A kind of automatic feeding machine for numerical control lathe

A technology of automatic feeding and CNC lathe, which is applied in the direction of automatic input/exit of workpieces, metal processing machinery parts, metal processing equipment, etc., which can solve the problems of difficulty in ensuring the stability of workpiece product quality and low mode efficiency, and reduce the number of labor and operating time, improve production efficiency, and ensure the effect of stability

Active Publication Date: 2019-01-22

盐城华睿通机械有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, workers usually manually operate the loading and unloading process of CNC lathes. Each lathe must be equipped with a worker. However, this manual operation mode is inefficient and prone to large errors, making it difficult to ensure the stability of the product quality of the workpiece. With the rise of domestic labor costs, downstream enterprises have stricter quality requirements. Therefore, how to liberate laborers from simple repetitive mechanical labor, improve the scale of product production, and ensure consistent product quality These issues have become the focus of research by those skilled in the art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

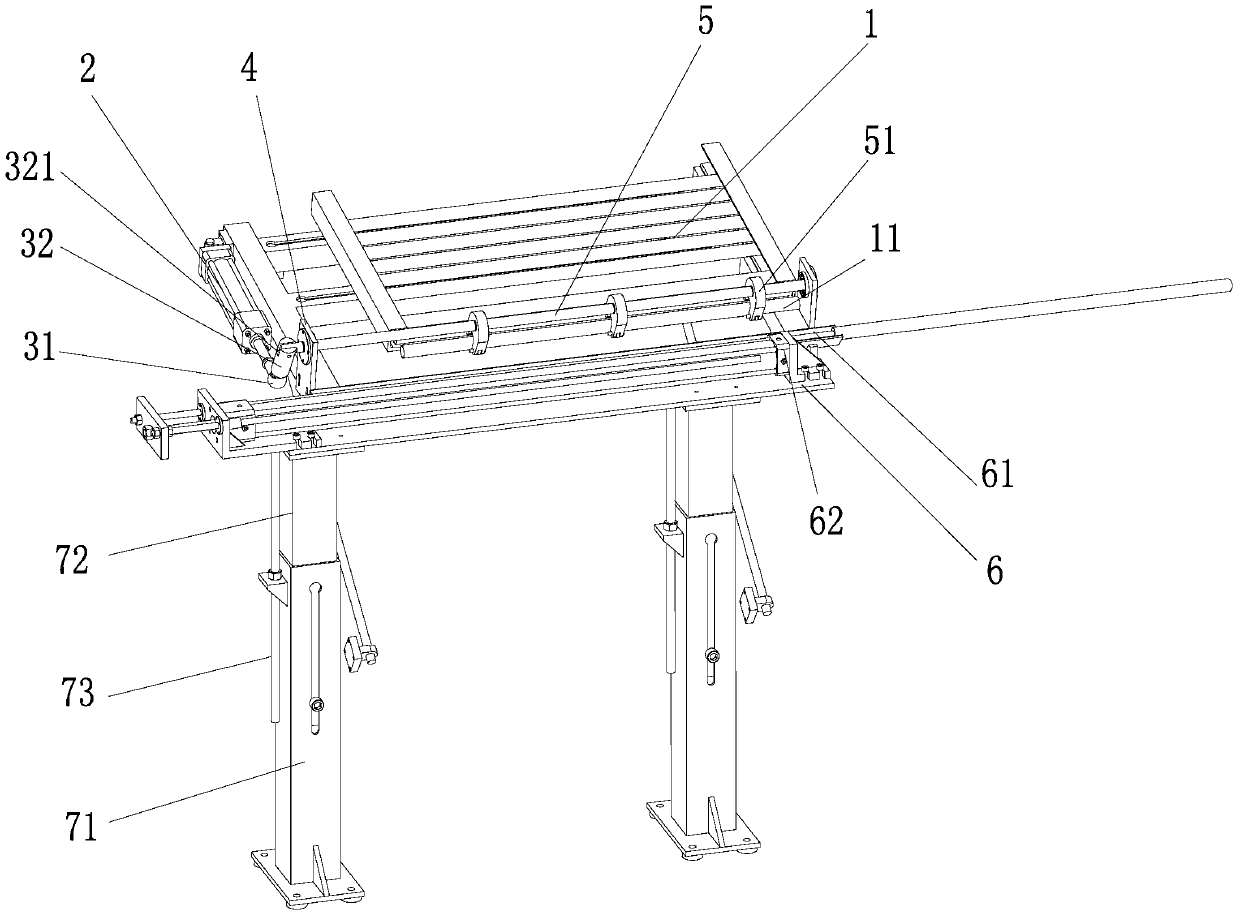

The invention discloses an automatic feeder for a numerical control lathe. The automatic feeder comprises a rack and a feeding tray which is arranged on the rack and used for containing workpieces. A material stirring driver is arranged at the lateral end of the feeding tray. A stirring wheel fixed rod is in rotary connection with the feeding tray through supports. The material stirring driver is connected with the stirring wheel fixed rod through a shifting fork. A supporting plate with supporting feet and a baffle groove is arranged in front of the material stirring driver. A plurality of material stirring devices used for stirring the workpieces to the baffle groove are arranged in the middle of the stirring wheel fixed rod. The supporting plate is further provided with a material pushing driver used for pushing the workpieces in the baffle groove into a spindle hole of the lathe. According to the automatic feeder, workers are liberated from simple repeated labor, the labor intensity of the workers and the enterprise production cost are reduced, the large-scale production level of products is improved, and meanwhile the stability of product quality is guaranteed.

Description

technical field The invention relates to the technical field of application of numerical control lathes, in particular to an automatic feeder for numerical control lathes. Background technique At present, workers usually manually operate the loading and unloading process of CNC lathes. Each lathe must be equipped with a worker. However, this manual operation mode is inefficient and prone to large errors, making it difficult to ensure the stability of the product quality of the workpiece. With the rise of domestic labor costs, downstream enterprises have stricter quality requirements. Therefore, how to liberate laborers from simple repetitive mechanical labor, improve the scale of product production, and ensure consistent product quality These issues have become the focus of research by those skilled in the art. Contents of the invention In order to overcome the deficiencies of the prior art, the present invention provides a hydraulic automatic feeder for CNC lathes that ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23B15/00

CPCB23Q7/06B23Q2707/003

Inventor 李双喜

Owner 盐城华睿通机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com