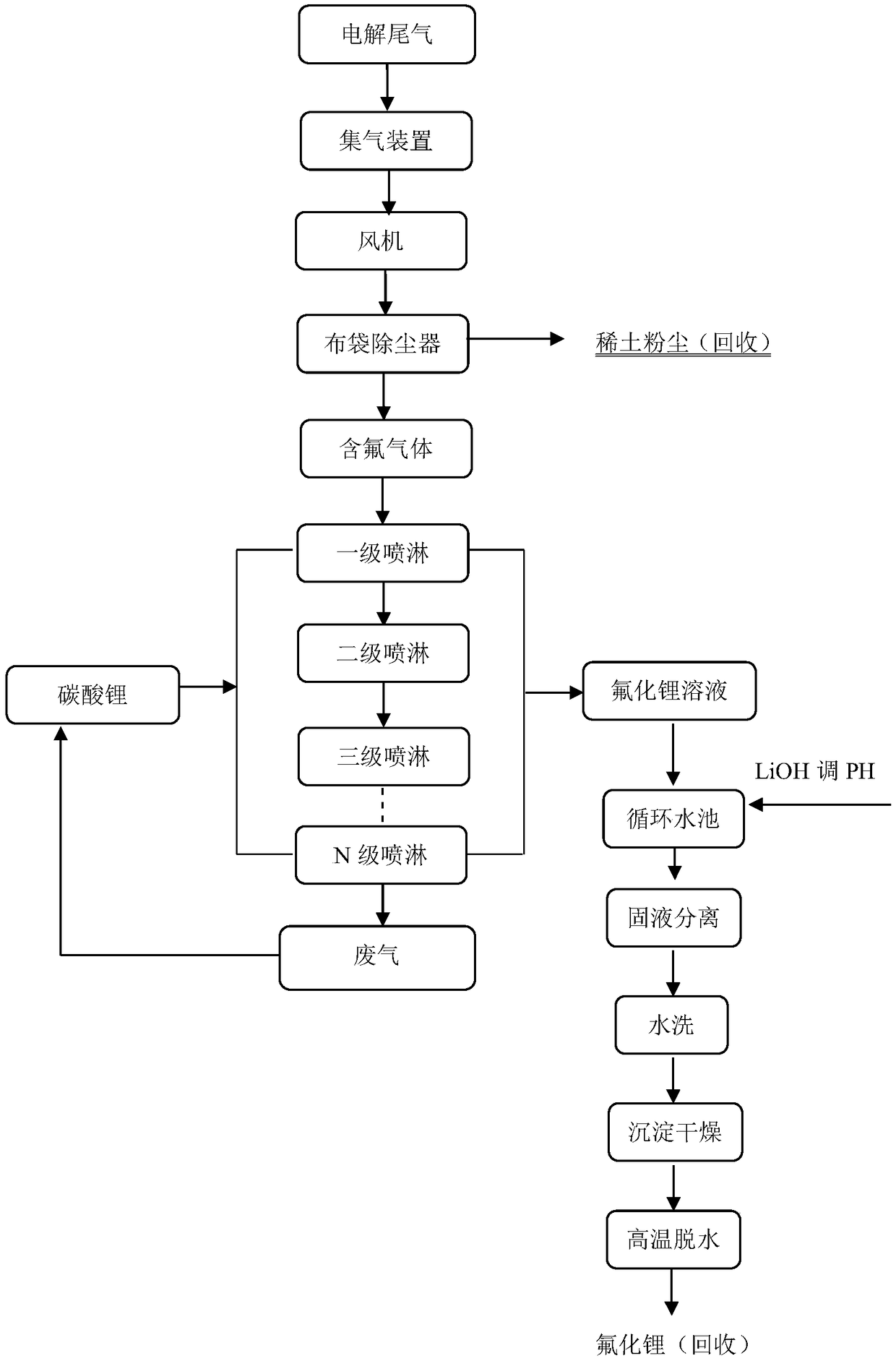

Method used

Image

Examples

Embodiment 1

[0035] Invest 1 from May 8 #100 kg of lithium carbonate in No. Circulating Absorption Tower, 50 kg was added for the second time on May 21, lithium fluoride was collected on May 27, the lithium fluoride solution was put into the circulating water pool, and the pH was adjusted to 3 by lithium hydroxide. PH to 6.5 after liquid separation and water washing for 3 times, drying at 110°C for 3 hours, and dehydration at 450°C for 3 hours to obtain 50.36 kg of lithium fluoride, and the calculated comprehensive yield in 7 days was 41.67% (only a single addition of lithium carbonate was calculated) The yield, containing lithium hydroxide, the same below), the lithium fluoride obtained is detected, and its composition is as shown in table 1;

[0036] Table 1 Lithium fluoride composition analysis

[0037] Test items

Embodiment 2

[0039] Add 200 kg of lithium carbonate on May 27th, recover lithium fluoride on June 26th, adjust pH to 3 with lithium hydroxide, separate solid-liquid, wash with water for 4 times, then PH to 7, dry at 110°C for 5 hours, and heat at 420°C After dehydration for 9 hours, 130.28 kg of lithium fluoride was obtained, with a comprehensive yield of 84.50%;

Embodiment 3

[0041] Put 200 kg of lithium carbonate on June 26, collect lithium fluoride on July 25, adjust the pH to 3 with lithium hydroxide, separate the solid and liquid, and wash with water for 3 times. After dehydration for 7 hours, 147.28 kg of lithium fluoride was obtained, with a comprehensive yield of 96.04%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com