Resin powder including ultraviolet scattering agent, production method therefor, and cosmetic

A technology of resin powder and ultraviolet rays, which is applied in the direction of medical preparations, cosmetics, and cosmetic preparations containing active ingredients, can solve the problems of reduced ultraviolet scattering, increased viscosity of cosmetic materials, and reduced ultraviolet scattering, so as to inhibit the skin Direct contact, high practicability and effectiveness, and high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102]Use titanium oxide particles [titanium dioxide, manufactured by Dupont, Ti-Pure (R) Titanium Dioxide Pigment-Paint Coatings-DryGradesR-105, surface treatment (silica, alumina dimethyl siloxane treatment) product] 50 parts by weight, polyamide Resin (polyamide 12, manufactured by Daicel-Evonik) 50 parts by weight, the same as Example 1 of Japanese Patent Application Laid-Open No. 2005-179646, obtained polyamide particles (spherical shape, average particle diameter 4.1 μm, The proportion of titanium oxide particles is 50% by weight).

[0103] Then, plate formation was performed by crushing the obtained particles in water at a ratio of 10% by weight using a ball mill. It should be noted that the medium type of the ball mill used at this time used high-purity alumina beads (particle diameter: 0.5 mm), and the volume of the dispersion liquid was the same as the volume of the medium.

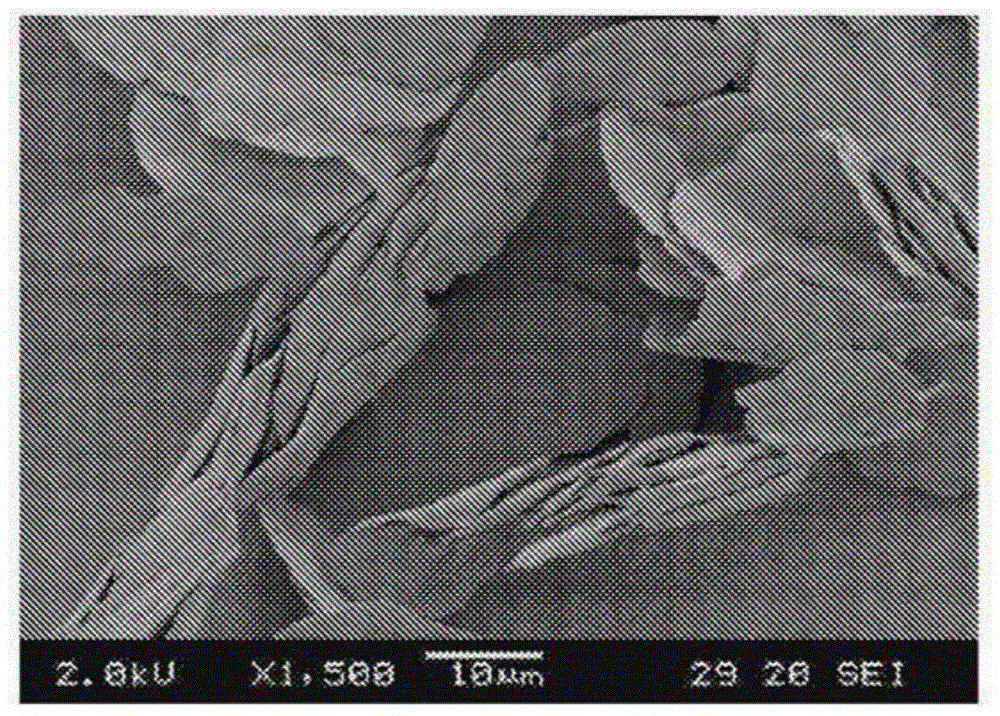

[0104] figure 1 An electron micrograph (1500 times) of the obtained platy powder is shown....

Embodiment 2

[0111] In addition to using 50 parts by weight of zinc oxide particles (average particle diameter 20 nm, manufactured by Sakai Chemical Industry Co., Ltd., "FINEX-50S-LP2", surface-treated (organopolysiloxane) product) instead of titanium oxide in Example 1 , and in the same manner as in Example 1, polyamide particles containing zinc oxide particles (spherical shape, average particle diameter 4.5 μm, ratio of zinc oxide particles 50% by weight) were obtained.

[0112] Furthermore, the obtained pellets were formed into plates in the same manner as in Example 1.

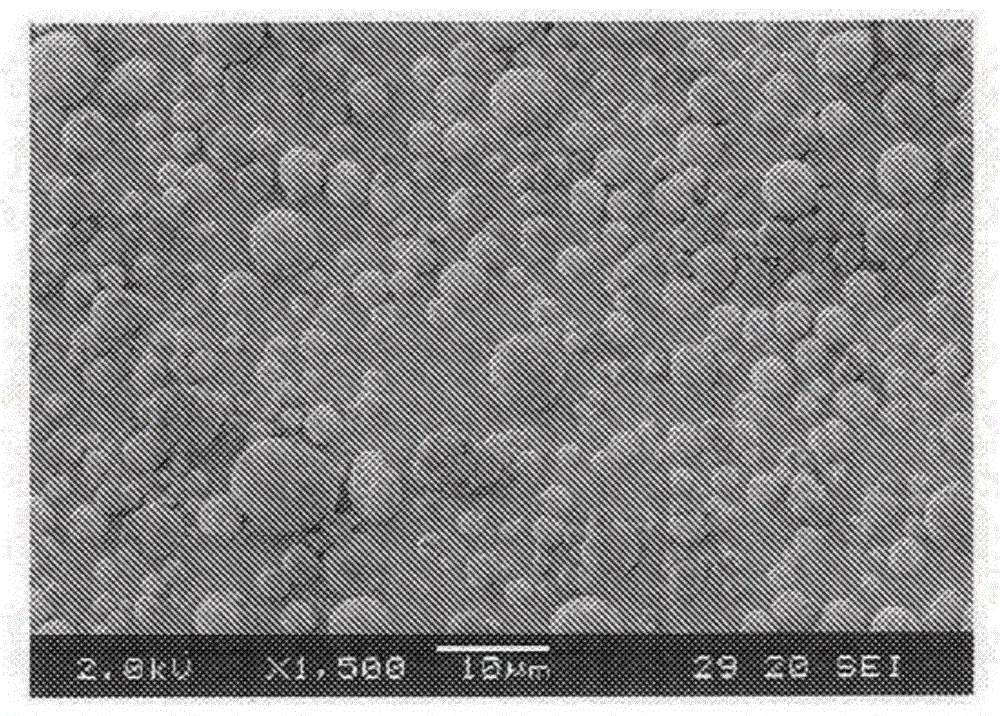

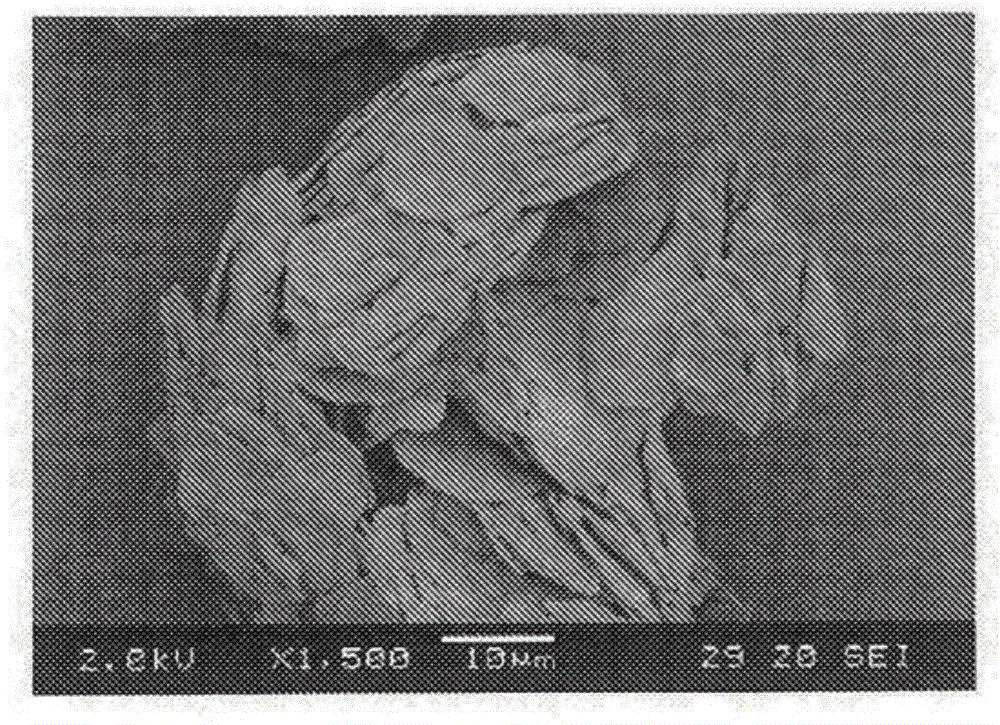

[0113] image 3 An electron micrograph (1500 times) of the obtained platy powder is shown. It should be noted that, for comparison, Figure 4 An electron micrograph (magnification 1500) of polyamide particles themselves (polyamide particles before plate-forming treatment) including zinc oxide particles is also shown. As is clear from these photographs, each polyamide pellet was plated.

[0114] It should be noted t...

Embodiment 3

[0119] Except changing the polyamide resin in embodiment 1 from 50 parts by weight to 40 parts by weight, it is the same as in embodiment 1 to obtain polyamide particles (spherical shape, average particle diameter of 4.5 μm, the size of titanium oxide particles) comprising titanium oxide particles The proportion is 55% by weight).

[0120] Furthermore, the obtained pellets were formed into plates in the same manner as in Example 1. The average thickness of the plate-shaped powder was 1.1 μm, and the average diameter was 29 μm.

[0121] In addition, when the UV transmittance was measured in the same manner as in Example 1, it was 28% at 300 nm, 28% at 330 nm, 28% at 360 nm, and 29% at 400 nm.

[0122] It should be noted that when the ultraviolet transmittance of the polyamide particles themselves (polyamide particles before plate treatment) containing titanium oxide particles was measured by the same method, it was 42% at 300nm and 42% at 330nm, 40% at 360nm and 41% at 400nm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com