Detachable stirring tank bottom bearing

A technology of stirring tank and bottom bearing, which is applied in the directions of mixer accessories, mixer, dissolving, etc., to achieve the effect of easy replacement and maintenance, convenient height adjustment, and avoiding welding operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

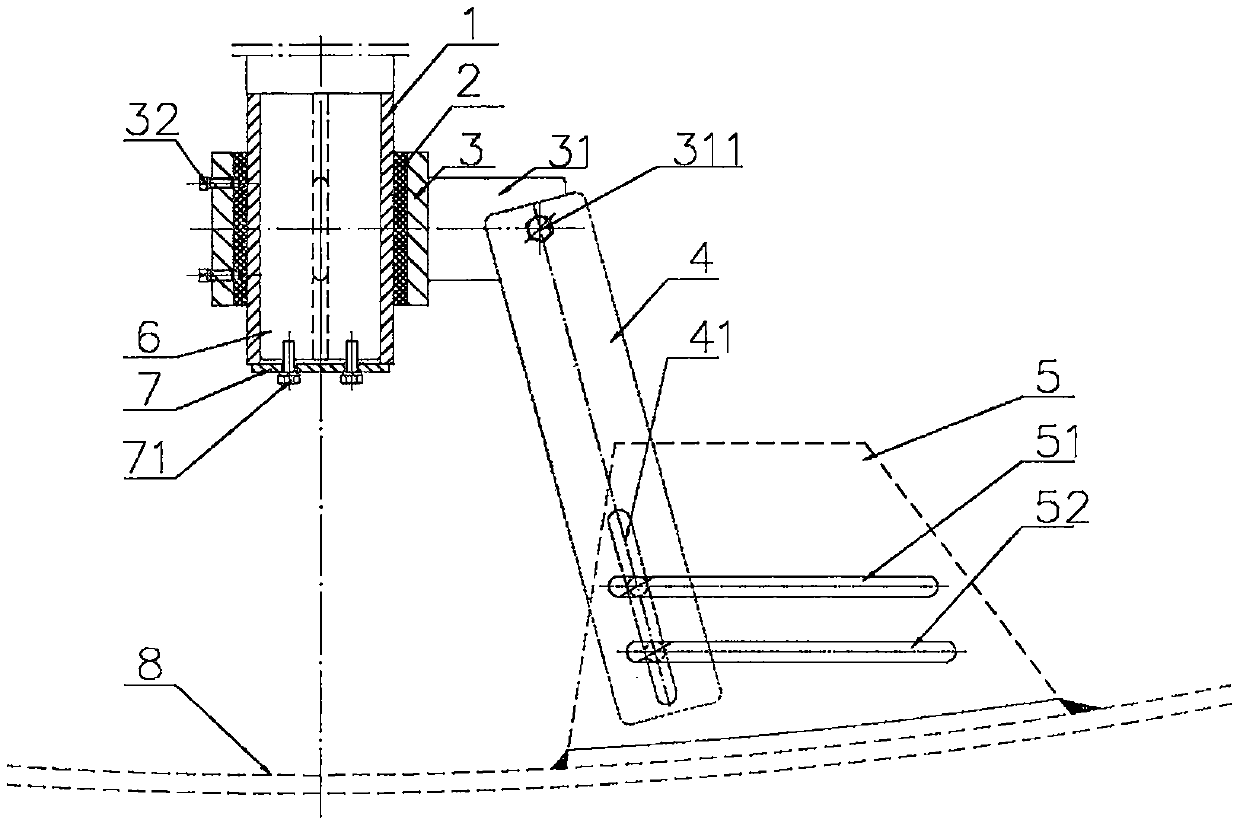

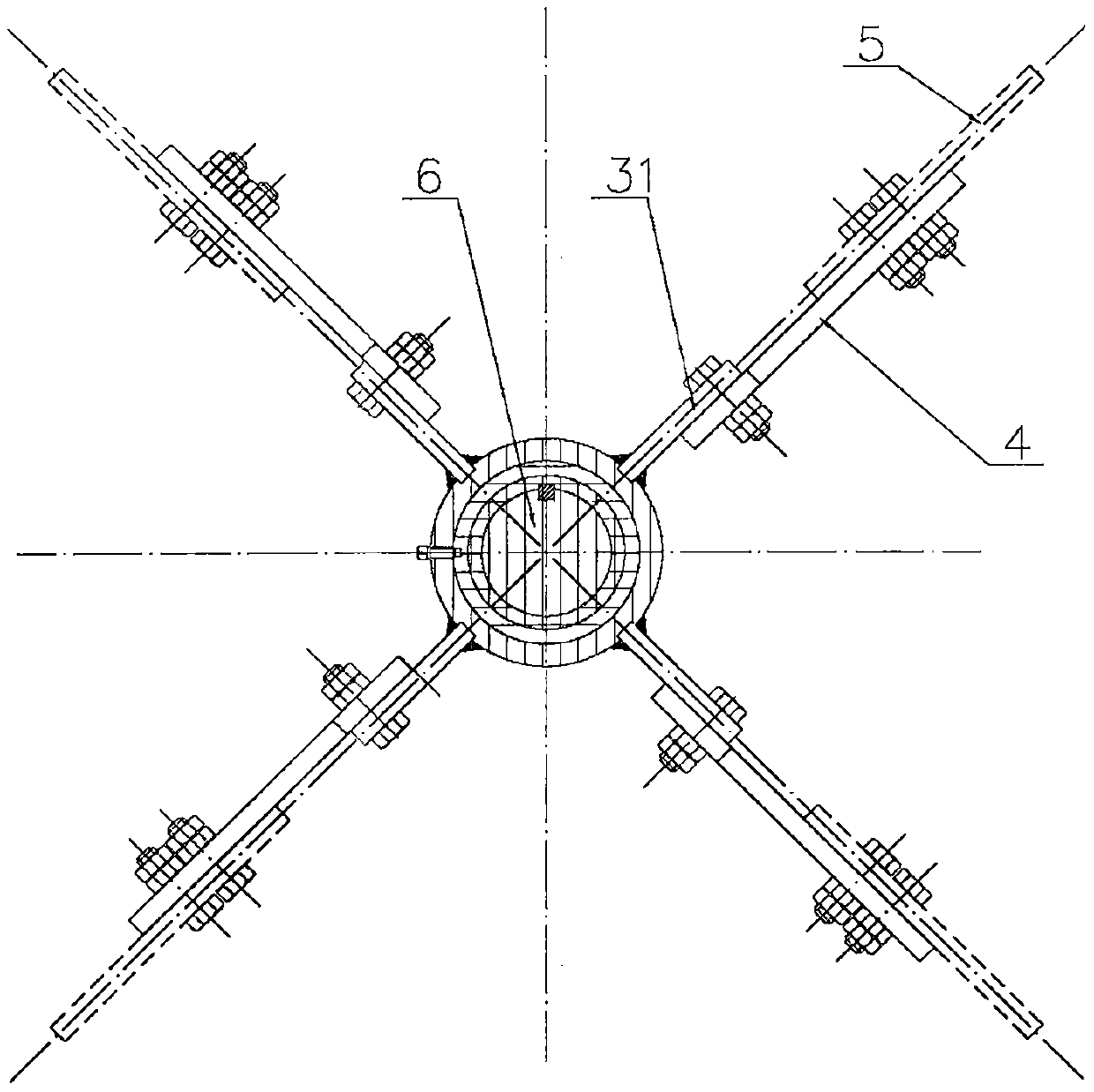

[0011] An embodiment of the present invention will be described below in conjunction with the accompanying drawings.

[0012] The detachable stirred tank bottom bearing shown in the figure includes a sheath (1), a shaft sleeve (2), a bearing seat (3), a support plate (4) and an embedded plate (5), and the sheath (1) is installed and fixed At the end section of the shaft (6), the sleeve (2) which is slidingly matched with it on the periphery is fixed in the bearing seat (3) by means of the set screw (32) at the cylindrical end, and the embedded plate (5) is welded on the wall of the kettle (8 ), the bearing seat (3) is connected to the embedded plate (5) through the fixed plate (31) and the support plate (4) welded together with it, and the two ends of the support plate (4) are respectively connected to the fixed plate (31) and the pre-embedded plate The buried plate (5) is fastened and connected by means of bolts and nuts. The bolt holes used to connect the support plate (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com