High-temperature gasification product quenching shift purification device and its process method

A purification device and chilling technology, which is used in combustible gas purification, combustible gas purification/transformation, chemical industry, etc., to reduce equipment investment and operation and maintenance costs, improve removal rate, and reduce fly ash entrainment rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

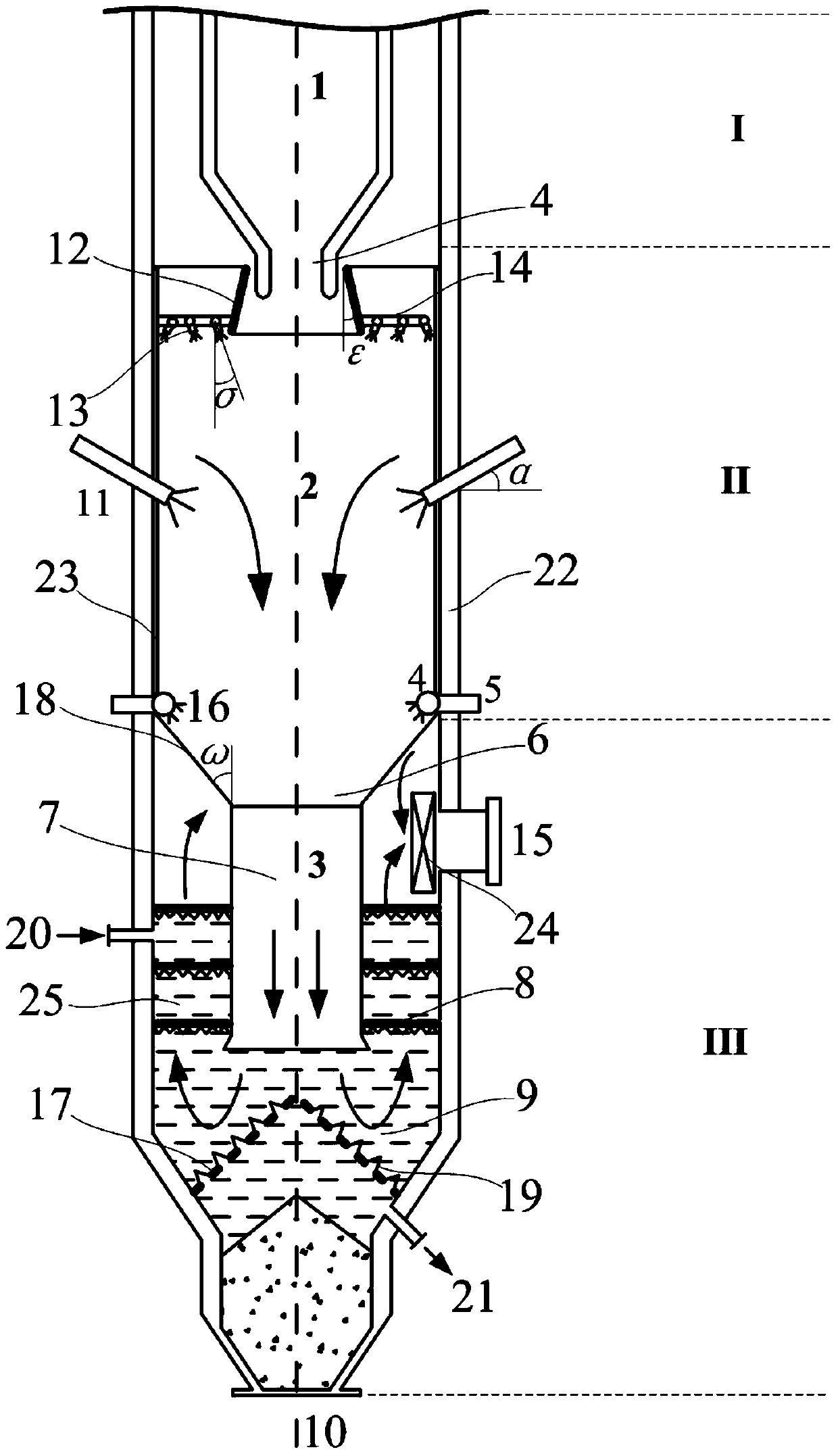

[0046] It is equipped with a dry pulverized coal pressurized entrained gasifier with a daily coal processing capacity of 2,000 tons, and the synthesis gas is pretreated by using the high-temperature gasification product chilling conversion purification device described in the present invention.

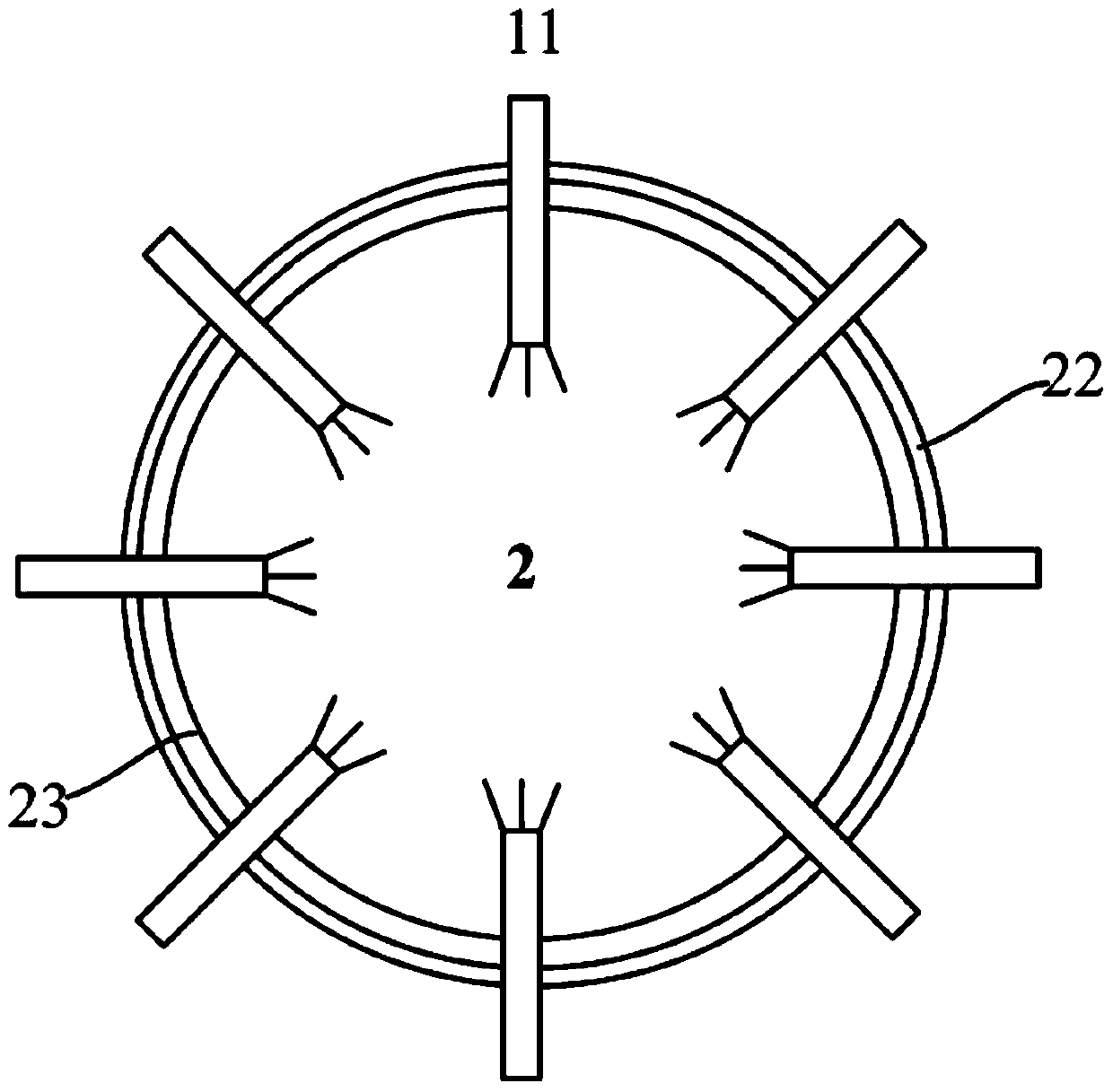

[0047] The cylinder diameter of the syngas quenching conversion chamber is 2800 mm. The quenching ring 14 is provided with three layers. Each quenching nozzle 13 is evenly arranged along the quenching ring 14. 48 are sprayed with liquid water. The outer layer has an outward angle of 15°. The layer is vertically downward, the angle of the inner layer is -15°, and the jet velocity is about 5m / s.

[0048] A total of 8 side chilling spray guns are evenly arranged in one layer, and the spray speed is 3.5m / s.

[0049] About 50t / h cooling water is sprayed into the bottom quenching ring.

[0050] The washing and deslagging chamber is sprayed with liquid water at 120°C at 4.0Mpa.

[0051] Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com