A polymer battery car frame

A battery car and polymer technology, which is applied in the automotive field, can solve the problems affecting the specific gravity of the front and rear bearings of the vehicle, the unbalanced weight of the bearing, and waste, so as to improve the utilization rate of car space, solve the difficulty of layout, and increase the space capacity of the battery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

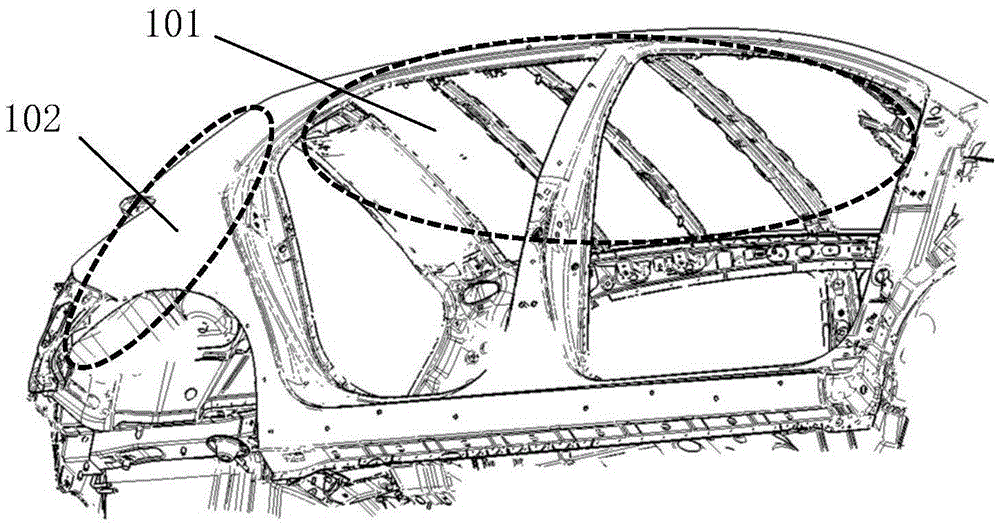

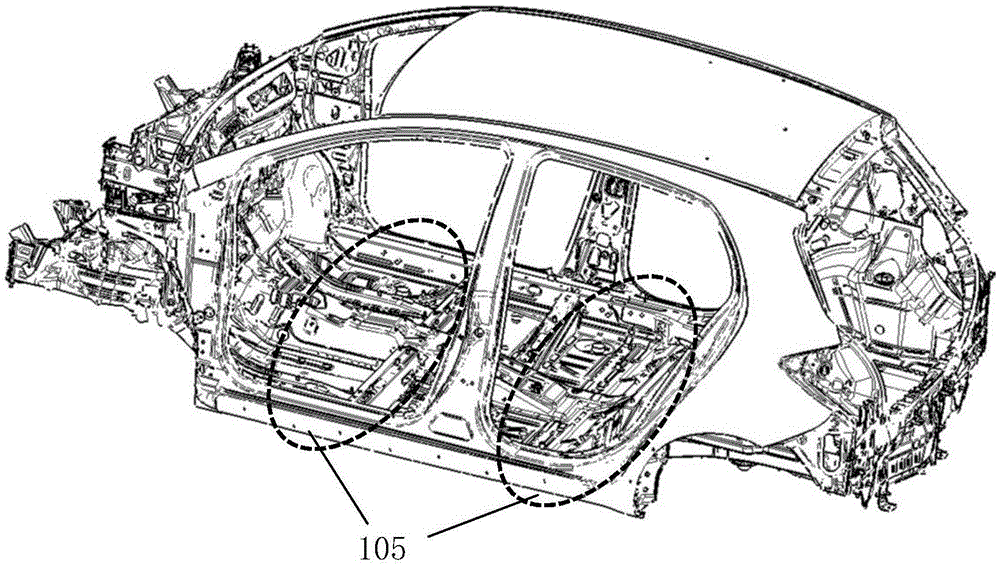

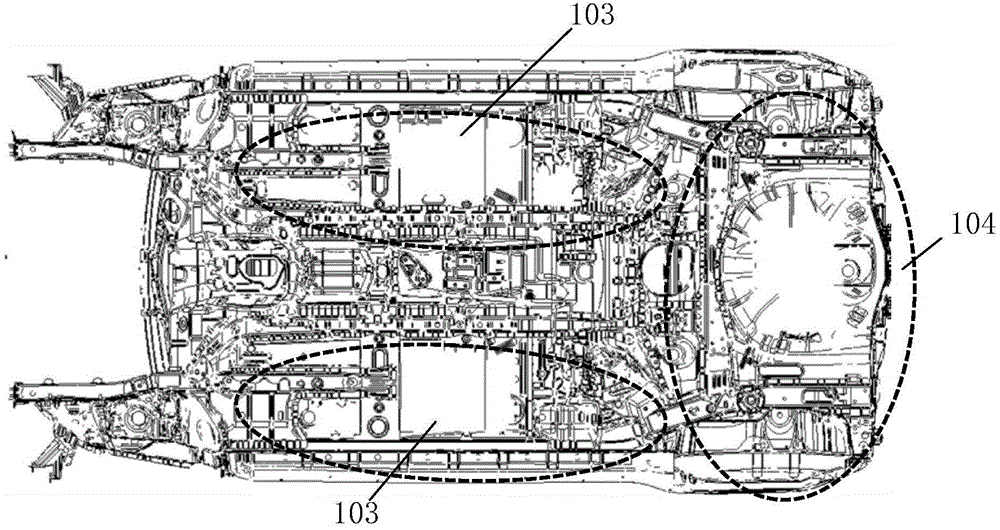

[0024] see figure 1 , figure 2 , image 3 as well as Figure 4 , the polymer battery vehicle frame of the present invention includes a polymer battery and a vehicle frame, and the polymer battery is arranged inside the vehicle frame top cover 101, inside the fender 102, above the floor 103, below the floor 103, and the spare tire compartment Inside of 104, outside of spare tire compartment 104, inside of central tunnel 105, outside of central tunnel 105, front of lower body of body, inside of side panel, inside of four doors, outside of longitudinal beam, outside of cross beam And the inside of the trunk outer panel, the polymer battery includes an asphalt mixture patch 1, a cell 2 and a battery protection plate 3, the asphalt mixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com