Novel equipment capable of automatically outputting, pushing and binding photo frame elastic sheet

A technology of automatic output and binding equipment, which is applied in the direction of hand-held tools and manufacturing tools, which can solve the problems of poor stability of photo frames, dislocation of feet, low binding efficiency, etc., and achieve the effect of stable placement, novel structure and accurate binding position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

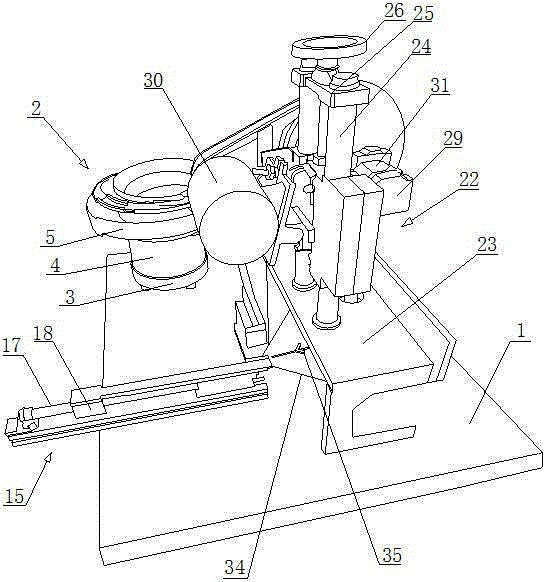

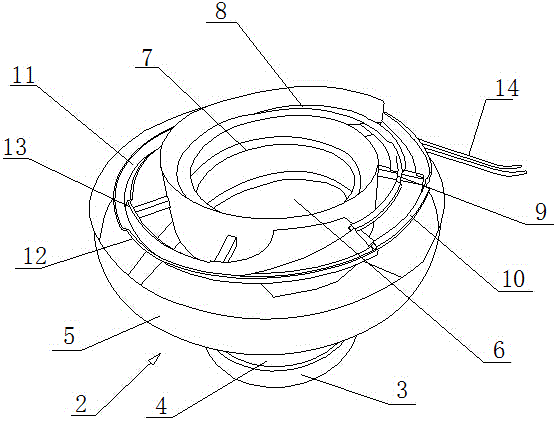

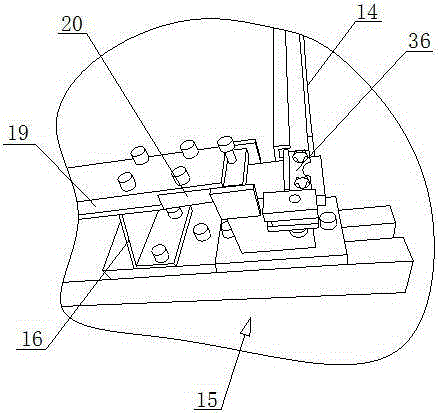

[0020] Such as figure 1 , 2 , 3, 4, and 5, a new type of photo frame shrapnel automatic output push binding equipment, including table body 1, material tray 2, guide rail 14, push frame 15, stapler 22, described material tray 2, guide rail 14, The push frame 15 and the stapler 22 are installed on the table body 1, and the material tray 2 includes a base 3, a shaking tray 4, a receiving tray 5, a chassis 6, a feeding frame 7 and a conveying track 11, a guide rail 14 and a groove 21 For docking, the push frame 15 includes a rodless cylinder 17, a cylinder 18, a push rod 19 and a collet 20, and the stapler 22 includes a column 24, a hand wheel 26, a sliding seat 28, a connecting block 31, a pressing rod 32 and a mounting table 34 . The bottom of the tray 2 is the base 3, the base 3 is provided with a shaking tray 4, the shaking tray 4 is provided with an upwardly open receiving tray 5, the inner bottom of the tray 2 is a chassis 6, and the inner wall is welded spirally upwards ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com