Hydrodynamic bearing device

A technology of fluid dynamic pressure bearings and bearing devices, which is applied in the direction of sliding contact bearings, bearings, and rotating bearings. It can solve the problems of time-consuming and labor-intensive processing of gate marks, and reduce processing costs. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

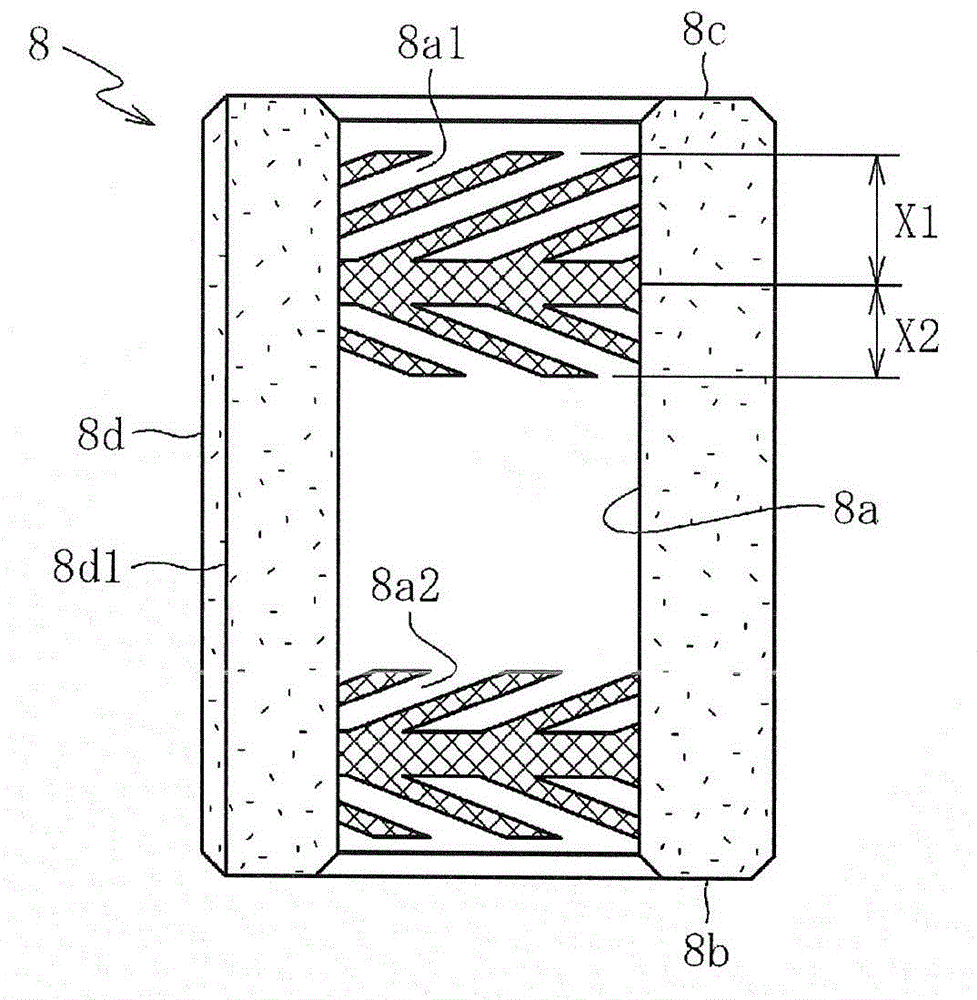

[0103] In order to confirm the effect of the present invention, as Figure 9 As shown, a sleeve test piece 130 having the same structure as the bearing sleeve 8 of the above-mentioned embodiment was press-fitted into the inner periphery of a seal test piece 140 having the same structure as the above-mentioned seal member 9, and it was checked whether the seal test piece 140 was damaged. test. For the sealing test piece 140, an embodiment in which a welding line is formed in the middle of the axial groove in the circumferential direction (refer to Figure 5 ) and a comparative example (not shown) in which the welding wire is formed at the position in the circumferential direction of the deepest part of the axial groove. Furthermore, as the sealing test piece 140 of the example and the comparative example, various kinds of test pieces having different inner diameter dimensions of the cylindrical portion 141 , that is, various kinds of test pieces having different pressing margi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com