Portable ultrasonic cutter

An ultrasonic, portable technology, applied in metal processing and other directions, can solve the problems of chipping, cracks, tool hair heating, etc., to achieve the effect of high speed, high power and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

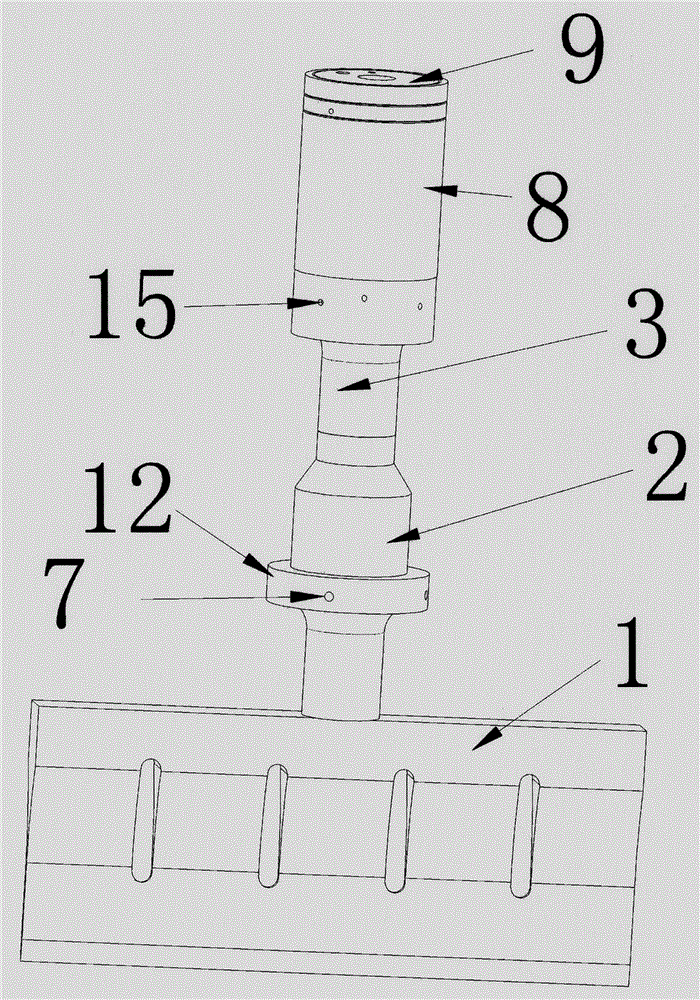

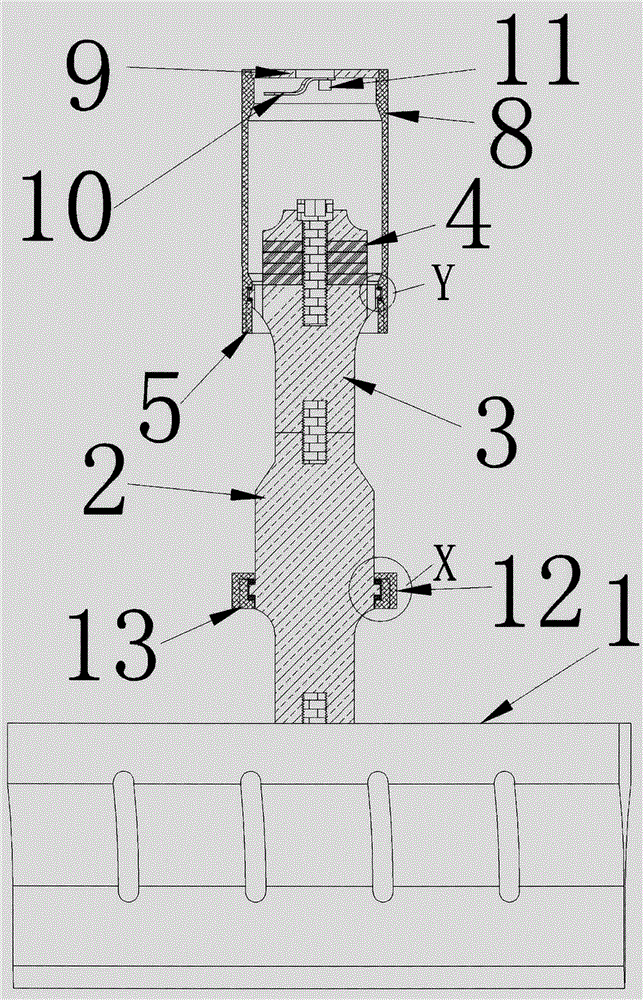

[0037] Below in conjunction with accompanying drawing, the present invention will be further described

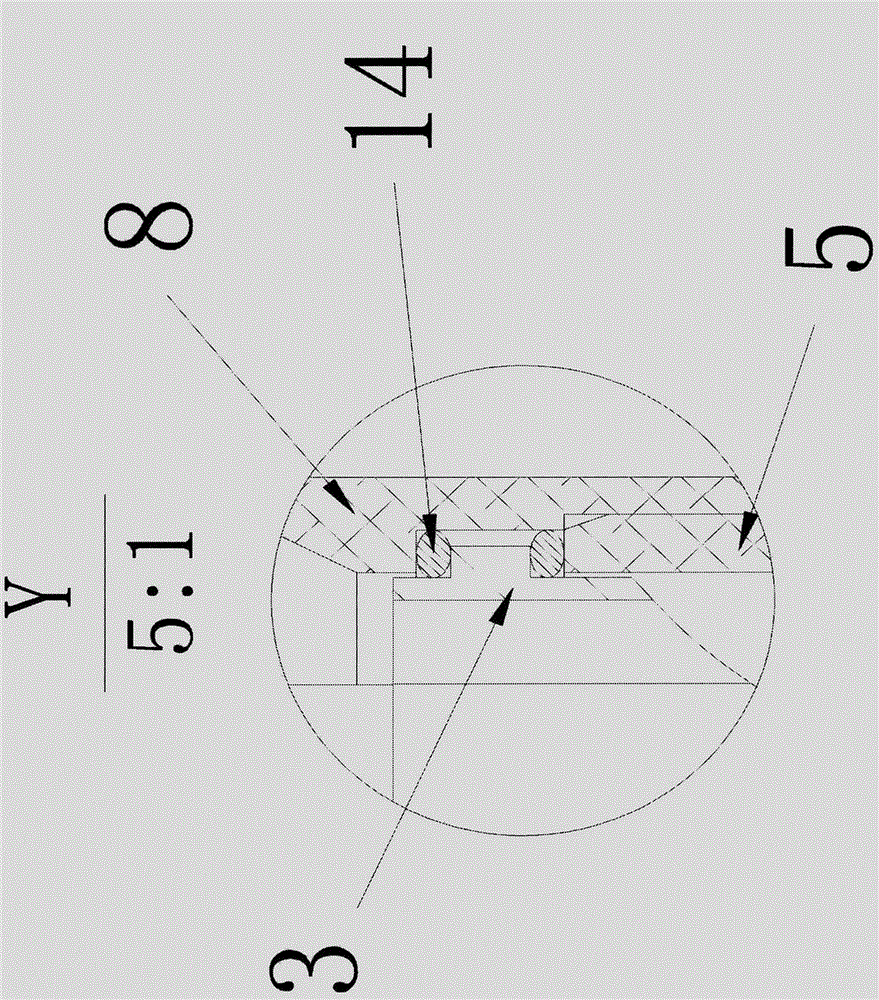

[0038] figure 1 and figure 2 Shown: a portable ultrasonic cutter, including a piezoelectric ceramic transducer 4 connected to a 1 / 4 wavelength horn 3 through a high-strength screw, and the other end of the 1 / 4 wavelength horn 3 is connected to a half-wavelength horn by a bolt The large end of the rod 2 and the small end of the half-wavelength horn 2 are connected to the tool head 1 through bolts, and there is a zero vibration point position on the half-wavelength horn 2 (the zero vibration point position here means the place where the horn does not vibrate ), the upper and lower positions of the zero vibration point are equipped with O-rings A6, which are tightened by the interference fit of the fastening upper ring 12 and the fastening lower ring 13, and the fastening upper ring 12 and the fastening lower ring 13 are ultrasonic cutters The position fixed on the equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com