Method of making cover fixing type pipe for safety belt

A manufacturing method and safety belt technology, applied in the direction of manufacturing tools, positioning devices, perforating tools, etc., can solve problems such as operating speed disadvantages, and achieve the effects of simple manufacturing process, easy flattening, and accurate joint position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention relates to a method of manufacturing a tube for a seat belt, that is, a method of manufacturing a seat belt tube of a cover fixing method, in which an open groove is formed on one side of the tube bent according to the shape of the tube to be manufactured by using an open groove punching machine , to flatten the outer part forming the open groove, so that the combination position with the cover is accurate, and at the same time, the manufacturing process is simple.

[0039] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

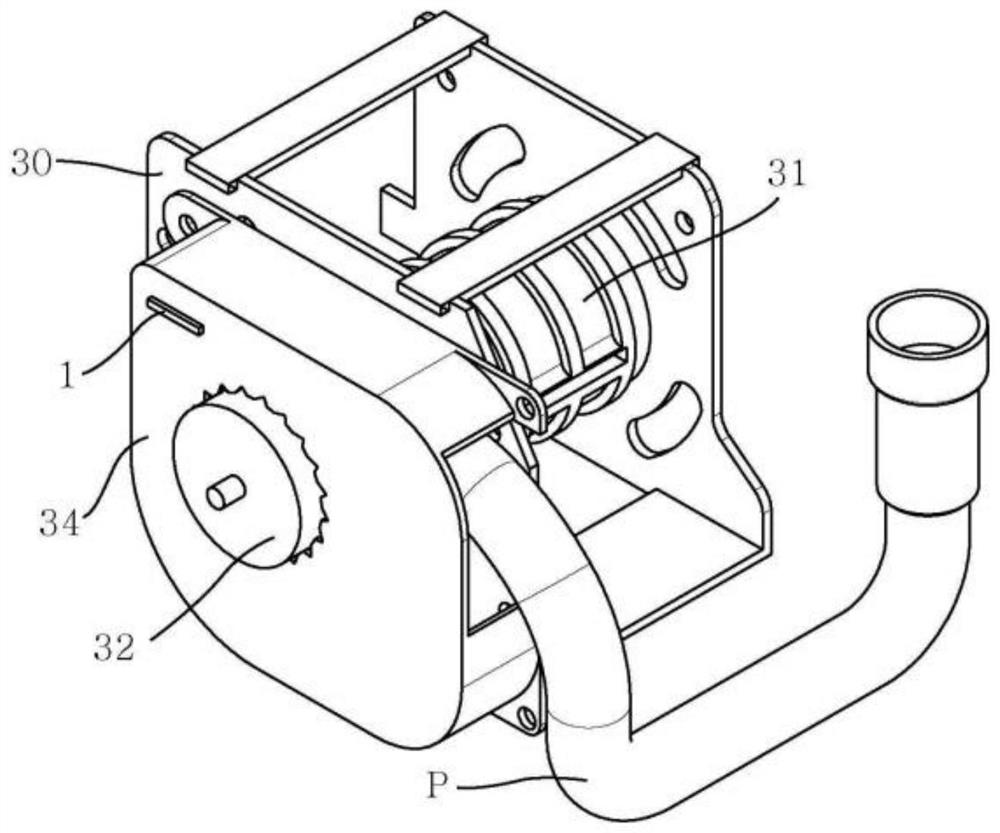

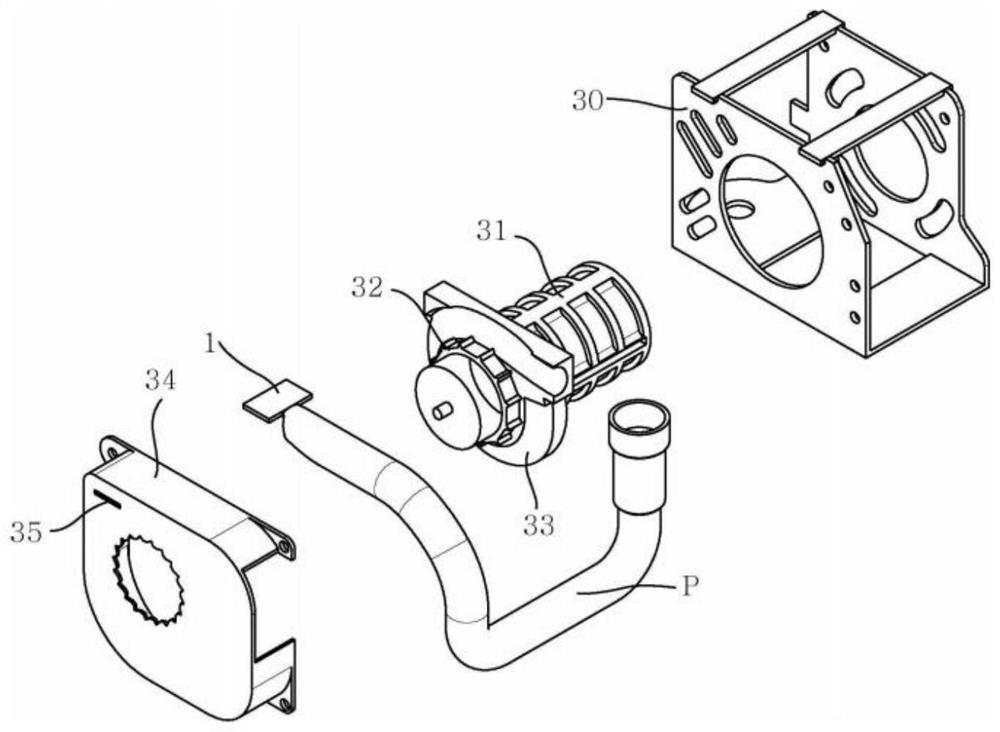

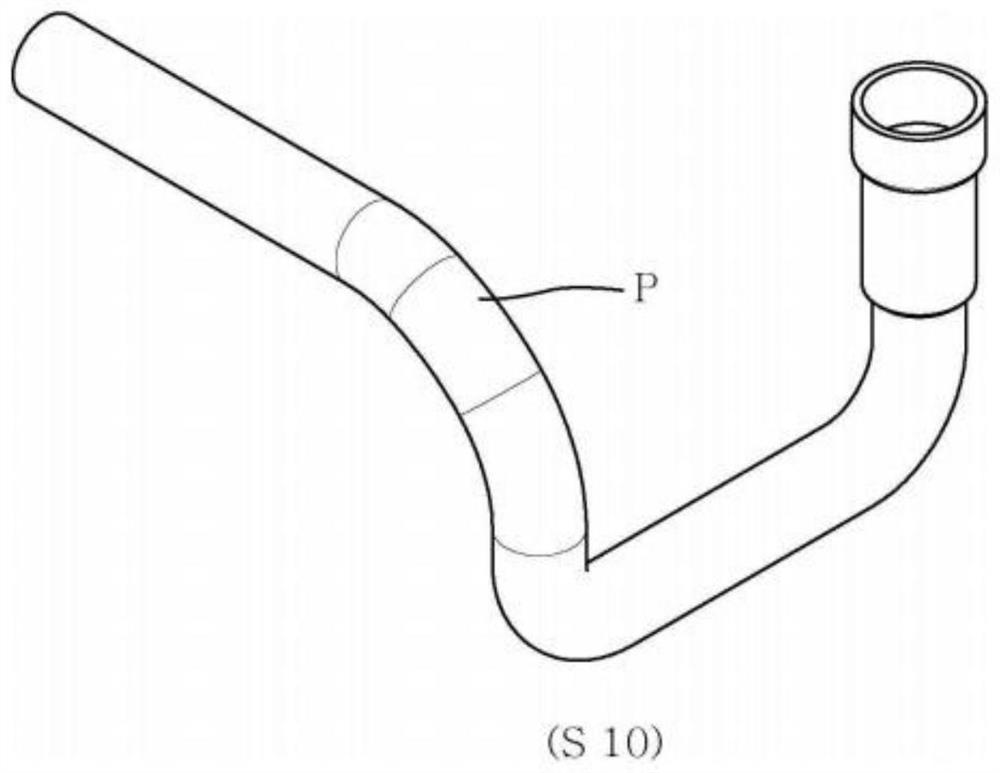

[0040] figure 1 It is a diagram of the installation state of the telescoping device of the pipe of the present invention, figure 2 yes figure 1 The disassembled structure diagram, the pipe to be manufactured in the present invention is a pipe used for a safety belt retractable device having a form as shown in the figure, the inside of the pipe P has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com