Elastic tensile force adjusting device for traction wheels

A technology of adjusting device and traction wheel, applied in electrical components, circuits, insulating conductors/cables, etc., can solve the problems of unadjustable tension force, complex structure, easy to fall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

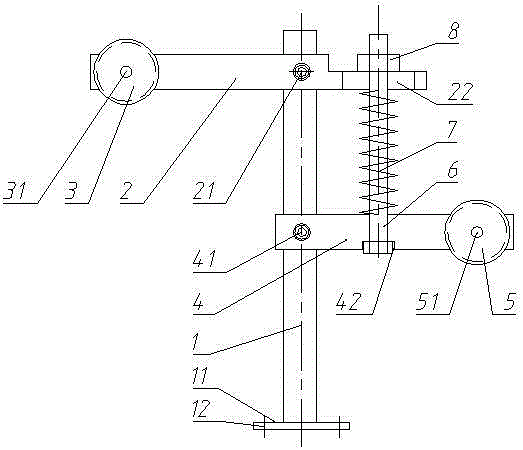

[0010] Below in conjunction with accompanying drawing, the elastic adjustment device of traction pulley tension force of the present invention is further described:

[0011] Depend on figure 1 Visible, the present invention it comprises mounting bracket 1, connecting plate one 2, traction wheel one 3, connecting plate two 4, traction wheel two 5, support screw 6, stage clip 7 and nut 8, described connecting plate one 2 passes through turning Pin one 21 is arranged on the upper end of mounting bracket 1, and described traction wheel one 3 is arranged on one end of connecting plate one 2 by revolving pin two 31, and the other end of described connecting plate one 2 is provided with U-shaped groove 22; One end of the connecting plate 2 4 described above is arranged in the middle of the installation frame 1 through the rotating pin 3 41, the other end of the connecting plate 2 4 is provided with the traction wheel 2 5 through the rotating pin 4 51, and the middle of the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com