Method and device for fatigue testing of exhaust valve disc

A fatigue test and exhaust valve technology, applied in the direction of measuring device, mechanical component test, machine/structural component test, etc., can solve the problem of small impact speed of valve plate, insignificant test effect, and inability to obtain better test effect, etc. problem, to achieve the effect of accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

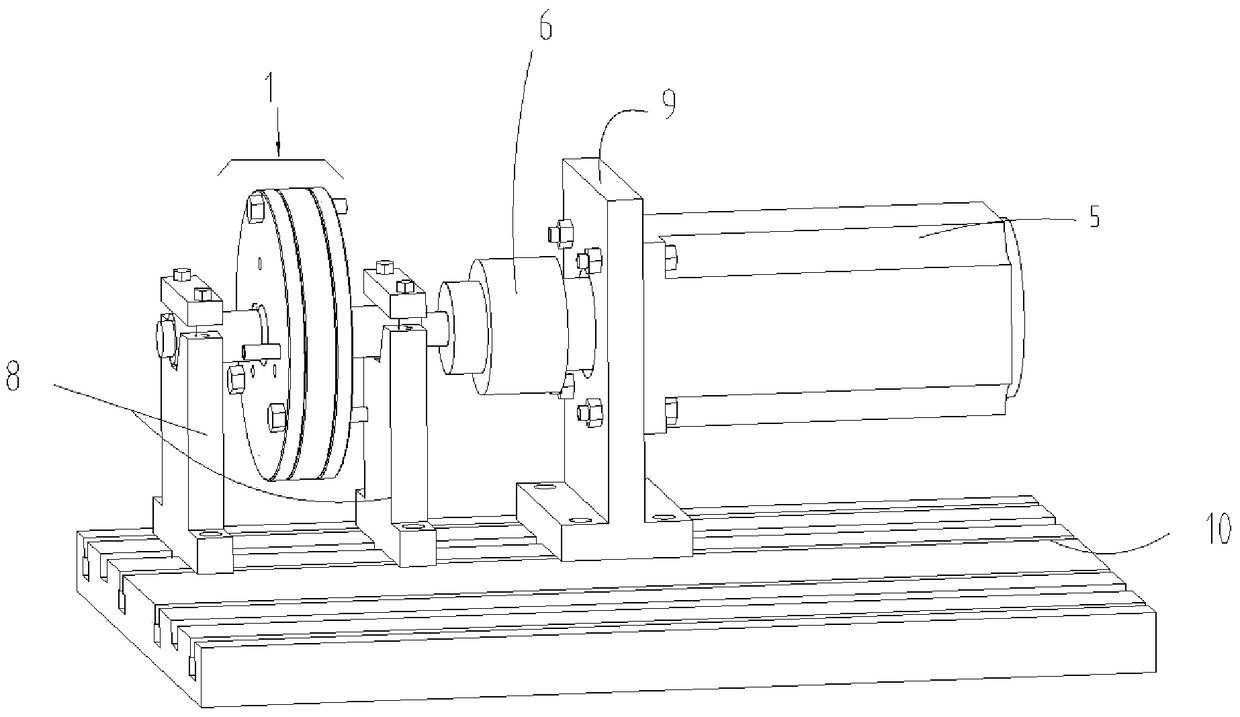

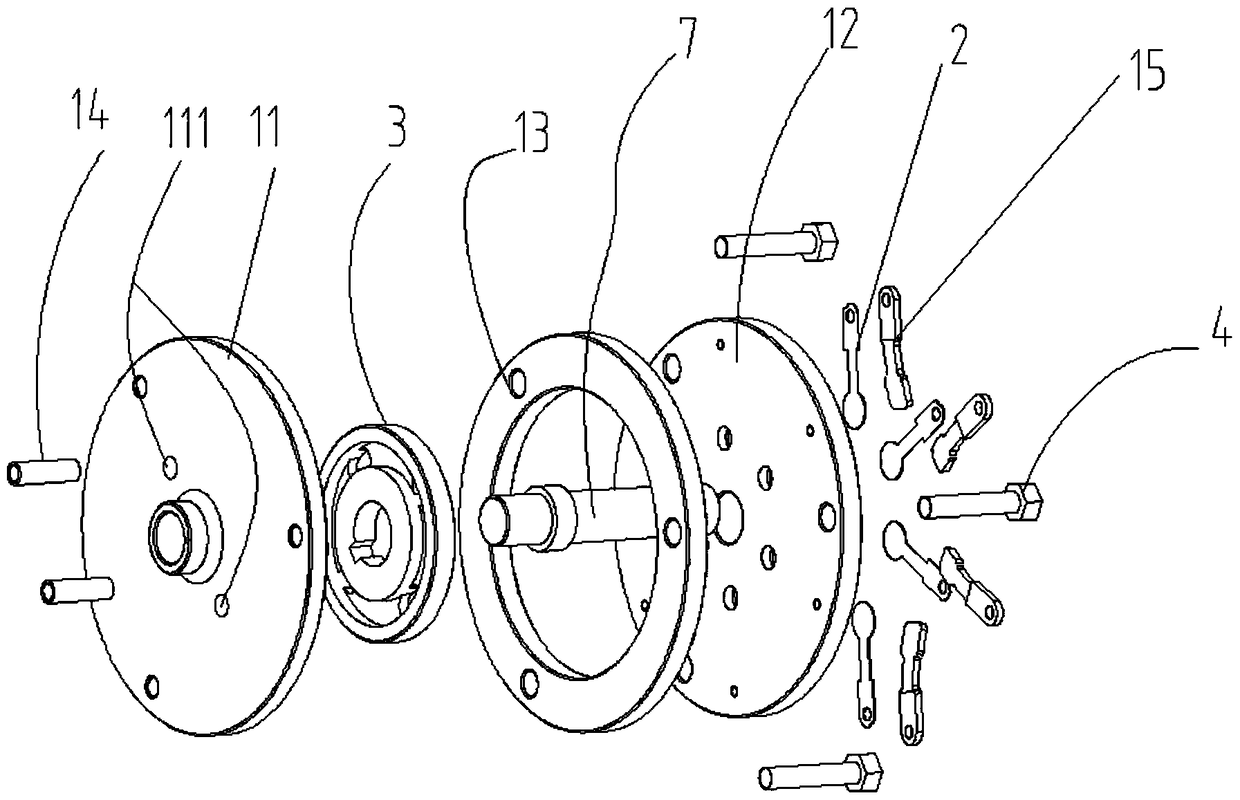

[0040] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

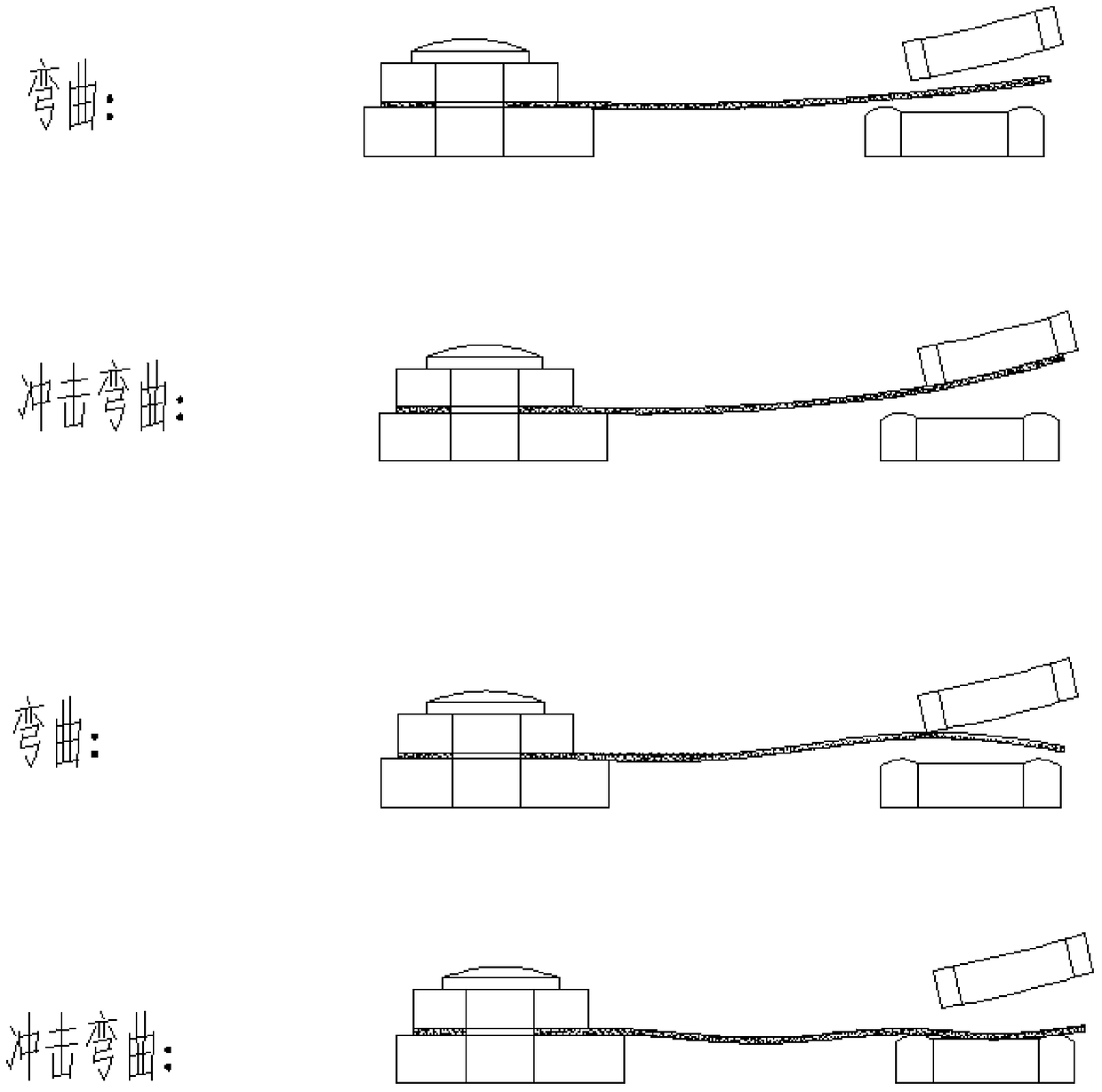

[0041] The present invention provides a fatigue test method for the valve plate of the exhaust valve, which fixes one end of the valve plate and performs the following actions in a cycle:

[0042] Exhaust action, using compressed air to impact the free end of the valve plate, causing the valve plate to bend, simulating the shape of the valve plate when it is exhausted;

[0043] The reset action stops the impact of compressed air on the free end of the valve plate, and the free end of the valve plate resets, simulating the reset state of the valve plate stopping exhaust.

[0044] The above-mentioned exhaust and reset actions are carried out cyclically by the valve plate to accurately simulate the force of the valve plate, so as to truly evaluate the reliability of the exhaust structure and materials,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com