Ironing device for garment factory

A garment factory and ironing technology, which is applied in the field of garment equipment, can solve problems such as heavy workload, large output of new clothes, and waste of labor, and achieve the effects of reducing production costs, improving ironing efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, a detailed description will be given below in conjunction with the accompanying drawings and specific embodiments.

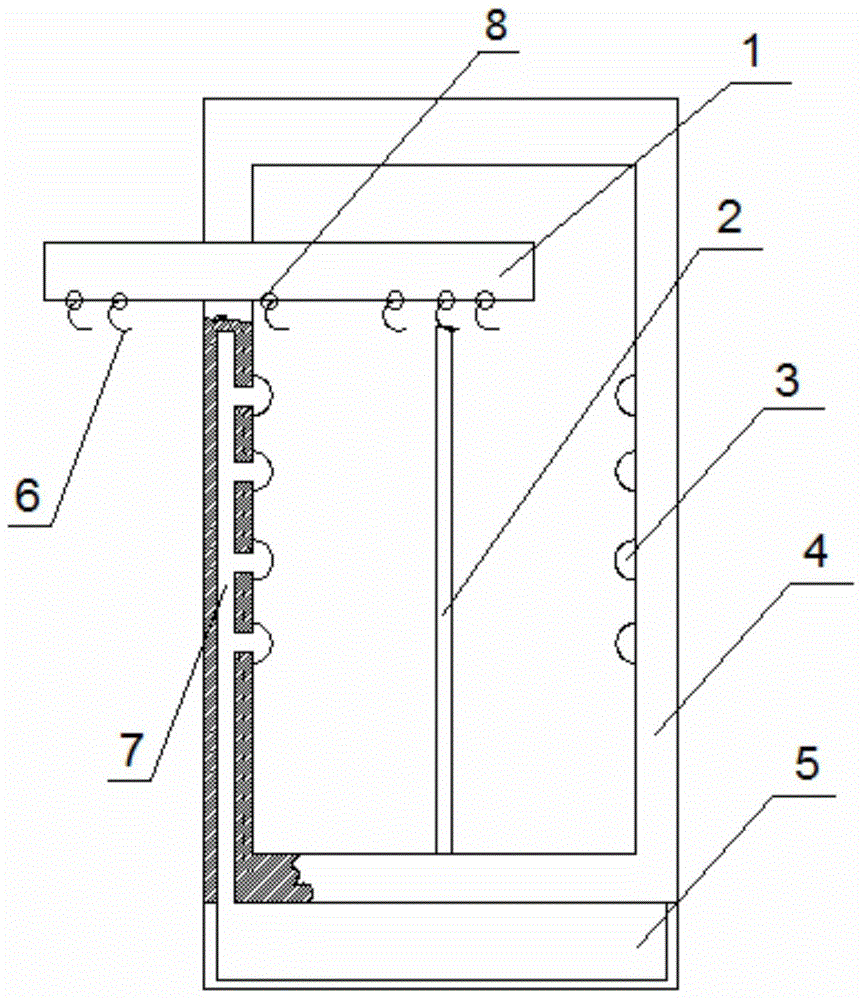

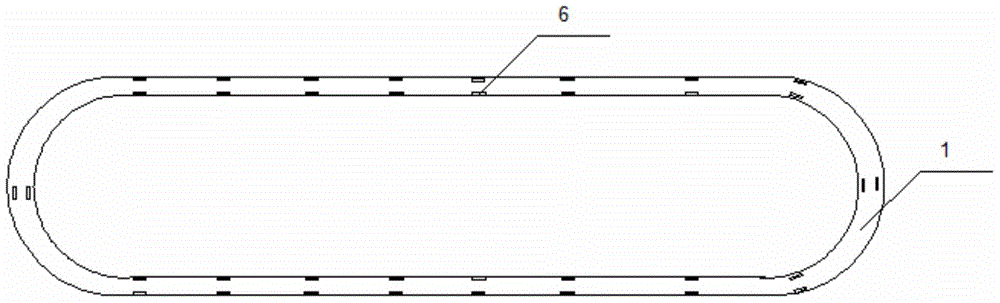

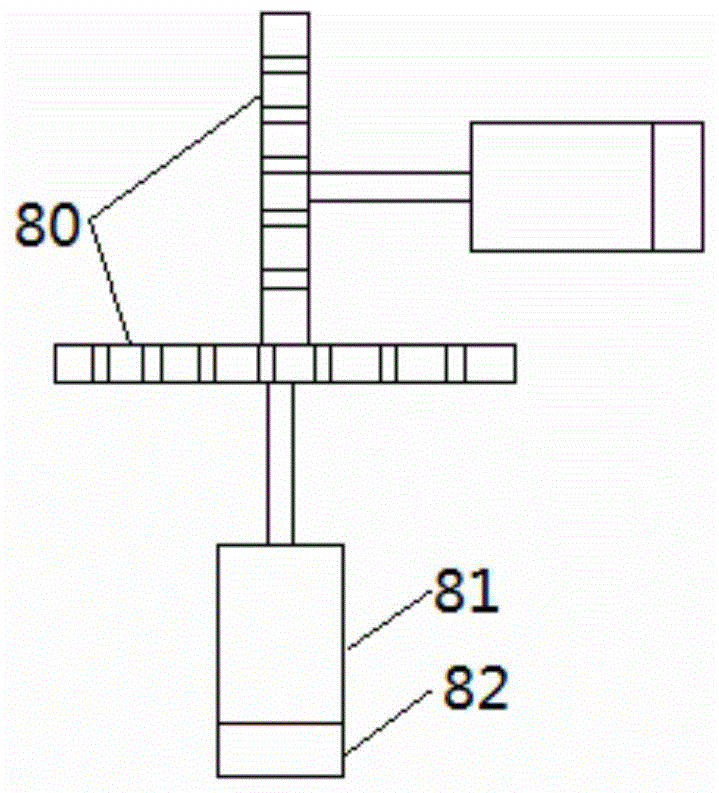

[0019] Such as Figure 1-3 As shown, the present invention provides an ironing device for a garment factory in view of the existing shortcomings. The ironing device includes a steam box 4 and a conveyor belt 1. The conveyor belt 1 has an oval structure, and the conveyor belt 1 partially passes through the steam box 4 Two rows of hooks 6 are evenly distributed on the lower edge of the conveyor belt 1. The hooks 6 are installed at the lower end of the conveyor belt 1 through a rotating shaft 8. Each rotating shaft 8 is provided with two sets of mutually perpendicular gear sets 80, each gear set 80 is connected to a stepping motor 81, and the stepping motor 81 is connected to the controller through a driver 82. A number of steam nozzles 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com