Instrument panel blind area measuring apparatus matched with an H-point apparatus and positioning method thereof

A measuring device and instrument panel technology, which is applied in the direction of measuring device, vehicle test, machine/structural component test, etc., can solve problems such as inability to intuitively obtain the blind area of the instrument panel, and there will be gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Embodiment 1 For Class A vehicles

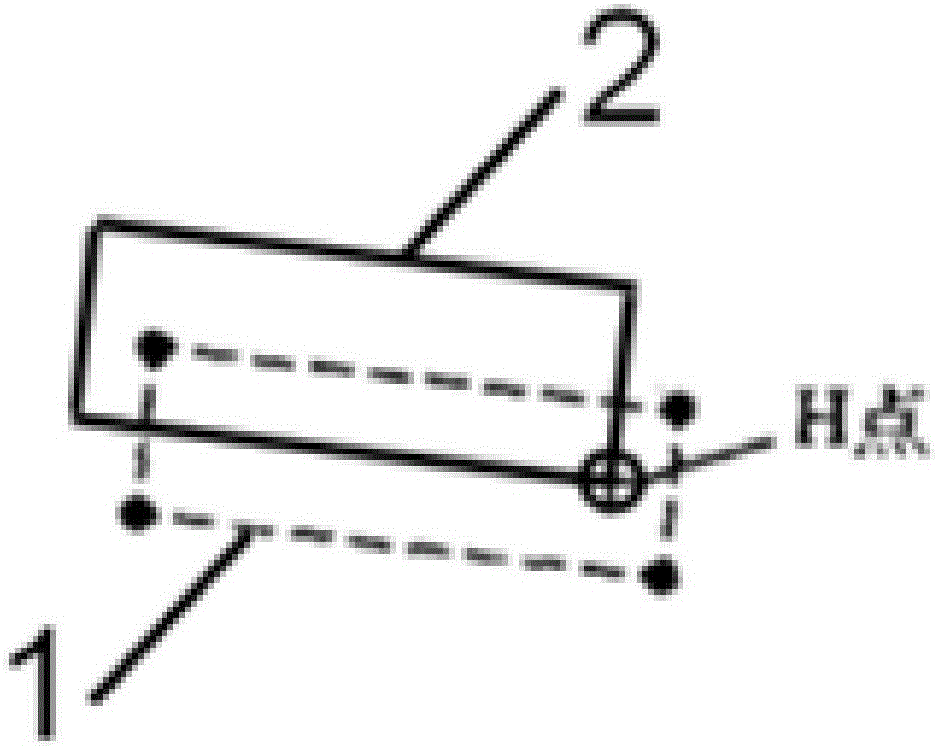

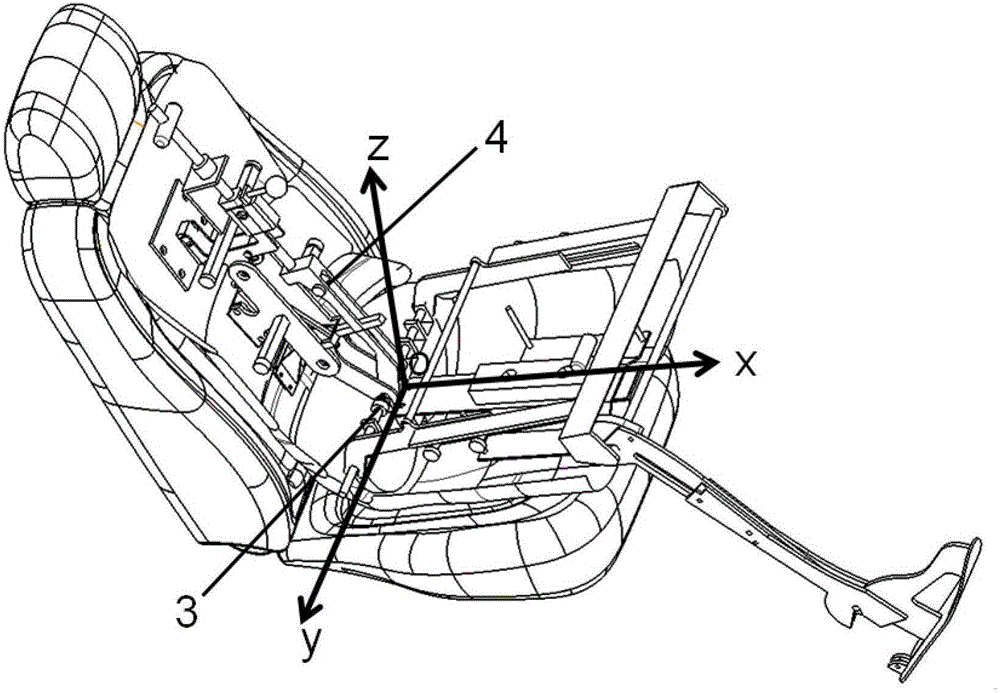

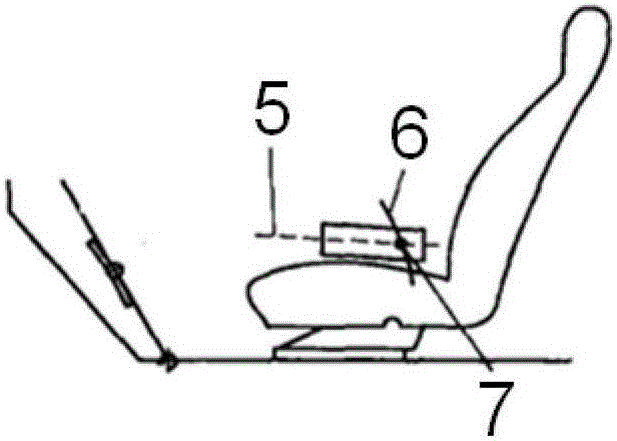

[0087] (1) Seat position positioning

[0088] Find a mark point on the seat at random, and record its coordinates in the X and Z directions relative to the reference points BOF and AHP of the accelerator pedal when the seat is adjusted to the lowest position, the highest position, the highest position, and the lowest position. The connecting line at the four positions is the trajectory line 1 of the seat stroke, such as figure 1 shown. Then look for seat H point travel 2, which is the same shape and size as the seat travel. Install the H-point device on the seat according to the installation sequence of the H-point device, such as figure 2 shown. Find the actual H-point position of the seat when the seat is adjusted to the lowest and final position, and record the coordinates of the H-point position at this time. This position is also the lowest final position of the H point travel trajectory line. According to the coordinates ...

Embodiment 2

[0103] Embodiment 2 For Class B vehicles

[0104] (1) Seat position positioning

[0105] Similar to the method of class A vehicles, randomly search for a mark point on the seat, and record its X and Z directions relative to the reference point AHP of the accelerator pedal when the seat is adjusted to the lowest position, the highest position, the highest position, and the lowest position. The coordinates of the marked points at the four positions are the trajectory line 1 of the seat stroke, such as figure 1 shown. Then look for seat H point travel 2, which is the same shape and size as the seat travel. Install the H-point device on the seat according to the installation sequence of the H-point device, such as figure 2 shown. Find the actual H-point position of the seat when the seat is adjusted to the lowest and final position, and record the coordinates of the H-point position at this time. This position is also the lowest final position of the H point travel trajector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com