Exhaust aftertreatment device for internal combustion engine and vehicle with same

A technology for exhaust post-treatment and internal combustion engines, which is applied in the direction of internal combustion piston engines, exhaust devices, exhaust treatment, etc., and can solve the problems of not providing adequate mixing of reactants and exhaust gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

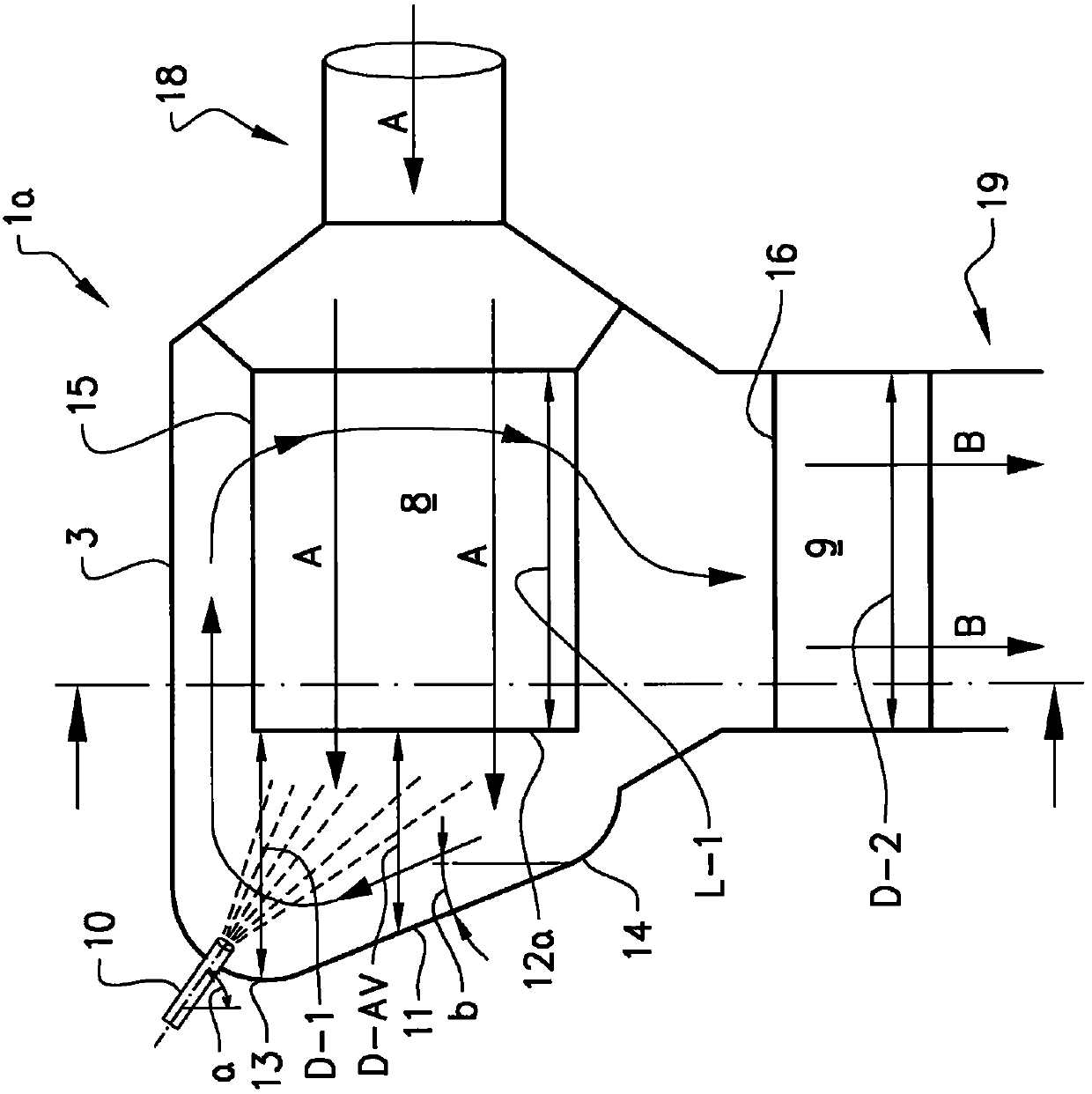

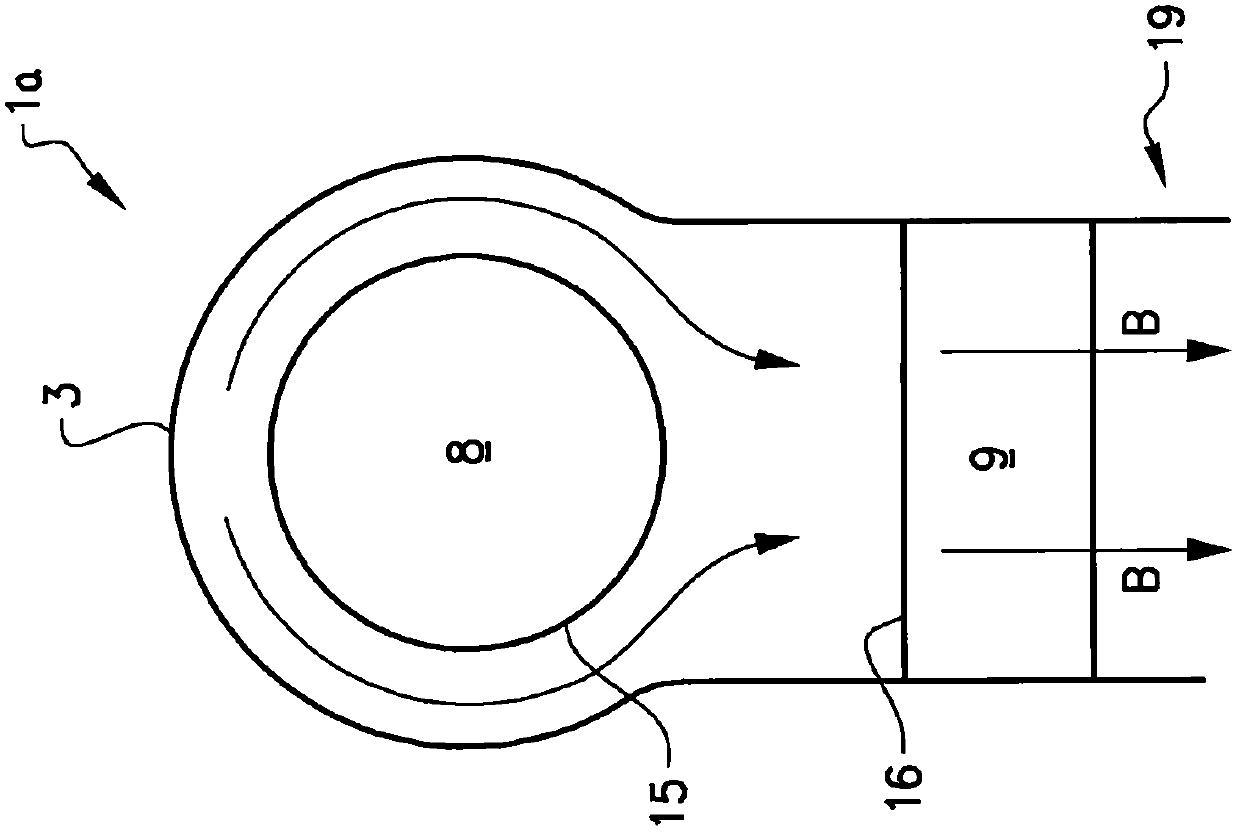

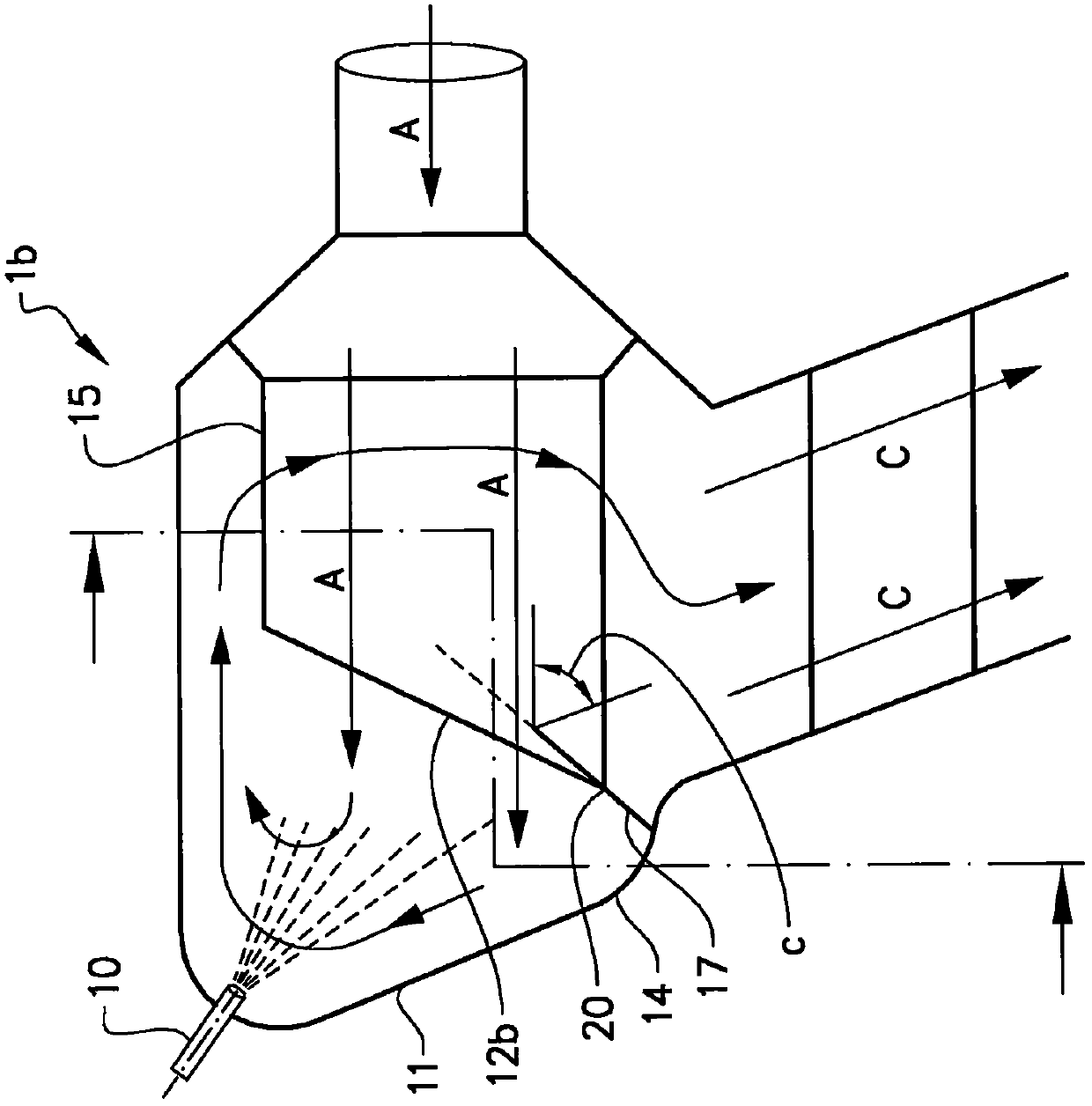

[0037] The accompanying drawing la discloses a compact exhaust aftertreatment device 1a according to a first embodiment of the invention, which device is arranged to receive exhaust gas from an internal combustion engine at an inlet portion 18 of said exhaust aftertreatment device. The exemplary exhaust aftertreatment device includes a first catalytic substrate 8 and a second catalytic substrate 9 of the SCR type. The first catalytic substrate 8 can be DOC type, LNT type or their combination.

[0038] Due to the limited space available for mounting an exhaust aftertreatment device, it is generally desirable for an exhaust aftertreatment device to be as compact as possible, even if the exhaust aftertreatment device includes two catalytic substrates. However, a compact, two-substrate exhaust aftertreatment device often means that the distance between the substrates is limited, which can pose problems, for example from the point of view of exhaust gas mixing. The compact arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com