A smooth plug gauge for measuring incomplete holes and its design method

A design method and technology of plug gauges, applied in measuring gauges, plug gauges, etc., can solve the problems that measuring tools cannot be directly measured, the problems of parts accuracy detection, and detection difficulties, etc., and achieve simple structure, simple design method, and easy manufacture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

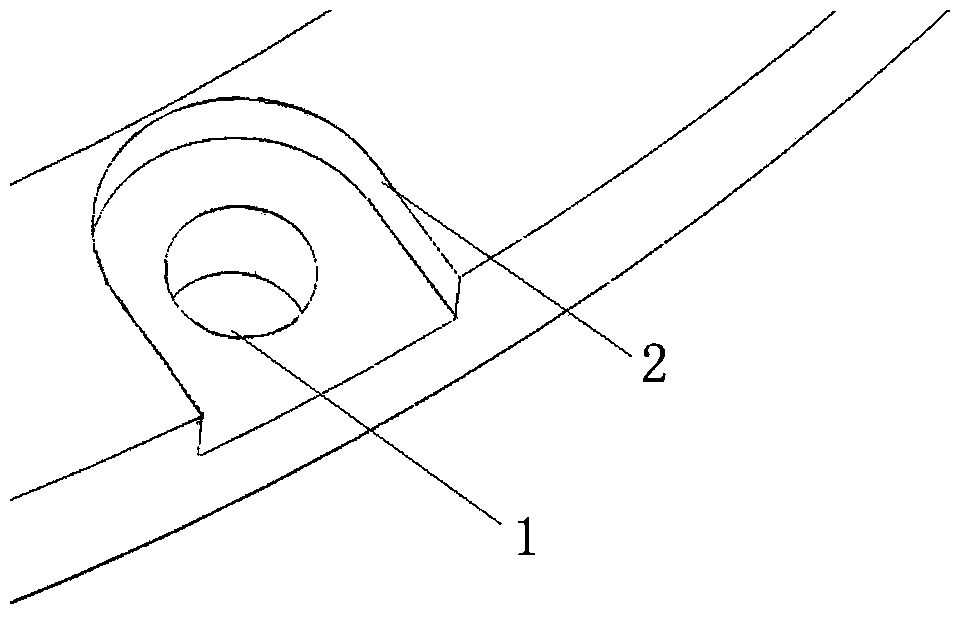

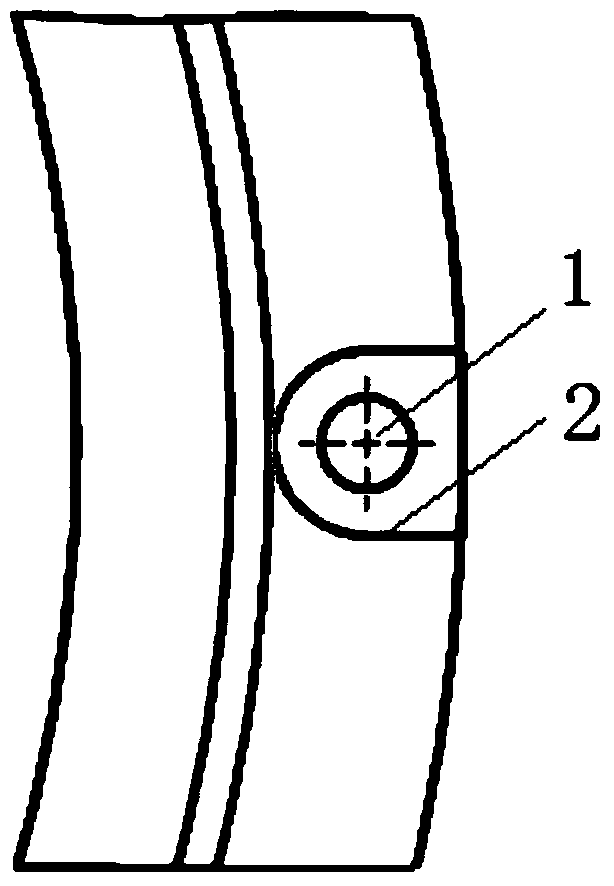

Method used

Image

Examples

Embodiment 1

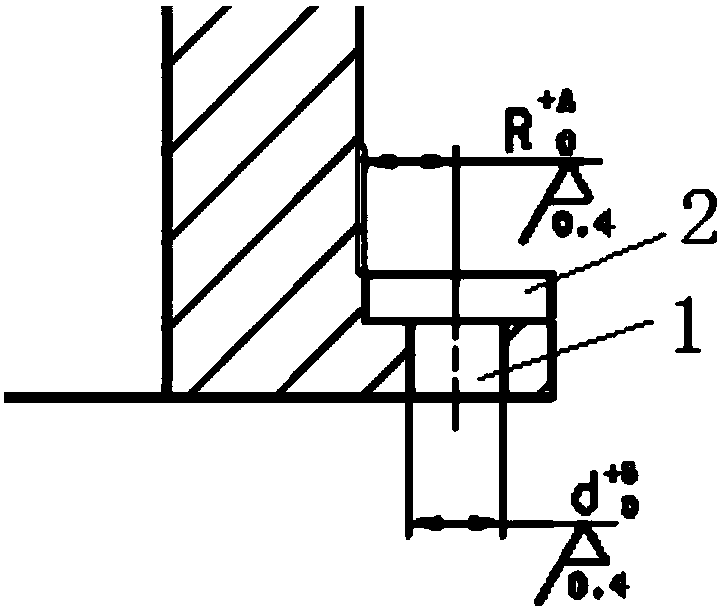

[0056] Embodiment 1: (dimension unit: mm)

[0057] The part hole size is: deep 8 and measuring in R hole length 5.

[0058] The plug gauge size is designed as:

[0059] a Positioning part: The length L1 is taken as 5.

[0060] bMeasurement part: through end Rm=6 / 2+10-6 / 2=10; tolerance of Rm

[0061] End stop Rn=(6+0.015) / 2+(10+0.08)-6 / 2=10.0875; tolerance of Rn

[0062] The length L2 is 6.

[0063] c Plug gauge handle size: ¢D=(Rm-1)=10-1=9.

Embodiment 2

[0064] Embodiment 2: (dimension unit: mm)

[0065] The part hole size is: deep 4 and measuring at R hole length 10.

[0066] The plug gauge size is designed as:

[0067] a Positioning part: The length L1 is taken as 4.

[0068] bMeasuring part: Rm=10.02 / 2+(8+0.04)-10.02 / 2=8.04 at the through end; tolerance of Rm

[0069] End stop Rn=(10+0.03) / 2+(8+0.12)-10.02 / 2=8.125; tolerance of Rn The length L2 is taken as 10.

[0070] c Plug gauge handle size: ¢D=Rm-1=8-1=7.

Embodiment 3

[0071] Embodiment 3: (dimension unit: mm)

[0072] The part hole size is: 15 deep and measure at R hole length 3.

[0073] The plug gauge size is designed as:

[0074] a Positioning part: Since the length of the part is greater than 5, L1 takes 7.

[0075] bMeasuring part: Rm=12 / 2+(15+0.1)-12 / 2=15.1 at the through end; tolerance of Rm

[0076] End stop Rn=(12+0.1) / 2+(15+0.3)-12 / 2=15.35; tolerance of Rn

[0077] Because the part hole length is less than 5, so L2=3+1=4.

[0078] The handle size of c plug gauge: ¢D=Rm-1=15.1-1=14.1≈14.

[0079] This measurement method is suitable for countersinking or reaming on small holes, and the measurement of a large number of holes. It is more common in aviation products. The size calculation of the plug gauge is simple, easy to understand, simple in structure, easy to manufacture, and convenient to use, etc. advantage. However, if the processed hole is too large, it will be difficult to manufacture and use, and this method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com