Multistep pressure coding detonating method and device for well perforation

A detonation method and pressure technology, which are used in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problem that the delay time of detonation cannot be changed, the monitoring of the underground working environment cannot be realized, the test joint cannot be performed, and the pump cannot be used. Perforating and perforating technology and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

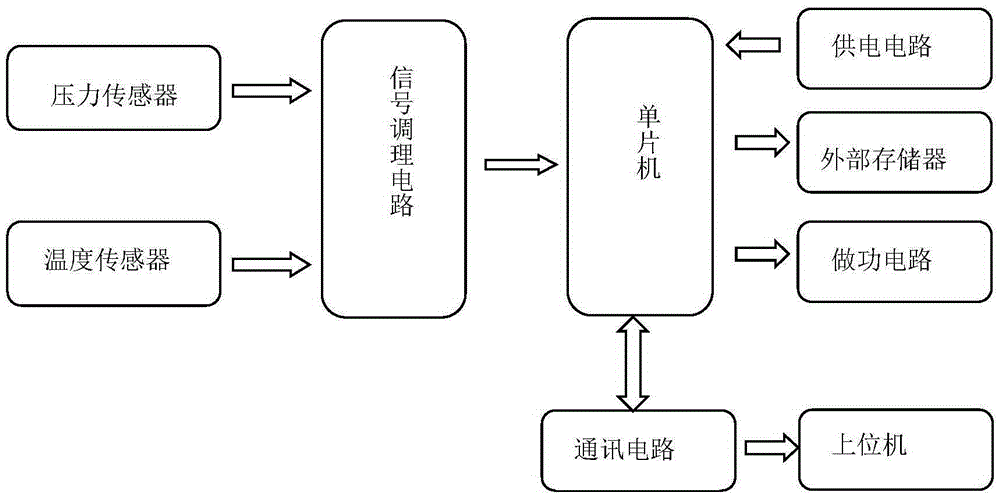

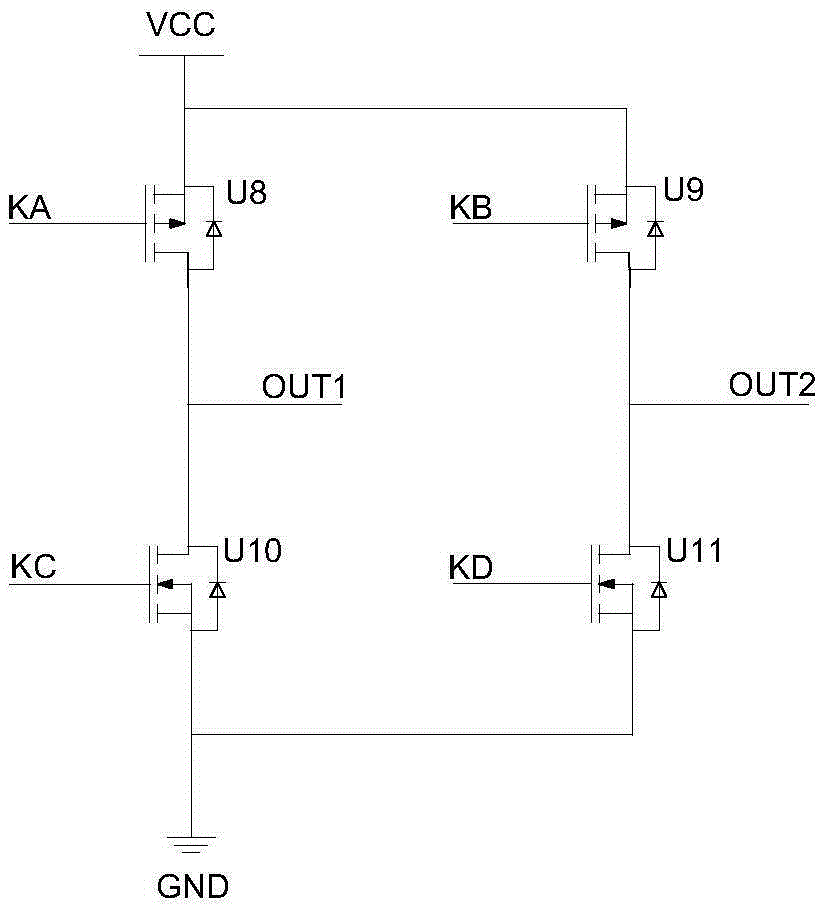

[0044] attached figure 1 It is a functional block diagram of the device for the multi-stage pressure coding detonation method of oil well perforation according to the present invention, including pressure sensor, temperature sensor, signal conditioning circuit, single-chip microcomputer, power supply circuit, external storage, working circuit and communication circuit. The working circuit includes four field effect transistors U8, U9, U10 and U11, the four field effect transistors are connected with the source and drain to form a bridge connection, and the connection between the source of U8 and the drain of U10 is the output terminal OUT1. The connection end of the source of U9 and the drain of U11 is the output terminal OUT2, and the grids KA, KB, KC, and KD of the four field effect transistors are respectively connected with the I / O ports of the single-chip mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com