Manual opening-closing type fast concentration melting furnace

A centralized melting furnace, opening and closing technology, applied in the direction of furnace, furnace type, furnace components, etc., can solve the problems of incomplete discharge, easy blockage, slow discharge, etc., and achieve the effect of saving the cost of feeding and convenient feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

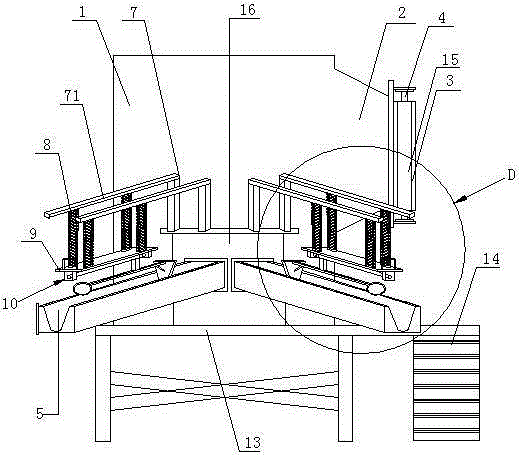

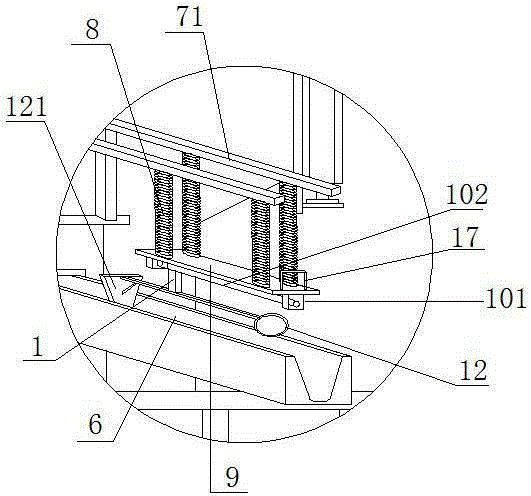

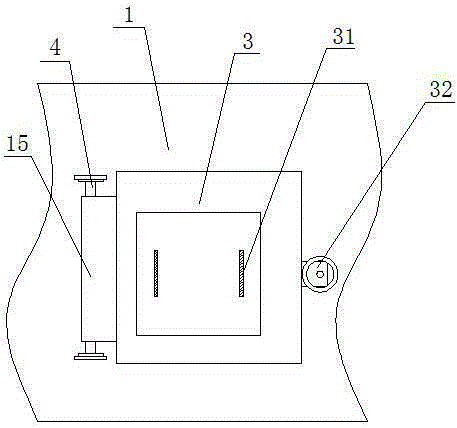

[0022] Refer to attached Figure 1-4 The shown manual opening and closing fast centralized melting furnace includes a furnace body 1, the furnace body 1 is fixed on a bracket 13, and a ladder 14 is arranged on one side of the bracket 13, and one side of the furnace body 1 is arranged At the feed end, the front end is provided with a discharge end 16, and two discharge troughs 15 and 26 in a "V" structure are arranged at the discharge end 16, and the two discharge troughs are simultaneously discharged to raise the output. The material efficiency, and the "V" structure can make the two discharge troughs separate, the two do not affect each other, and increase the space for taking materials at the end, the discharge ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com