Soot filter and extractor hood with soot filter

A technology of oil fume filtration and range hoods, which is applied in the application, removal of oil fume, household stoves, etc. It can solve the problems of the limitation of sterilization and deodorization functions, affect the effect of sterilization and purification, and damage the ozone generator, so as to avoid the occurrence of oil fume pollution and ozone device effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

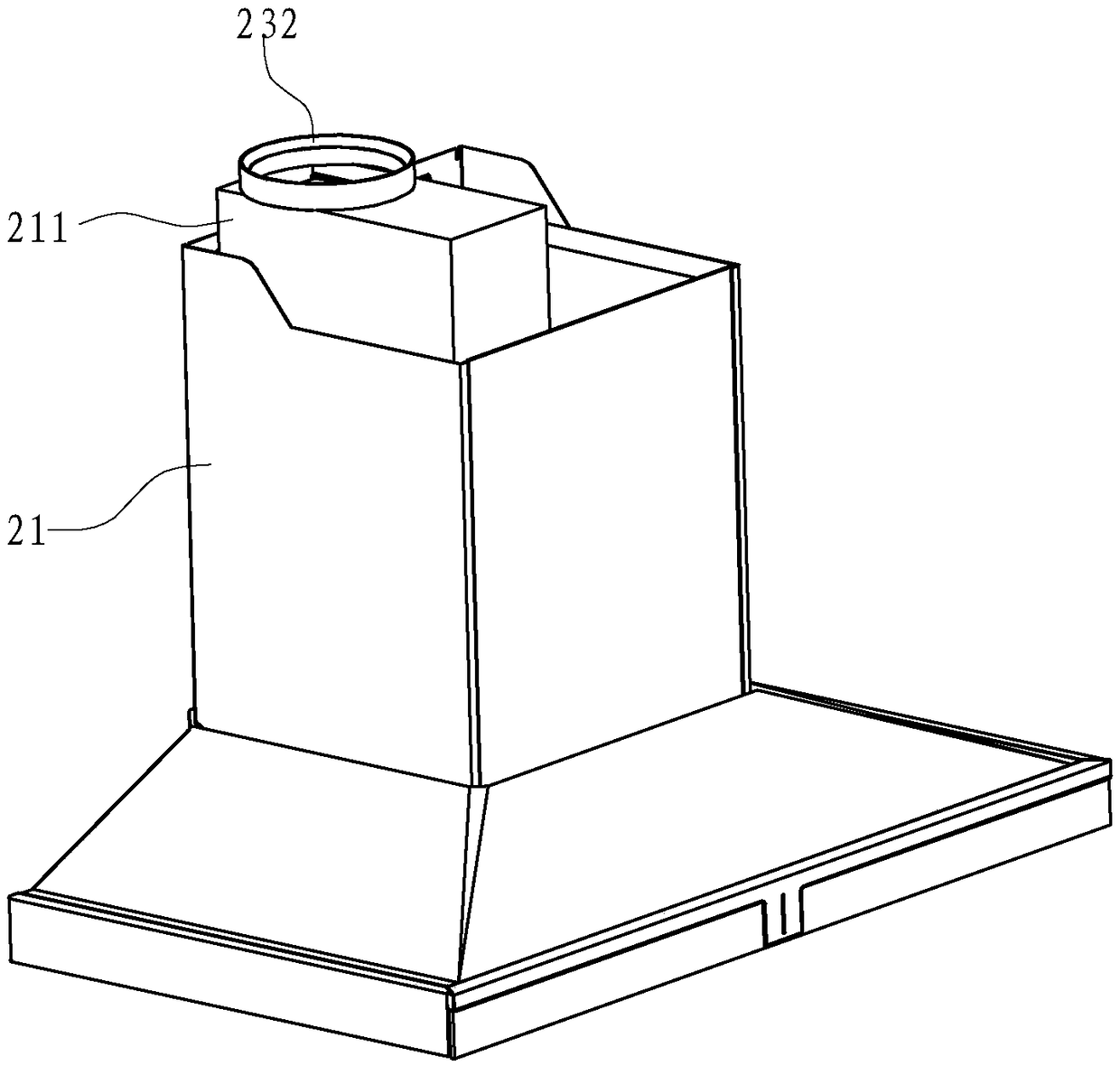

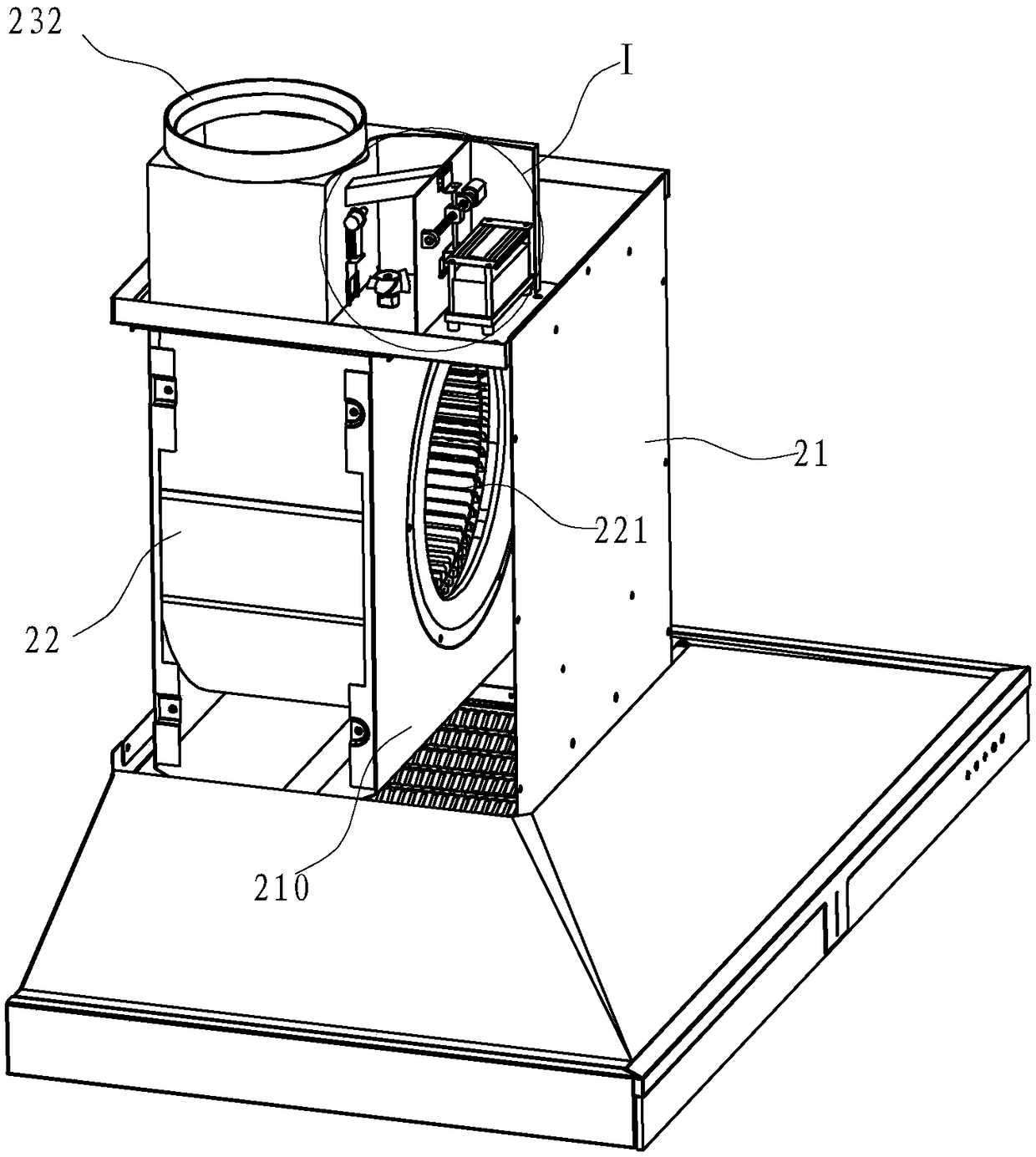

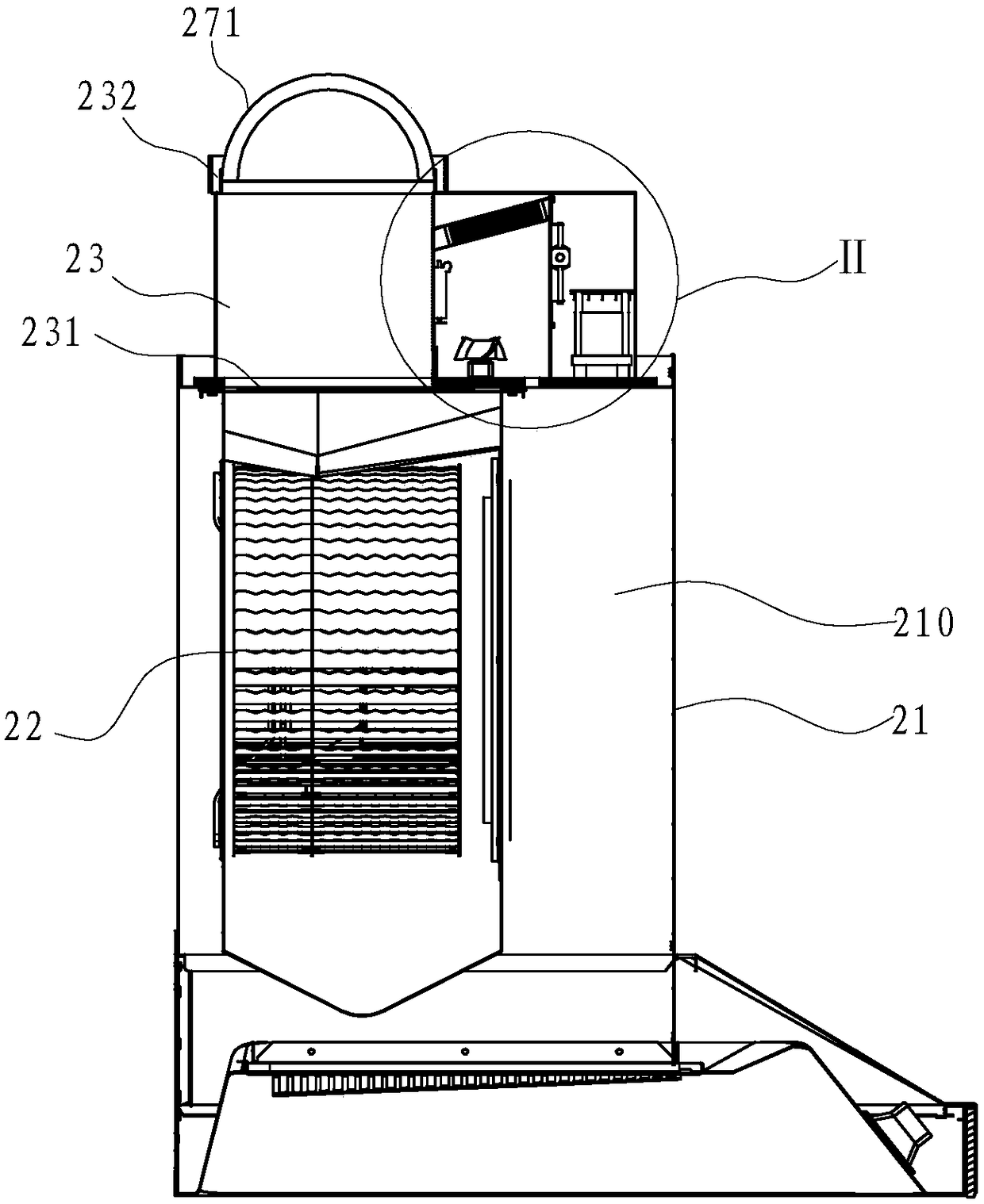

[0032] Such as Figure 1-9As shown, a range hood includes a casing 21 with an inner cavity 210 and an air outlet cover 211, the inner cavity 210 is provided with a fan 22, the above air outlet cover 211 is provided with an air outlet cavity 23, and the outlet The air chamber 23 is located above the inner chamber 210 and communicates with the inner chamber 210 through the air inlet 231. The top of the air outlet chamber 23 has an air outlet 232, and the air outlet 232 is provided with an air outlet valve plate capable of opening and closing the air outlet 232. 271.

[0033] Further, the air outlet hood 211 is also provided with a clean chamber 24 and a mixing chamber 25 , the clean chamber 24 is provided with an ozone generator 26 , and the mixing chamber 25 is provided with a mixer 202 . Above-mentioned purification chamber 24 and mixing cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com