Machining and positioning method for elbow parts

A technology of parts processing and positioning method, which is applied in the direction of metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of increased part scrap rate, easy to produce defective products, low positioning accuracy, etc., and achieve high positioning accuracy and efficiency , The positioning method is simple, and the effect of improving the qualified rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

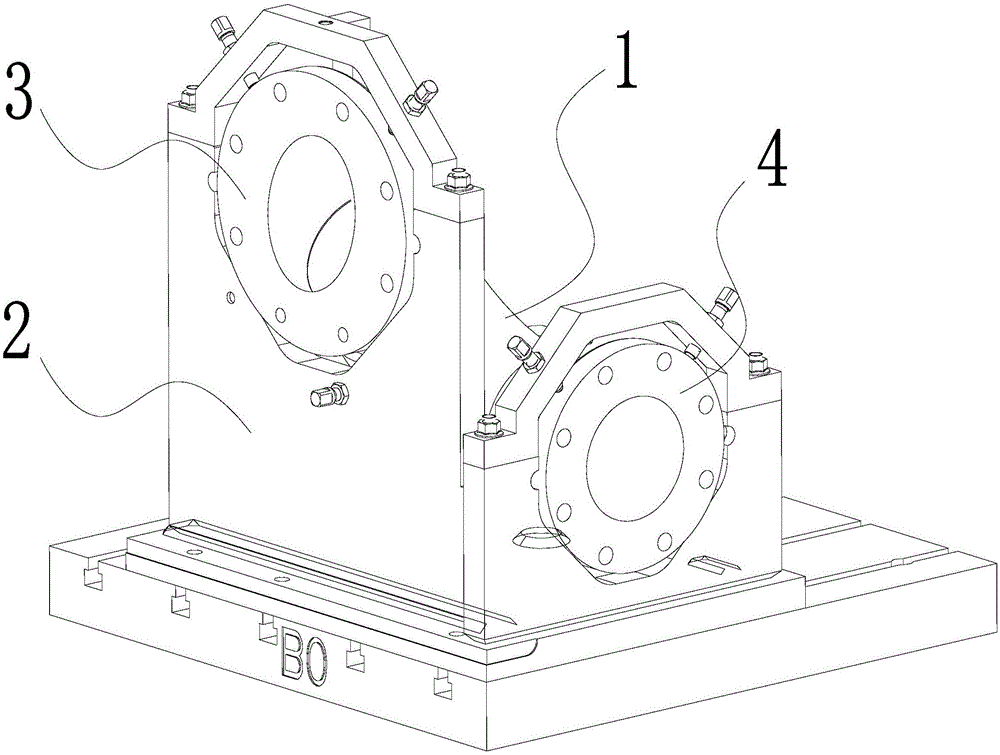

[0019] Such as figure 1 As shown, the method for processing and positioning elbow parts of the present invention includes the following sequential steps:

[0020] 1) Take the elbow 1 and clamp it on the elbow positioning tool 2, and make the flange surface A3 and flange surface B4 of the two ports of the elbow 1 face outward horizontally, and keep the flange surface A3 and flange surface B4 in line with the horizontal plane vertical;

[0021] 2) With the flange surface A3 as the reference, use the probe to detect and correct the center reference aa of the flange surface A3;

[0022] 3) Use the corrected flange surface A3 center datum to convert the theoretical flange surface B4 center datum ba;

[0023] 4) Use the converted theoretical flange surface B4 center reference ba as a reference, use the probe to detect the flange surface B4 center reference bb, and calculate the difference between the detected flange surface B4 center reference bb and the theoretical flange surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com