Injection molding method of metal parts, injection molding structural parts with metal parts and mobile terminal

A technology for metal parts and structural parts, applied in the field of injection molding structural parts, mobile terminals, and metal parts, can solve problems such as inability to achieve, and achieve the effect of enhancing the drawing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

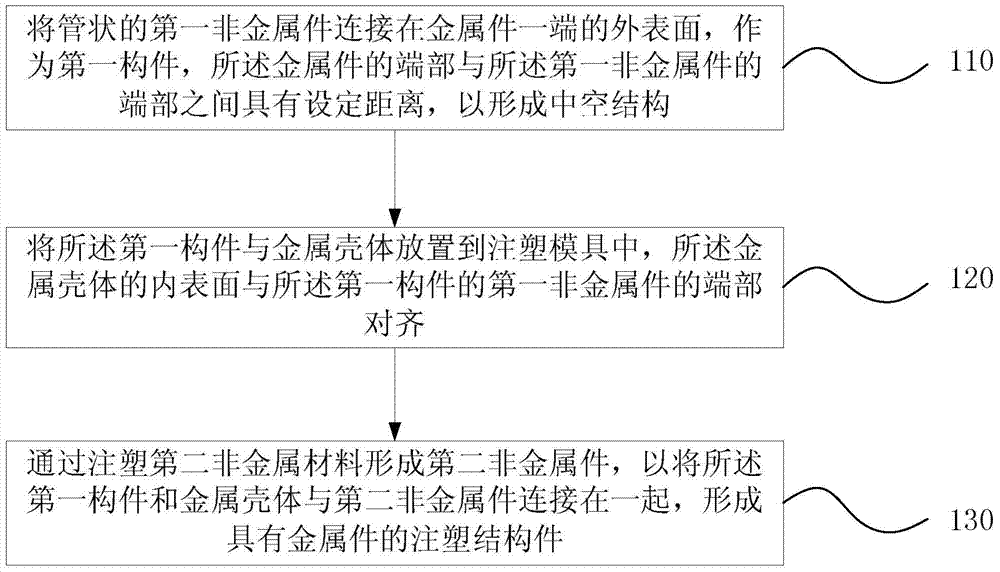

[0021] figure 1 It is a flow chart of an injection molding method for a metal part provided by Embodiment 1 of the present invention. This embodiment is applicable to the situation where there needs to be a certain distance between the metal part and the metal shell in the mobile terminal and the metal shell cannot open holes. The components prepared by the method are as Figure 2A-Figure 2C As shown, it specifically includes the following steps:

[0022] Step 110, connecting a tubular first non-metallic piece to the outer surface of one end of the metal piece, as a first component, there is a set distance between the end of the metal piece and the end of the first non-metallic piece, to form a hollow structure;

[0023] Preferably, the metal piece is a metal nut. The metal nut can be used to fix some jacks of the mobile terminal, such as an earphone jack or a USB jack.

[0024] Further, in order to have a good bonding force between the metal nut and the first non-metal pa...

Embodiment 2

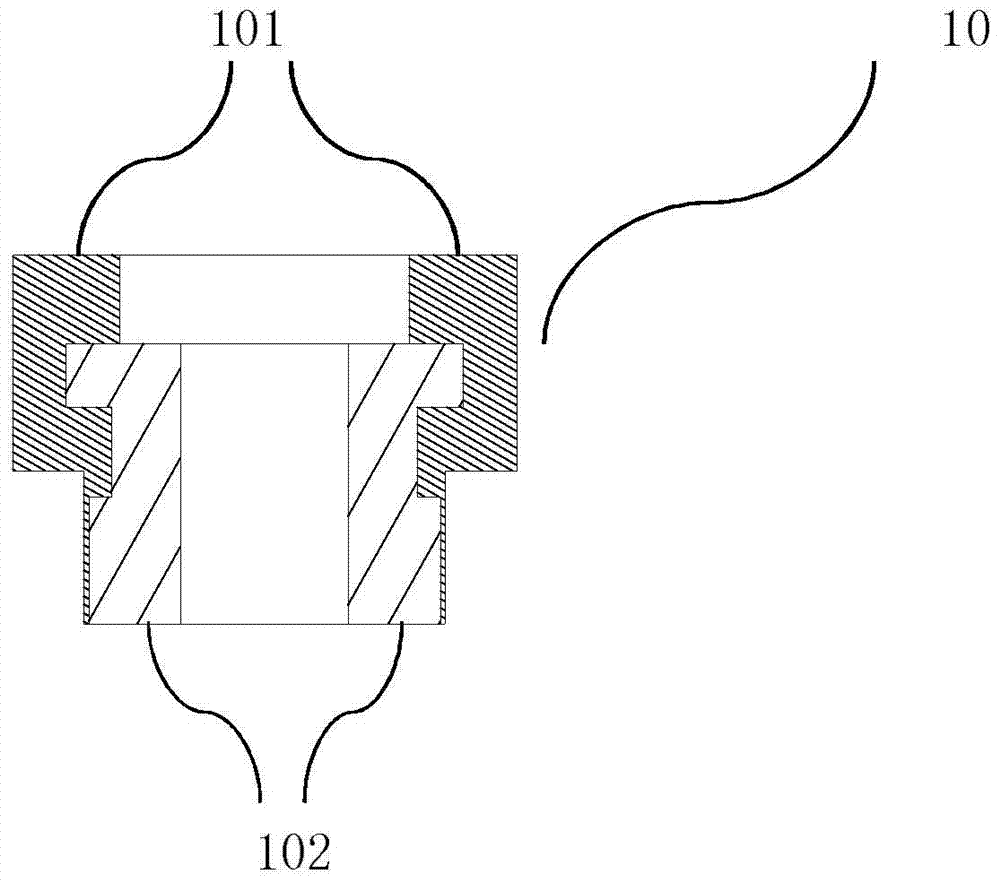

[0039] The second embodiment provides an injection molded structural part with metal parts, which is made by the method of the first embodiment, referring to the first embodiment Figure 2A The structural schematic diagram of the first member shown, and referring to the first embodiment Figure 2C Schematic diagram of the structure of the injection molded structural part with metal parts shown.

[0040] Such as Figure 2A As shown, the first member 10 includes a tubular first non-metallic part 101 and a metal part 102; the first non-metallic part 101 is connected to the outer surface of one end of the metal part 102, and the first non-metallic part 101 There is a set distance between the end of the metal piece 102 and the end of the metal piece 102 to form a hollow structure.

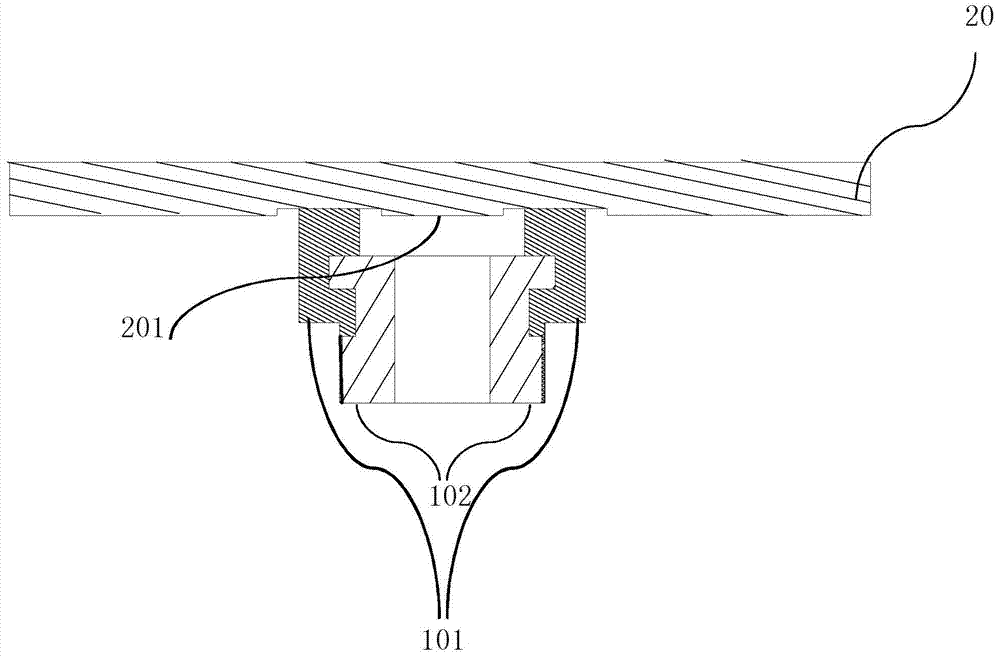

[0041] Such as Figure 2C As shown, the injection molded structural part 40 with metal parts includes: a first member 10, a metal shell 20 and a second non-metallic part 30;

[0042] Wherein, the in...

Embodiment 3

[0049] image 3 It is a schematic structural diagram of a mobile terminal provided by Embodiment 3 of the present invention. The mobile terminal 50 includes the injection molding structural member 40 with metal parts and the socket 60 of the terminal housing described in the above embodiments. The injection molding structural part 40 is used to fix the socket 60 of the terminal housing, and the injection molding structural part 40 with metal parts in the mobile terminal 50 is made by the method described in the first embodiment.

[0050] Preferably, the jack 60 of the terminal housing includes a USB jack or an earphone jack.

[0051] Among them, the jacks 60 of these terminal housings need to be fixed in the mobile terminal 50, and many fixing methods can be selected, such as injection molding or glue fixed connection, preferably through nuts and screws. The injection molding structural parts of the parts are formed by the injection molding method described in the above embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com