A fuel cell humidification system

A fuel cell and electrical connection technology, which is applied to fuel cells, circuits, electrical components, etc., can solve problems such as difficult humidity adjustment, and achieve the effects of high spray atomization quality, simple processing technology and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

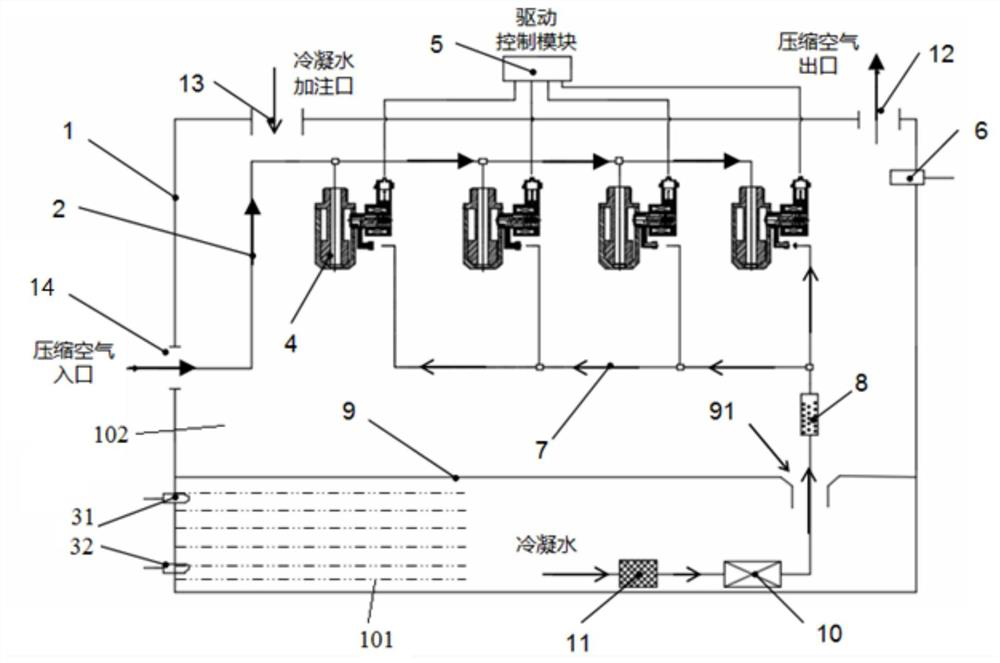

[0037] Such as Figure 1-4 As shown, the present invention provides a fuel cell humidification system, which includes:

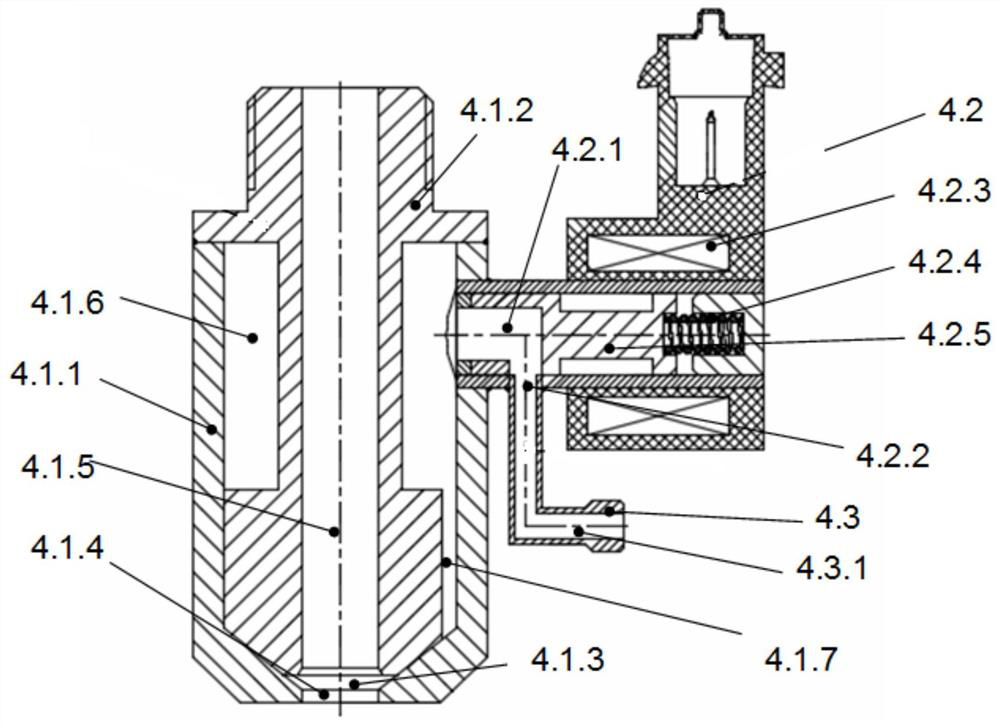

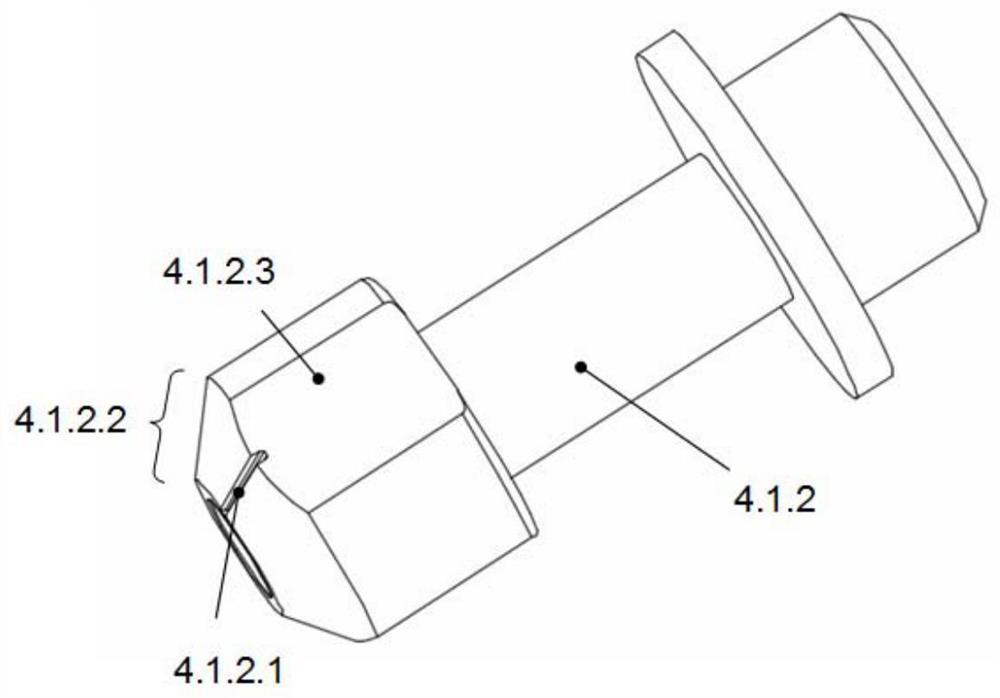

[0038]Water tank 1, the inside of the water tank 1 is provided with a water tank partition 9, the lower part of the water tank partition 9 is a water storage space 101, and the top of the water tank partition 9 is provided with a dual-fluid injector 4, and the dual-fluid injector 4 has a water inlet and communicates with the water storage space 101 to allow the water in the water storage space 101 to be passed into the dual-fluid injector 4; the upper side of the water tank 1 is provided with a compressed air inlet 14 , compressed air enters the upper space 102 of the water tank partition 9 from the compressed air inlet 14, and the dual-fluid injector 4 has an air inlet to allow the compressed air to be passed into the dual-fluid injector 4 Water and compressed air are mixed in the two-fluid injector 4 and are discharged into the upper space, and the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com