Glue injection head and glue injection machine with same

A technology of glue injection head and glue injection machine, which is applied in the field of glue injection head and glue injection machine with it, and can solve the problems of glue dripping, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] According to the following detailed description of specific embodiments of the present invention in conjunction with the accompanying drawings, those skilled in the art will be more aware of the above and other objects, advantages and features of the present invention.

[0021] Current glue injection machines all have a glue injection head 100, but for the existing glue injection machine, the inventor is in the process of using, after the glue injection head 100 in the prior art stops glue injection, there will be a certain amount of glue Keep dripping. After research and analysis, the inventor believes that the reason for this phenomenon is that due to the inertia of the glue in the glue injection machine, the glue will continue to move out of the glue injection head 100 when the glue injection is stopped. For this reason, the inventor of the present invention has proposed following technical scheme:

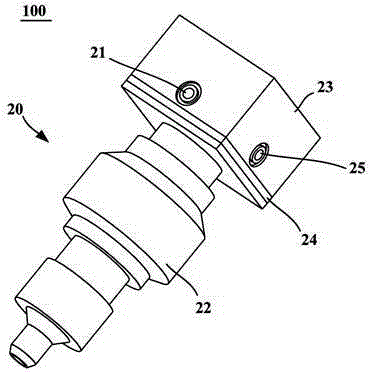

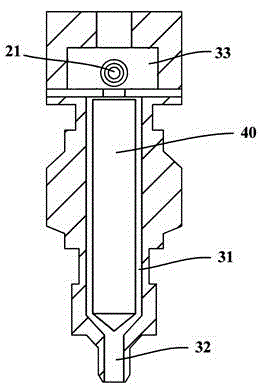

[0022] figure 1 It is a glue injection head 100 for a glue inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com