Portable ultrasonic handheld cutter

An ultrasonic and portable technology, applied in metal processing and other directions, can solve problems such as cracks, tool hair heating, edge collapse, etc., and achieve the effects of long service life, stable work and good formability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

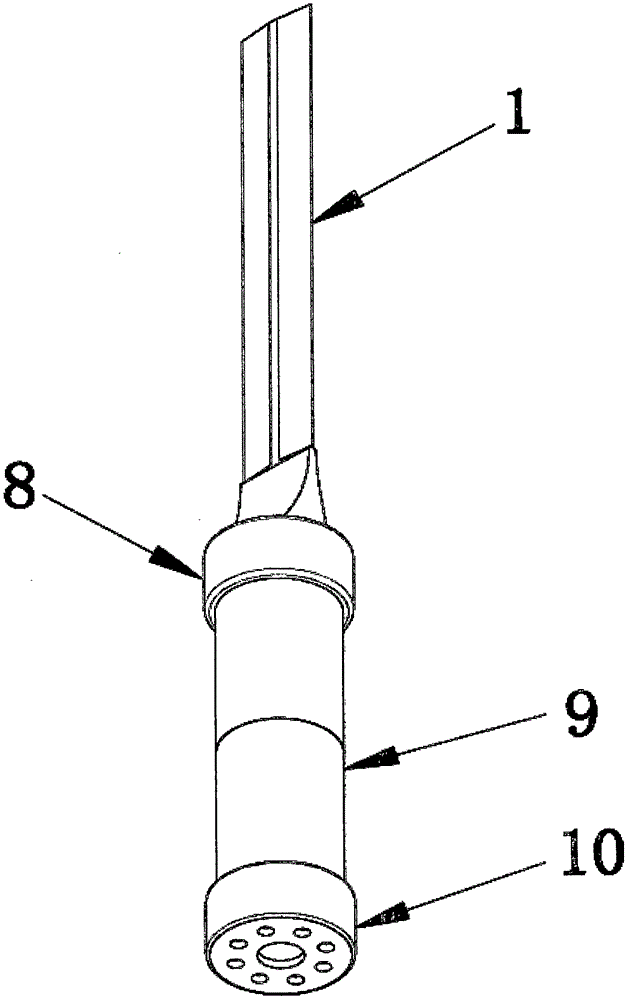

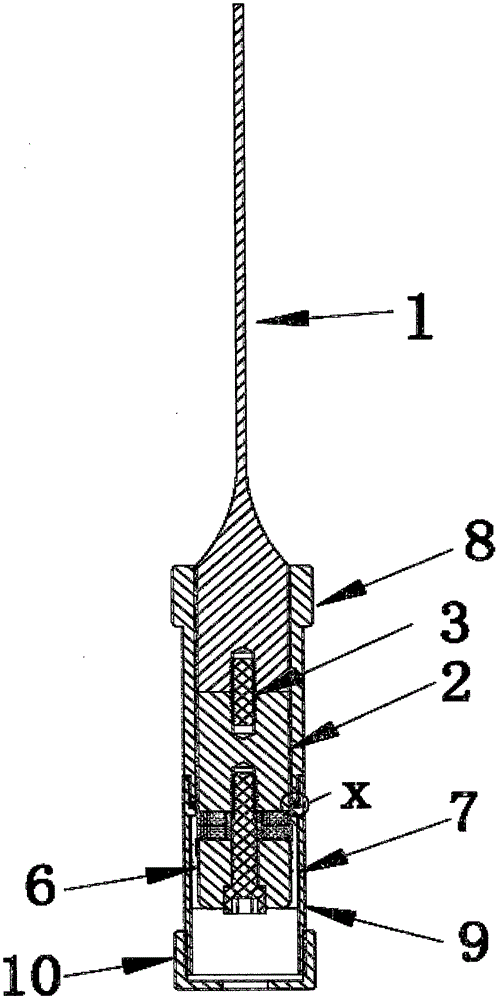

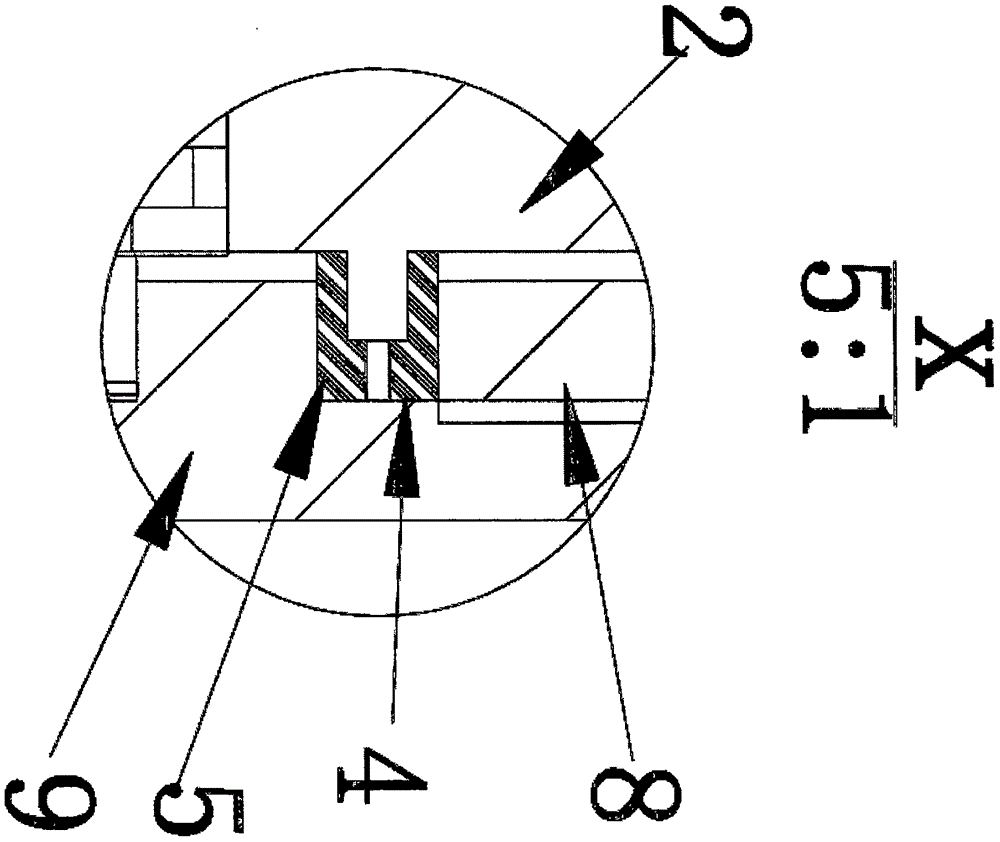

[0030] Below in conjunction with accompanying drawing, the present invention will be further described

[0031] figure 1 , figure 2 and image 3 Shown: a portable ultrasonic hand-held cutter, including a piezoelectric ceramic transducer 2 connected to the tool head 1 through a 12.9-grade high-strength screw 3, and a nylon washer A4 is installed on the zero-vibration point of the front cover of the piezoelectric ceramic transducer 2 , the nylon washer B5 is installed below, the transducer middle cylinder 9 and the transducer upper cylinder 8 press the nylon washer A4 and the nylon washer B5 through screw fit, and the piezoelectric ceramic transducer 2 is fixed on the transducer housing. Inside, the inner side of the transducer tube 9 is equipped with an insulating sleeve B7, and the surface of the piezoelectric ceramic transducer 2 ceramic sheet is equipped with an insulating sleeve A6 to prevent the electrodes from connecting with the metal. 9 Through threaded connection, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com