Handle structure of dust collector

A vacuum cleaner and handle technology, applied in the field of handle body structure of vacuum cleaners, can solve the problems of long elongation and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] As mentioned in the background technology, the existing structure of the handle body of the vacuum cleaner includes a telescopic rod composed of multi-section rods, and the two-section rods are socketed. The telescopic rod fixing pin of the section bar is inserted into the fixing hole of the next section bar. In this way, the manufacturing cost is high and the process is complicated.

[0025] Next, the specific technical solution of the present invention will be introduced in detail.

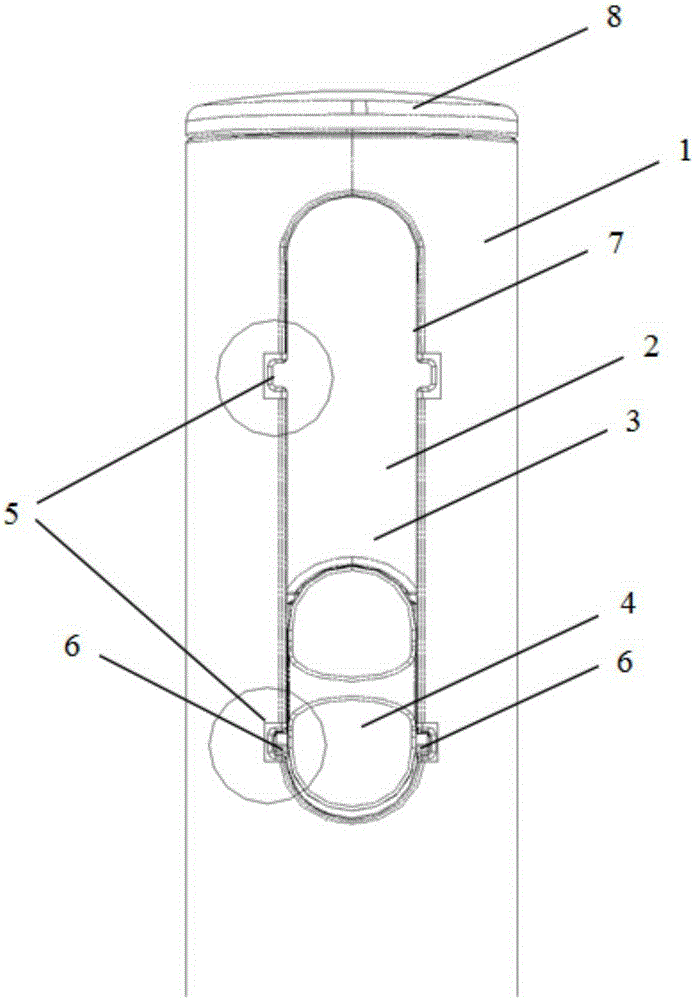

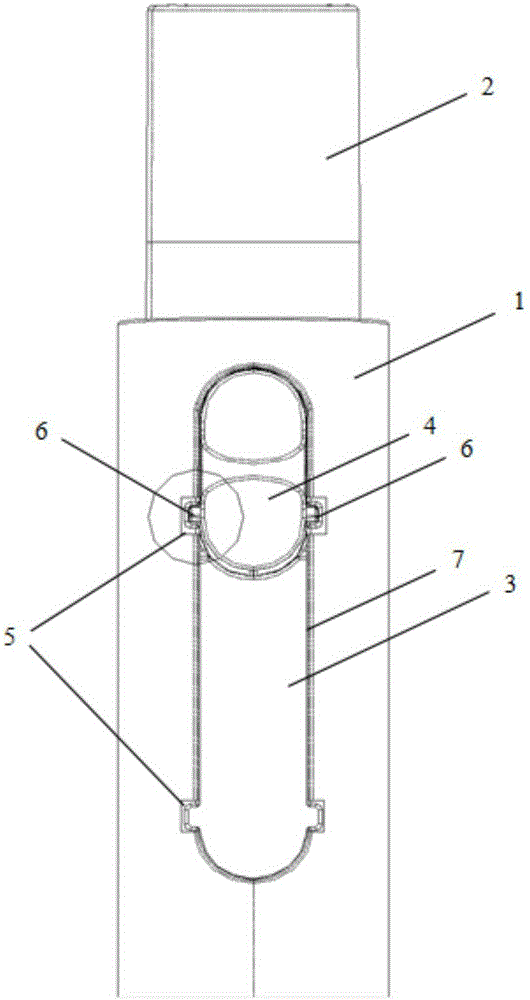

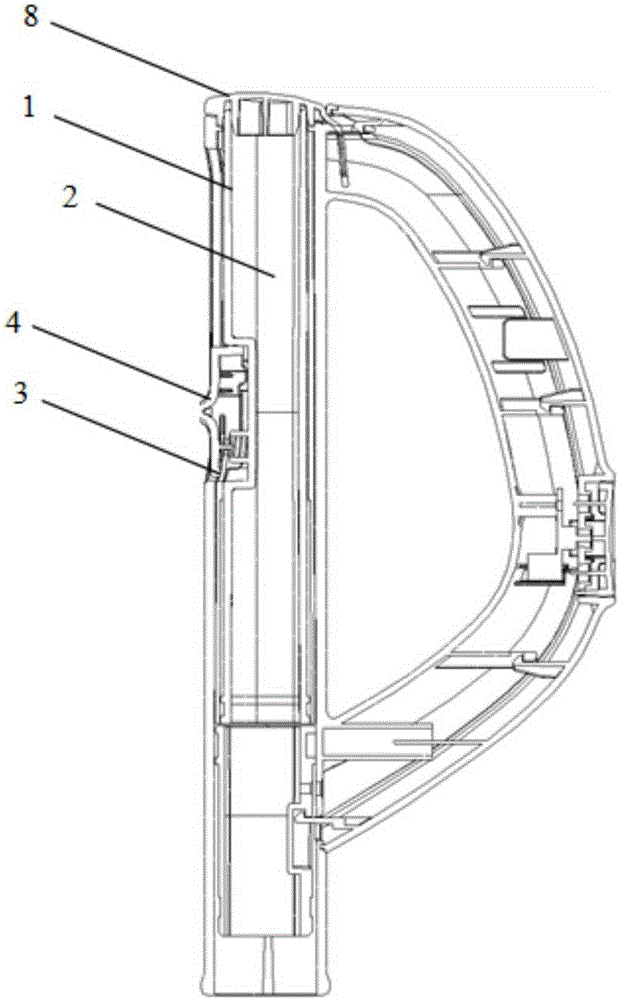

[0026] Please also see Figure 1 ~ Figure 3 , is the handle body structure of the vacuum cleaner in the present invention. There is a telescopic connecting rod 2 at the end of the handle body 1. The connecting rod 2 is sleeved in the handle body 1. The handle body 1 is provided with a chute 3. Can be set to the ellipse of vertical direction, or rectangle, circular shape etc., connecting rod 2 is provided with booster button 4, and booster button 4 is arranged in the chute 3, can slide up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com