Rotor punching plate, motor rotor and motor

A technology for rotor punching and motor rotors, which is applied to the rotating parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., and can solve the problems of insignificant skin effect, large slot leakage reactance, and low air gap magnetic density. , to achieve the effect of increasing skin effect, improving performance and uniform magnetic density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The core of the present invention is to provide a rotor punch to increase the skin effect of the motor, while ensuring uniform magnetic density at the tooth portion and good operating performance;

[0019] Another core of the present invention is to provide a motor rotor and a motor.

[0020] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solutions of the invention described in the claims.

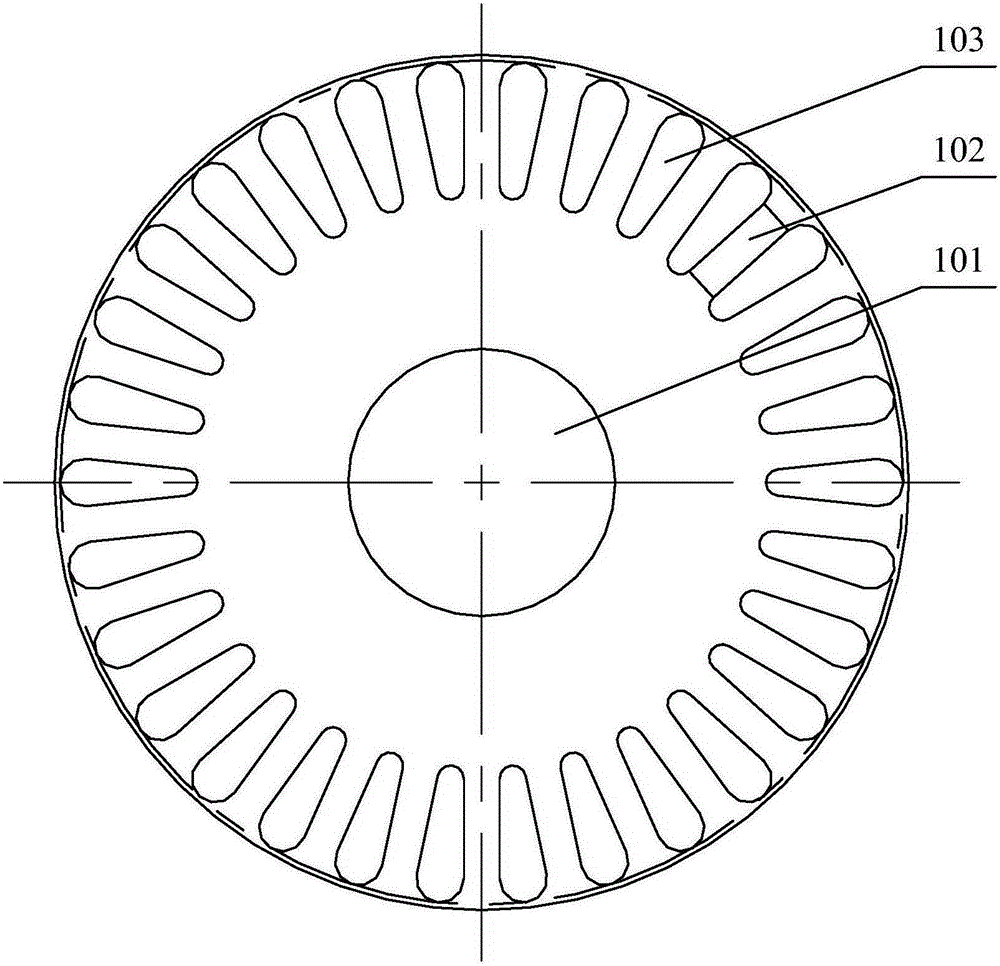

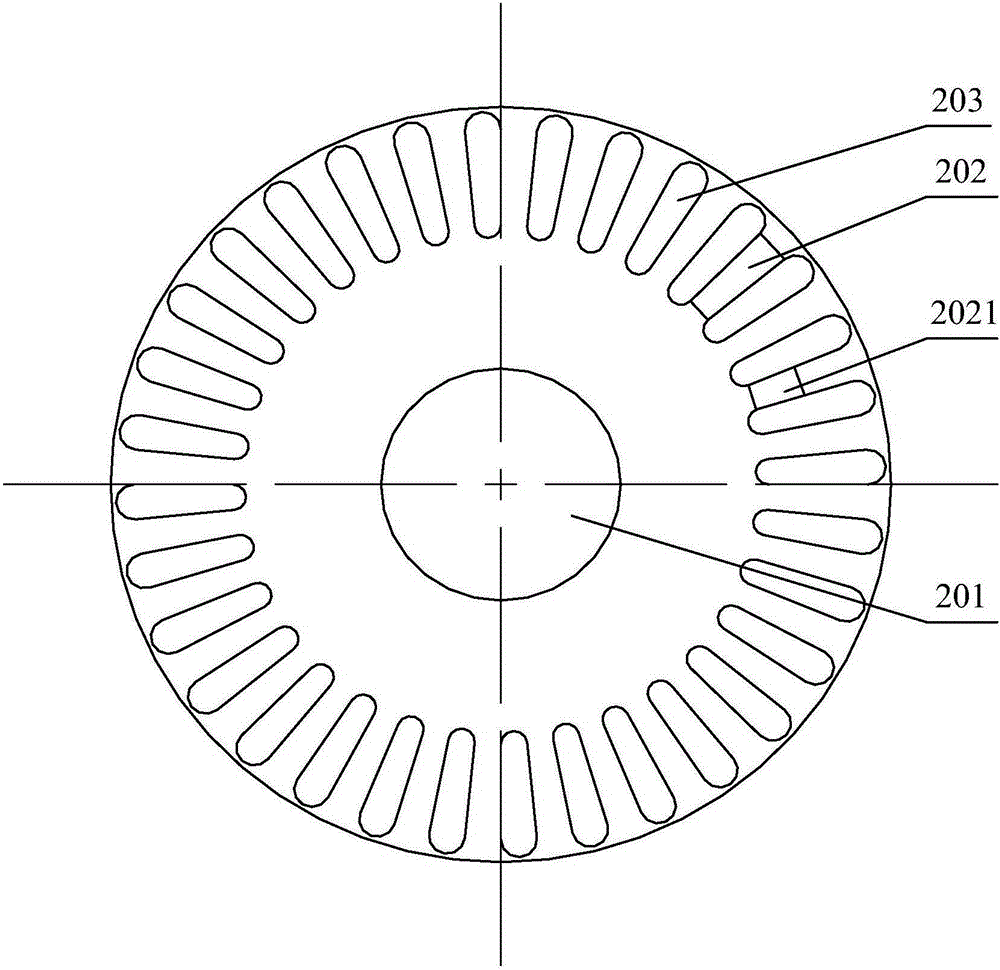

[0021] see figure 2 , figure 2 It is a schematic structural diagram of the rotor punch provided by the embodiment of the present invention.

[0022] The rotor stamping provided by the embodiment of the present invention includes a rotor stamping body, the periphery of the rotor stamping body is provided with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com