A kind of preparation method for the polyalcohol of flame-retardant polyurethane foam plastics

A technology of foamed plastics and polyurethane, which is applied in the fields of polymer chemistry, building insulation materials, and reactive flame retardants. The effect of mild operation and preparation reaction and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

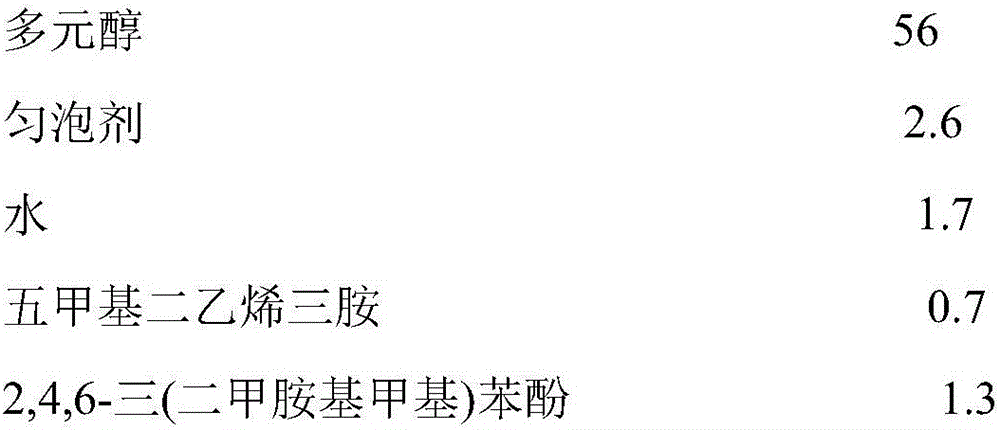

Examples

Embodiment 1

[0039] Embodiment 1 A kind of preparation method for the polyol of flame-retardant polyurethane foam plastics

[0040] Add 100 g of triethyl phosphate into a flask equipped with a reflux device, start stirring, add 40 g of phosphorus pentoxide, heat it up to 120°C, and keep it warm for 20 min; add 40 g of pentaerythritol and 1.5 g of catalyst monobutyl stannic acid, and react h; add ethylene oxide 250g and catalyst tetraethylammonium bromide 1.6g, continue to react for 5 h, cool, and discharge; the product obtained is a light yellow transparent liquid with an acid value of 1.9 mgKOH / g and a viscosity of 7583 mPa. s.

Embodiment 2

[0041] Embodiment 2 A kind of preparation method for the polyol of flame-retardant polyurethane foam plastics

[0042] Add 100g of triethyl phosphate into the flask equipped with a reflux device, start stirring, add 80g of phosphorus pentoxide, heat up to 125°C, and keep it warm for 30 minutes; add 60g of pentaerythritol and catalyst monobutyl dihydroxytin chloride 1.8g, reacted for 3.5 h; added 320g of epichlorohydrin and 2.2g of catalyst dodecyltrimethylammonium chloride, continued to react for 5h, cooled, and discharged; the obtained product was a light yellow transparent liquid with an acid value of 1.6 mgKOH / g, the viscosity is 8720 mPa.s.

Embodiment 3

[0043] Embodiment 3 A kind of preparation method for the polyol of flame-retardant polyurethane foam plastics

[0044]Add 100g of triethyl phosphate into the flask equipped with a reflux device, start stirring, add 60g of phosphorus pentoxide, heat up to 120°C, and keep it warm for 25 minutes; add 50g of pentaerythritol and 1.7 g, reacted for 3.5 h; added 270 g of propylene oxide and 1.8 g of benzyltriethylammonium chloride, continued the reaction for 4.5 h, cooled, and discharged; the resulting product was light yellow transparent liquid with an acid value of 1.83 mgKOH / g and a viscosity of It is 7810 mPa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com