Crotch hot mold pressing process of men's underpants and men's underpants

A technology of thermal molding and underwear, which is applied in the field of garment processing, can solve the problems of uncomfortable wearing experience of men's underwear, achieve the effect of improving product standardization, simple process, and avoiding wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

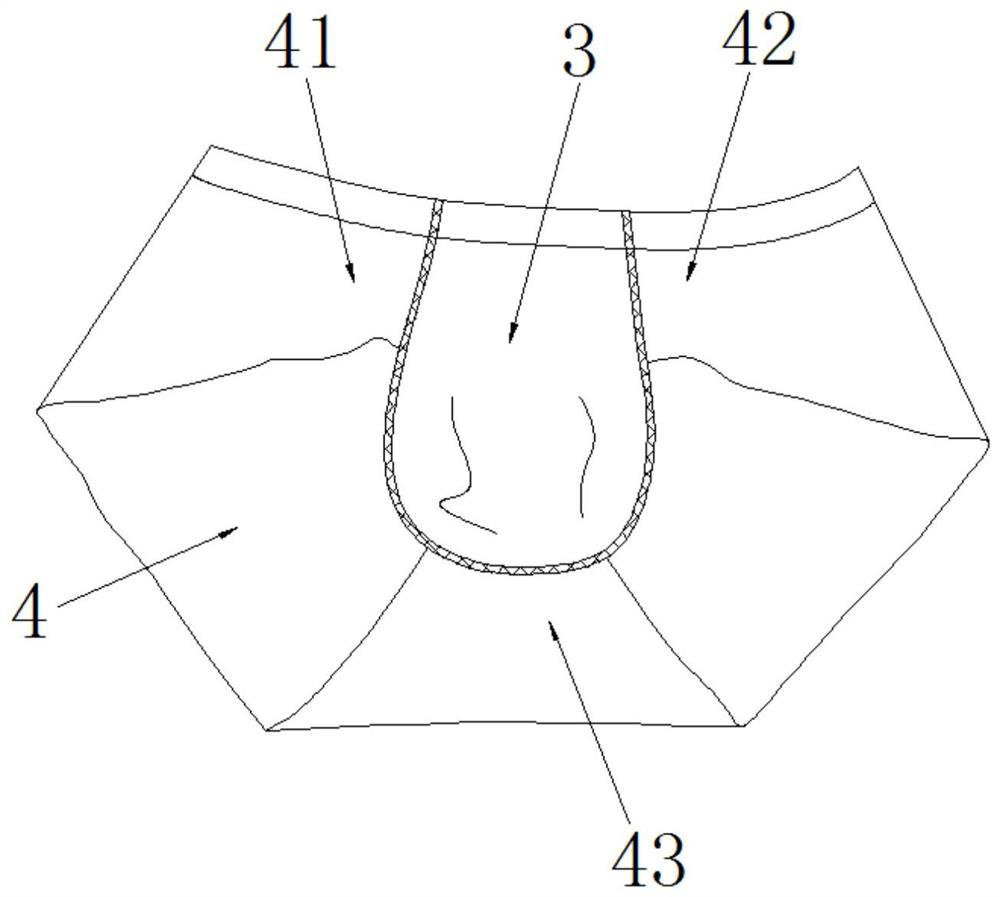

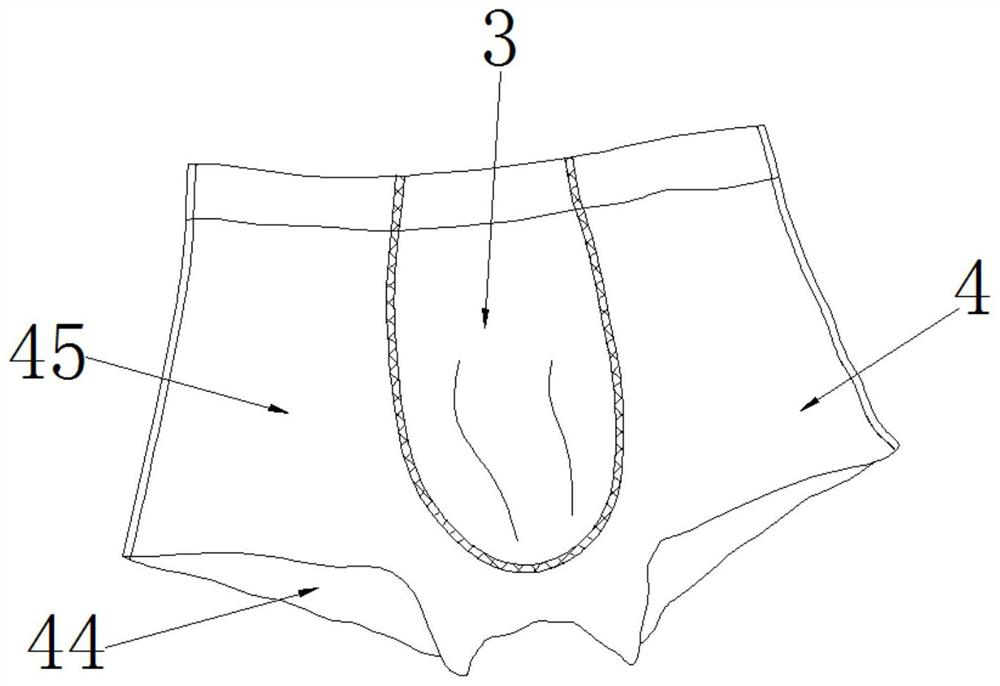

[0036] The invention provides a crotch thermal molding process for men's underwear, comprising the following steps:

[0037] Step A: raw material preparation, cutting the knitted fabric into a square piece 1, and distinguishing the front and back of the square piece 1;

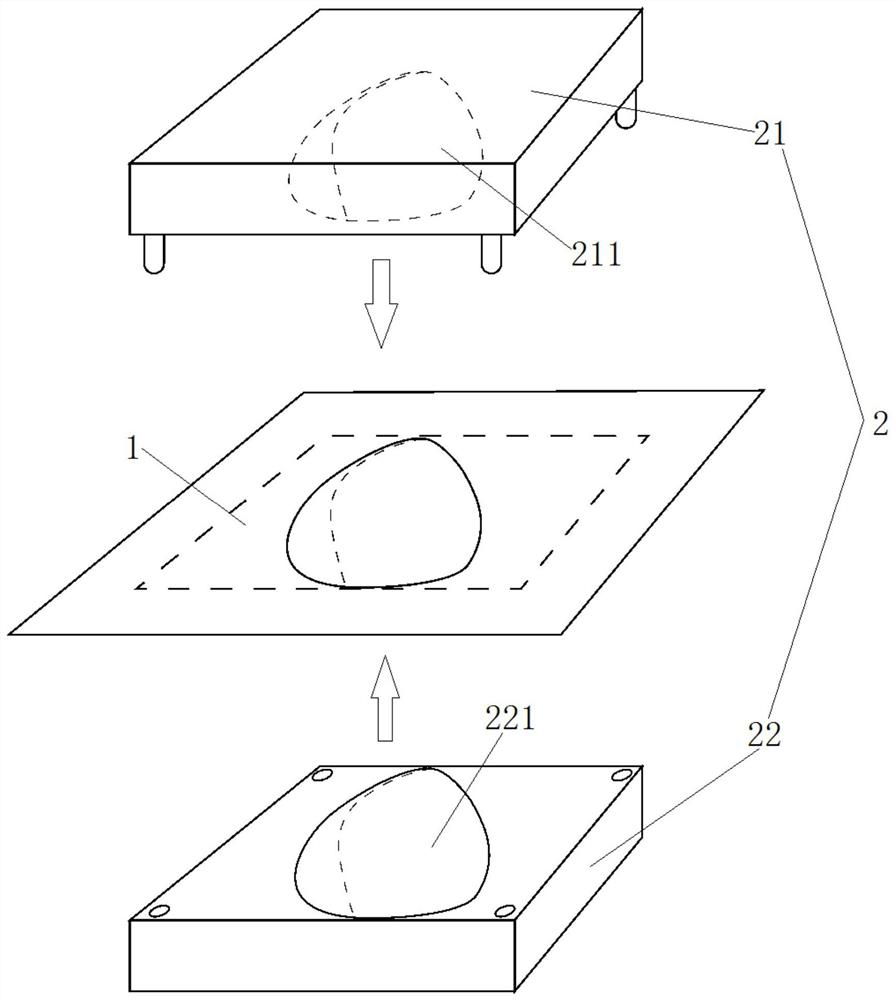

[0038] Step B: Preliminary molding of the front crotch part 3, after heating the three-dimensional oval molding mold 2 to the specified temperature, separating the pressing mold 21 and the supporting mold 22 in the three-dimensional oval molding mold 2, and then separating the square sheet 1 Place it on the supporting mold 22 and close the pressing mold 21 and the supporting mold 22, so that the square sheet 1 is hot-pressed and deformed. After heating for a specified period of time, open the three-dimensional oval molding mold 2, and heat-press the deformed Take out the square piece 1;

[0039] Step C: It is necessary to screen the hot-pressed and deformed square sheet 1, remove the defective products, and p...

Embodiment 2

[0041] As an optional embodiment, the front crotch 3 is made of elastic material, and after being washed and deformed, the front crotch 3 will retract slightly. Manual shirring can appropriately increase the space capacity and offset the shrinkage of washing and wearing deformation. After testing and comparison, the length of the bottom arc with a shrinkage of 1.5-3cm is suitable.

[0042] As an optional implementation, in step B, the heating temperature of the three-dimensional oval molding die 2 is 190°±3°, and the heating time for the square sheet 1 is 38s to 45s. In addition, the specific temperature duration can be determined according to the square sheet 1 to adjust the thickness and composition ratio.

[0043] As an optional implementation, in step B, the square sheet 1 needs to be treated with a high temperature resistance additive before hot pressing, and the high temperature resistance additive can prevent the square sheet 1 from yellowing and blackening during the h...

Embodiment 3

[0046] As an optional embodiment, the three-dimensional oval molding die 2 is provided with a heating device, the heating device can be a heating wire, the pressing mold 21 can be provided with a heating device, and there is no heating device on the supporting mold 22; or the supporting mold 22 can be provided with a heating device, but there is no heating device on the pressing die 21; or both the pressing die 21 and the supporting die 22 are provided with a heating device.

[0047] As an optional embodiment, the pressing mold 21 is provided with an outwardly protruding semi-oval portion 211, and the supporting mold 22 is provided with an inwardly recessed semi-oval groove 221, the semi-oval portion 211 can extend into half Oval groove 221 and the two match. The square sheet 1 is placed between the semi-oval portion 211 and the semi-oval groove 221, and then the semi-oval portion 211 and the semi-oval groove 221 can heat-press the square sheet 1 into a semi-oval structure. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com