Extractor hood

A range hood and casing technology, which is applied in the field of range hoods with sterilization and purification functions, can solve the problems of short circuit of the ozone generator circuit, affect the effect of sterilization and purification, damage the ozone generator, etc., and achieve uniform ozone concentration, ozone The effect of concentration dynamic balance and avoiding uneven concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

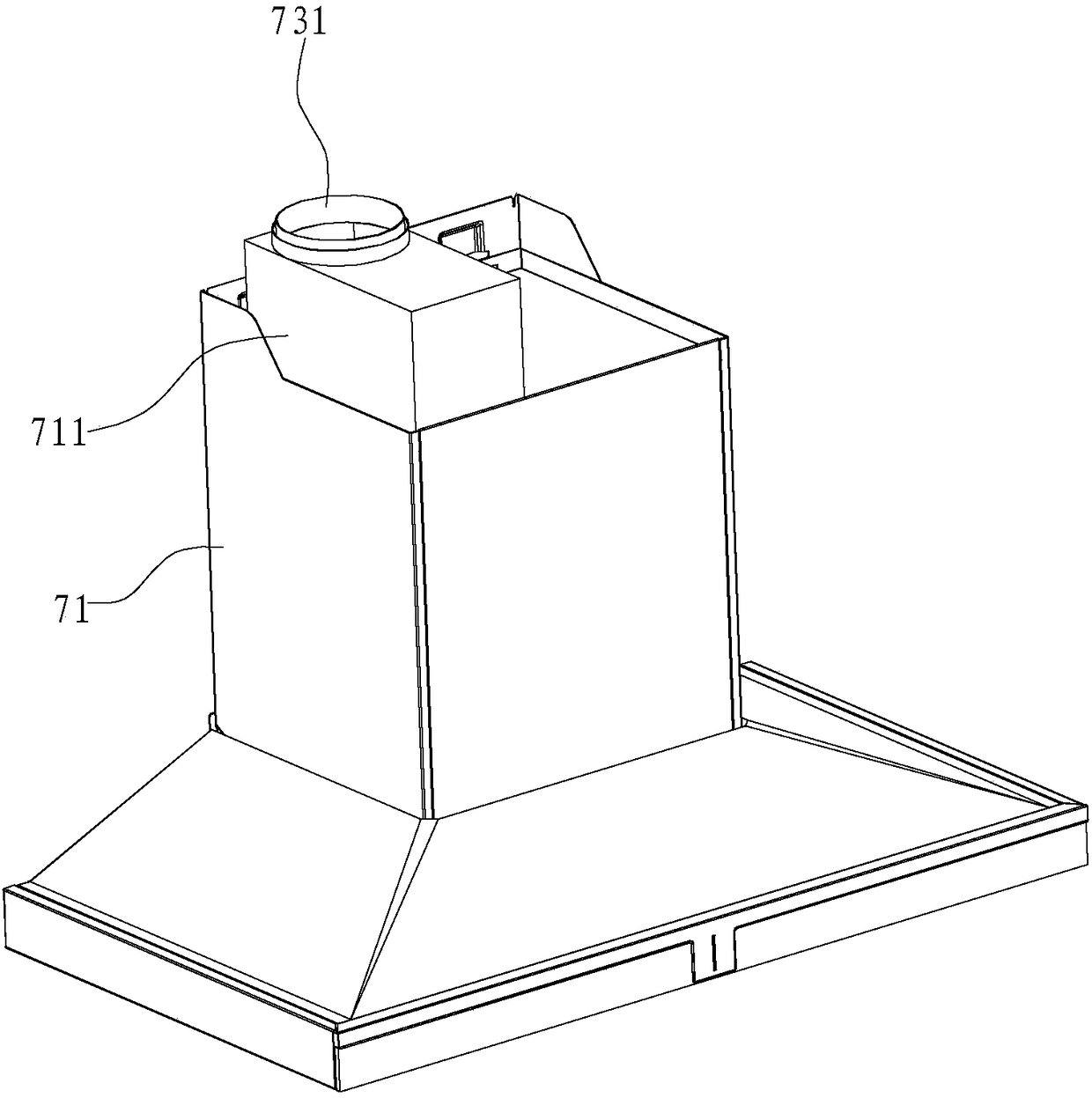

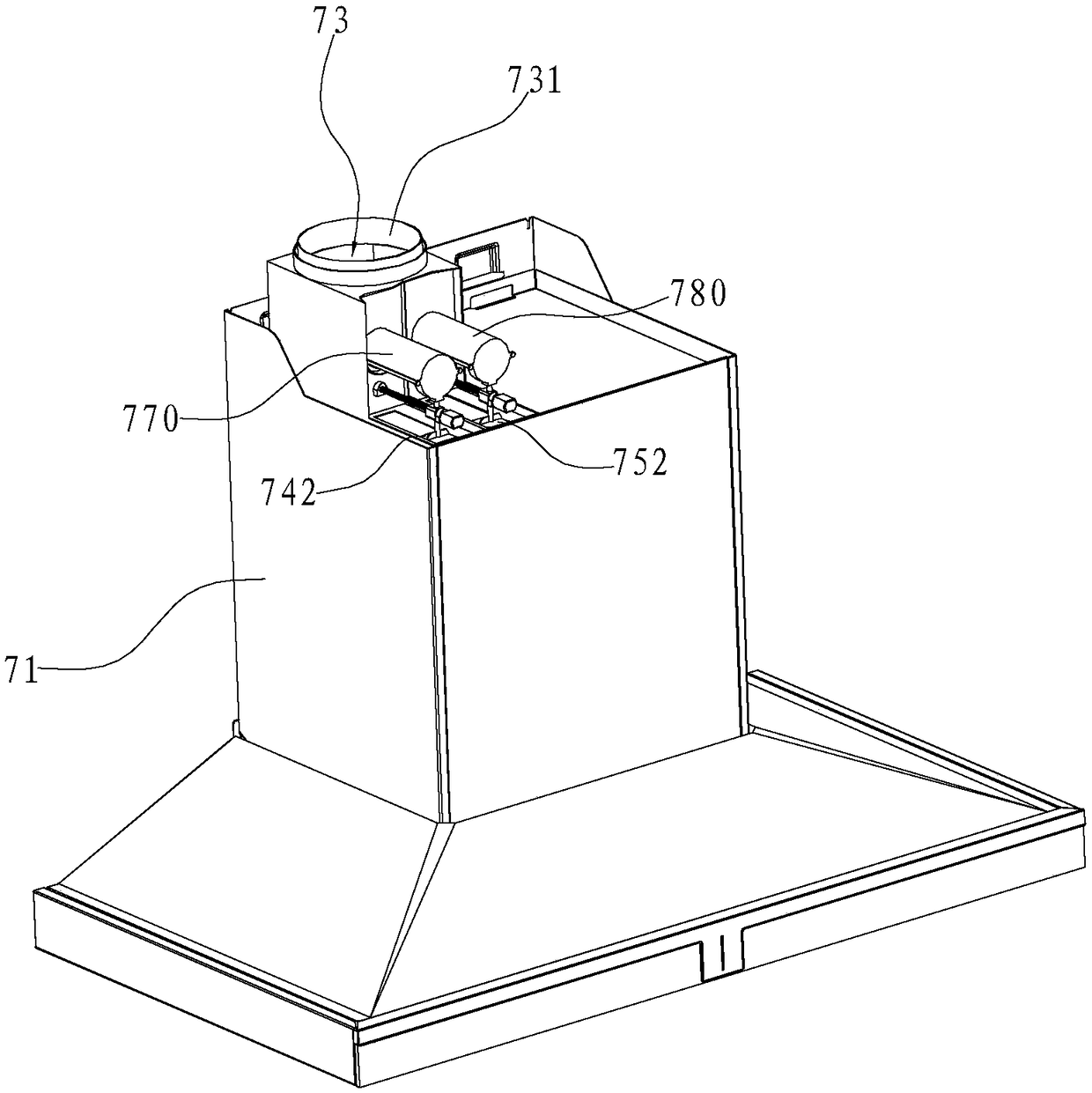

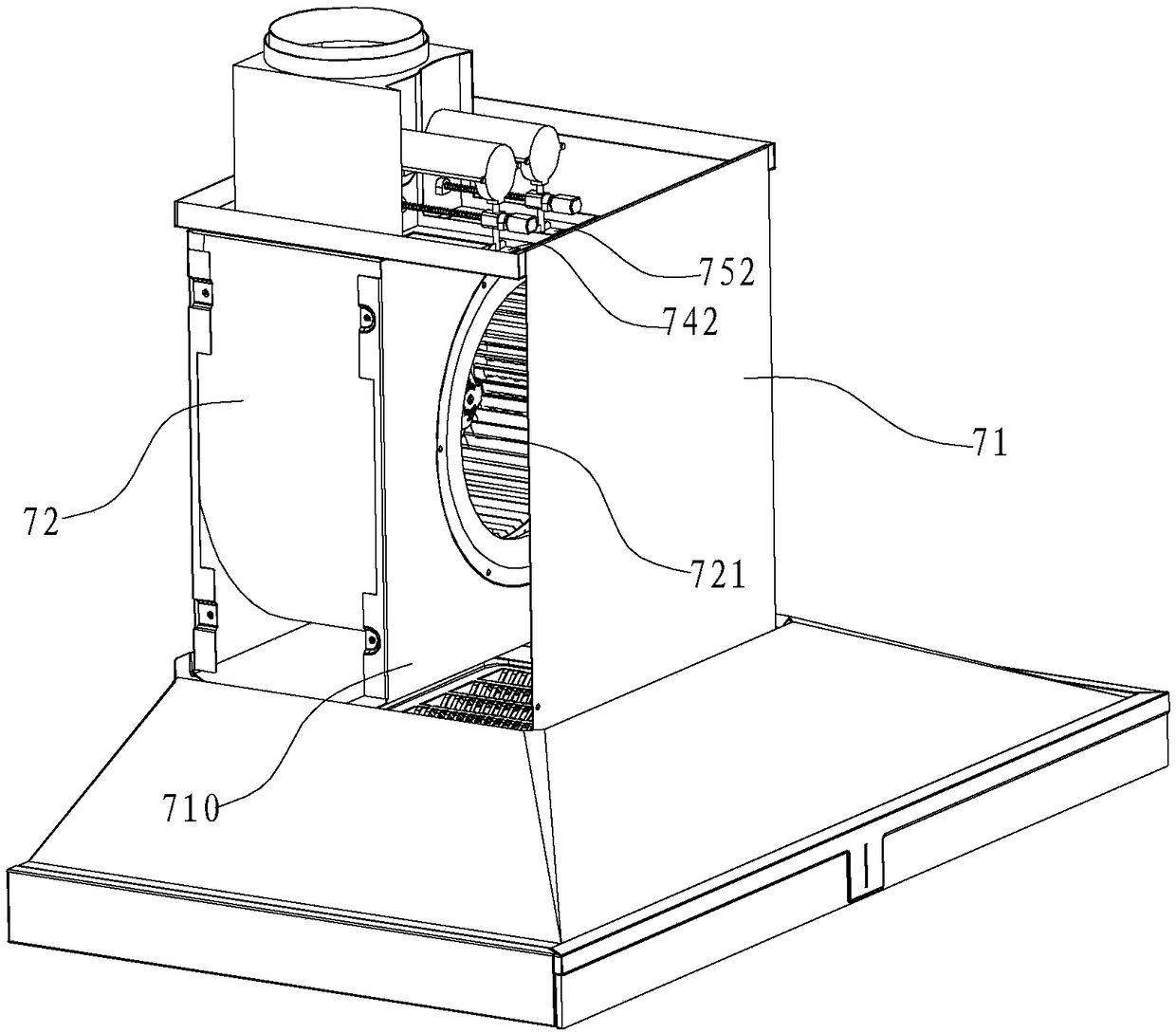

[0037] Such as Figure 1-10 As shown, a range hood includes a casing 71 with an inner cavity 710 and an air outlet cover 711, the inner cavity 710 is provided with a fan 72, the above air outlet cover 711 is provided with an air outlet cavity 73, and the outlet The air chamber 73 is located above the inner chamber 710 and communicates with the inner chamber 710 through the air inlet 736. The top of the air outlet chamber 73 has an air outlet 731, and the air outlet 731 is provided with an air outlet valve plate capable of opening and closing the air outlet 731. (not shown, the air outlet valve plate can adopt a conventional structure in the prior art).

[0038] The air outlet hood 711 is also provided with a purification chamber 74 and a heating chamber 75 , which are arranged in parallel with the air outlet chamber 73 respectively, and all three are located above the inner chamber 710 . The purification chamber 74 has a vertically extending first side wall 732 shared with th...

Embodiment 2

[0047] Such as Figure 11 with Figure 12 As shown, the difference from Embodiment 1 is that in this embodiment, both the first mounting base 770 and the second mounting base 780 include a cylindrical cover body, and circular end caps are respectively fixed on both ends of the cover body. . The end cover of the first mounting base 770 adjacent to the first air inlet 733 (the end face of the end cover is the above-mentioned 7701) matches the first air inlet 733, and the end cover of the second mounting base 780 adjacent to the second air inlet 735 The end cover (the end face of the end cover is the above-mentioned 7801 ) is matched with the above-mentioned second air inlet 735 . The above-mentioned sterilizing device 77 and heating device 78 are respectively installed in the first mounting base 770 and the second mounting base 780, and the two ends of the first mounting base 770 are respectively provided with first ventilation holes 7703, and the first ventilation holes 7703 ...

Embodiment 3

[0049] Such as Figures 13 to 17As shown, the difference from Embodiment 1 is that in this embodiment, the purification chamber 74 and the heating chamber 75 are arranged side by side, and the air outlet chamber 73 is provided on one side of the two, and the air outlet chamber 76 is provided on the other side. The air outlet chamber 76 has a vertical side wall 762 common to the purification chamber 74 and the heating chamber 75 . The above-mentioned first air outlet 741 and second air outlet 751 have the same structure and are arranged in the air outlet chamber 76, that is, the air outlet 761 opened on the bottom wall of the air outlet chamber 76, and the air outlet is also located at the air inlet of the fan 72. above port 721. The purification chamber 74 and the heating chamber 75 communicate with the air outlet chamber 76 through the first vent hole 7621 and the second vent hole 7622 respectively, and the first vent hole 7621 and the second vent hole 7622 are set on the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com